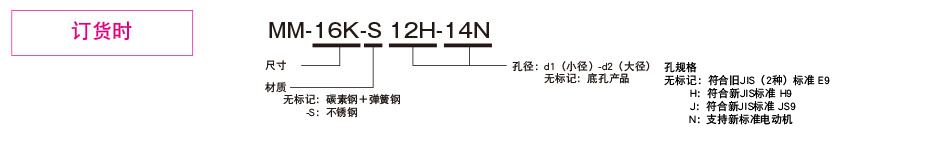

MM型

金属螺旋弹簧部分采用3层结构,小巧而能传递高转矩。备有毂材质采用SUM24L或相当产品、螺旋弹簧材质采用钢琴线的型号(MM-K型)和为提高耐腐蚀性而采用不锈钢作为毂和螺旋弹簧的材质的型号(MM-K-S型),可根据使用环境进行选择。

金属螺旋弹簧部分采用3层结构,小巧而能传递高转矩。备有毂材质采用SUM24L或相当产品、螺旋弹簧材质采用钢琴线的型号(MM-K型)和为提高耐腐蚀性而采用不锈钢作为毂和螺旋弹簧的材质的型号(MM-K-S型),可根据使用环境进行选择。

MM 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 转动惯量[kg•m2] | 质量[kg] | ||

|---|---|---|---|---|---|---|---|---|

| 偏心[mm] | 偏角[°] | 轴向[mm] | ||||||

| MM-6K | 2.5 | 0.3 | 3 | +0.6 | 20000 | 143 | 7.65×10-7 | 0.03 |

| MM-8K | 5 | 0.3 | 3 | +0.8 | 15000 | 286.5 | 4.08×10-6 | 0.07 |

| MM-12K | 10 | 0.4 | 3 | +1.0 | 12000 | 573 | 1.43×10-5 | 0.14 |

| MM-14K | 10 | 0.5 | 3 | +1.0 | 10000 | 573 | 2.47×10-5 | 0.15 |

| MM-16K | 20 | 0.6 | 3 | +1.2 | 9000 | 1146 | 6.12×10-5 | 0.30 |

| MM-19K | 20 | 0.7 | 3 | +1.2 | 8000 | 1146 | 8.42×10-5 | 0.32 |

| MM-20K | 40 | 0.7 | 3 | +1.6 | 7000 | 2292 | 1.99×10-4 | 0.70 |

| MM-24K | 40 | 0.9 | 3 | +1.6 | 7000 | 2292 | 2.63×10-4 | 0.75 |

| MM-25K | 90 | 0.9 | 3 | +2.0 | 6000 | 3438 | 5.66×10-4 | 1.25 |

| MM-28K | 90 | 1.0 | 3 | +2.0 | 6000 | 2865 | 5.77×10-4 | 1.35 |

| MM-30K | 150 | 1.1 | 3 | +2.5 | 5000 | 4297.5 | 1.39×10-3 | 2.10 |

| MM-35K | 220 | 1.2 | 3 | +3.2 | 4500 | 6303 | 3.01×10-3 | 3.50 |

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 转动惯量[kg•m2] | 质量[kg] | ||

|---|---|---|---|---|---|---|---|---|

| 偏心[mm] | 偏角[°] | 轴向[mm] | ||||||

| MM-6K-S | 2.5 | 0.3 | 3 | +0.6 | 20000 | 143 | 7.65×10-7 | 0.03 |

| MM-8K-S | 5 | 0.3 | 3 | +0.8 | 15000 | 286.5 | 4.08×10-6 | 0.07 |

| MM-12K-S | 10 | 0.4 | 3 | +1.0 | 12000 | 573 | 1.43×10-5 | 0.14 |

| MM-16K-S | 20 | 0.6 | 3 | +1.2 | 9000 | 1146 | 6.12×10-5 | 0.30 |

| MM-20K-S | 40 | 0.7 | 3 | +1.6 | 7000 | 2292 | 1.99×10-4 | 0.70 |

| MM-25K-S | 90 | 0.9 | 3 | +2.0 | 6000 | 3438 | 5.66×10-4 | 1.25 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

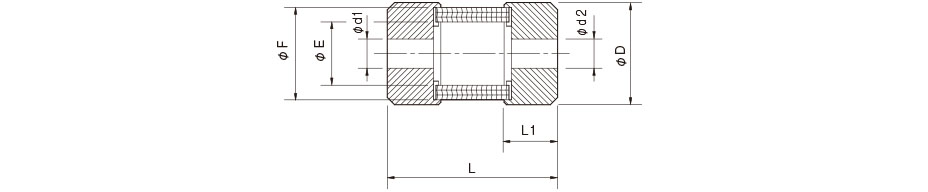

【尺寸】

| 型号 | d1, d2 | D | L | L1 | E | F | ||

|---|---|---|---|---|---|---|---|---|

| 底孔 | 最小 | 最大 | ||||||

| MM-6K | 2.5 | 3 | 8 | 16 | 20 | 6 | 11 | 15.5 |

| MM-8K | 3.5 | 4 | 8 | 21 | 35 | 11 | 13 | 19 |

| MM-12K | 5.5 | 6 | 12 | 26 | 50 | 16.5 | 16.5 | 24 |

| MM-14K | 5.5 | 7 | 14 | 30 | 50 | 16.5 | 20.5 | 28 |

| MM-16K | 5.5 | 10 | 16 | 35 | 65 | 22 | 22.4 | 32 |

| MM-19K | 5.5 | 10 | 19 | 38 | 65 | 22 | 26.4 | 36 |

| MM-20K | 5.5 | 10 | 20 | 45 | 80 | 27 | 28 | 40 |

| MM-24K | 5.5 | 14 | 24 | 48 | 80 | 27 | 33 | 45 |

| MM-25K | 5.5 | 14 | 25 | 55 | 100 | 33.5 | 35 | 50 |

| MM-28K | 5.5 | 14 | 28 | 55 | 100 | 33.5 | 37 | 52 |

| MM-30K | 5.5 | 16 | 30 | 65 | 125 | 40 | 40.8 | 60 |

| MM-35K | 5.5 | 20 | 35 | 75 | 150 | 48 | 46 | 70 |

| 型号 | d1, d2 | D | L | L1 | E | F | ||

|---|---|---|---|---|---|---|---|---|

| 底孔 | 最小 | 最大 | ||||||

| MM-6K-S | 2.5 | 3 | 8 | 17 | 25 | 9 | 11 | 15.5 |

| MM-8K-S | 3.5 | 4 | 8 | 21 | 35 | 11 | 13 | 19 |

| MM-12K-S | 5.5 | 6 | 12 | 26 | 50 | 16.5 | 16.5 | 24 |

| MM-16K-S | 5.5 | 10 | 16 | 35 | 65 | 22 | 22.4 | 32 |

| MM-20K-S | 5.5 | 10 | 20 | 45 | 80 | 27 | 28 | 40 |

| MM-25K-S | 5.5 | 14 | 25 | 55 | 100 | 32.5 | 35 | 50 |

※底孔为钻孔。

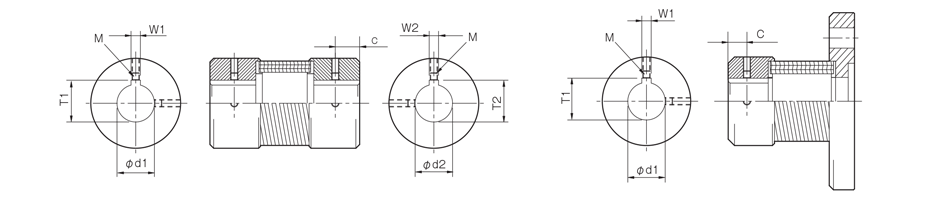

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | 支持电动机标准 JIS C 4210 2001 | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差E9 | - | 公差H7 | 公差H9 | - | 公差H7 | 公差JS9 | - | 公差G7,F7 | 公差H9 | - | ||||||||

| 4 | 4+0.0180 | - | - | 2-M3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 5 | 5+0.0180 | - | - | 2-M3 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 6 | 6+0.0180 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 7 | 7+0.0220 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 8 | 8+0.0220 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 9 | 9+0.0220 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 10 | 10+0.0220 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 11 | 11+0.0180 | - | - | 2-M4 | - | - | - | - | - | - | - | - | - | - | - | - | - | - | - |

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14 | 14+0.0180 | 5+0.050+0.020 | 16.0+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15 | 15+0.0180 | 5+0.050+0.020 | 17.0+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16 | 16+0.0180 | 5+0.050+0.020 | 18.0+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17 | 17+0.0180 | 5+0.050+0.020 | 19.0+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18 | 18+0.0180 | 5+0.050+0.020 | 20.0+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19 | 19+0.0210 | 5+0.050+0.020 | 21.0+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20 | 20+0.0210 | 5+0.050+0.020 | 22.0+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22 | 22+0.0210 | 7+0.061+0.025 | 25.0+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24 | 24+0.0210 | 7+0.061+0.025 | 27.0+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25 | 25+0.0210 | 7+0.061+0.025 | 28.0+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28 | 28+0.0210 | 7+0.061+0.025 | 31.0+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30 | 30+0.0210 | 7+0.061+0.025 | 33.0+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | - | - | - | - | - |

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | - | - | - | - | - |

※此标准孔加工规格适用于BAUMANN FLEX MM 和MF 型。

※φ11 以下的标准与所有JIS 旧标准栏的内容相同。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 联轴器尺寸 | 从端面的位置C[ mm] |

|---|---|

| 6 | 3 |

| 8 | 5 |

| 12・14 | 7 |

| 16・19・20・24 | 10 |

| 25・28・30・35 | 15 |