![]()

- MIKI PULLEY TOP >

- Product Information >

- COUPLINGS >

- SERVOFLEX >

- SFC Models

Features of SFC Models

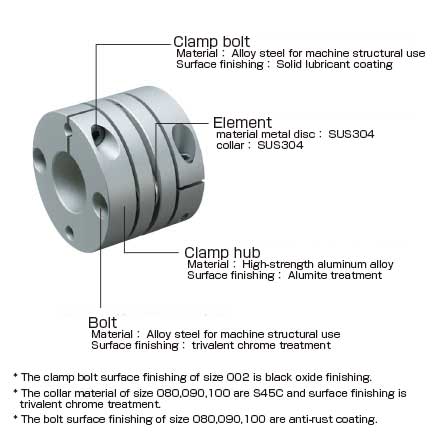

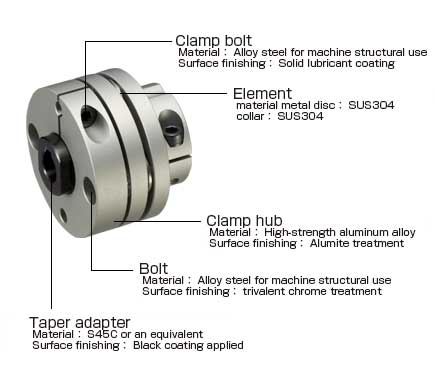

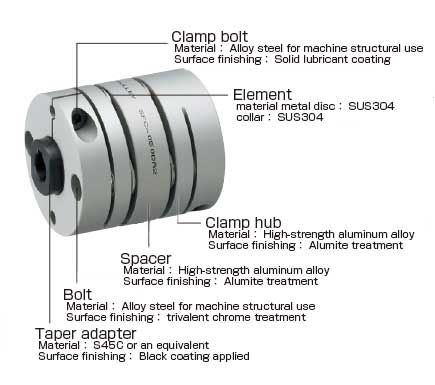

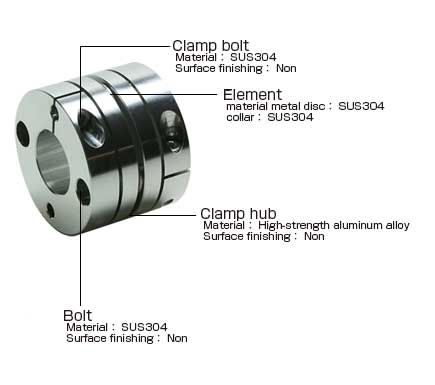

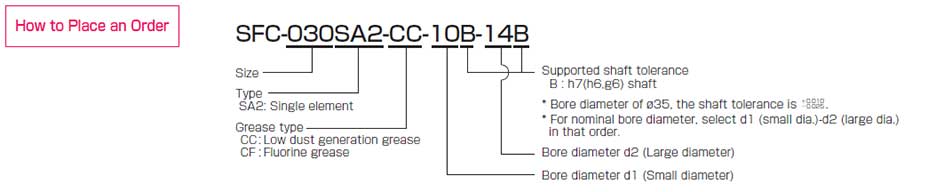

These are disc-spring couplings that use a lightweight, high-strength aluminum alloy for the clamp hub to enable high torsional stiffness and high response. Both single-element types with high torsional stiffness and flexible double-element types that separate double elements with a spacer are available. Both lower the moment of inertia by linking the outer diameter of the hub to the shaft diameter.

Ultra-low inertia

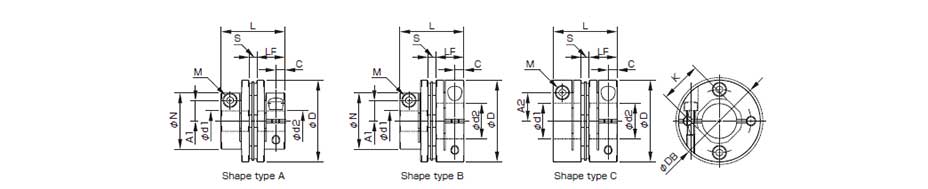

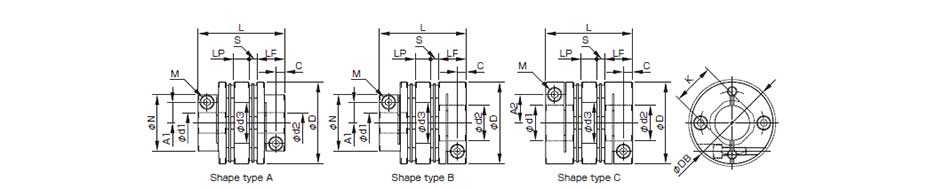

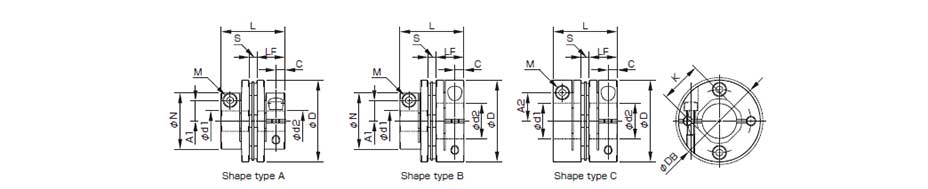

The outer diameter shape of the clamp hub is linked to the bore diameter you are using. This decreases inertia to the lowest amount necessary by reducing the outer diameter when the bore diameter is small, making these optimal for fast-accelerating operation. Three shapes are available to match the combination of bore diameters you are using.

Simple, reliable, no backlash

Since the clamp method is used to couple to the shaft, mounting can be completed by tightening one bolt each on left and right. Clamp hubs enable reliable connections that are strong against vibration and shocks, and all power is transmitted by frictional couplings, so there is no backlash. The clamp hubs on both sides of the coupling are centered using a dedicated tool, ensuring concentricity.

For tapered shafts

Allows coupling via a clamp hub when an optional taper adapter is mounted on the tapered shaft of a servo motor.

Custom-ordered specific lengths (SFC DA2 types)

This type allows you to specify a specific length that matches the distance between shafts that you require.

Clean room compatible

It is a clean room compatible product that has been cleaned, assembled (ISO class 6) and packed in consideration of its use in clean rooms.

SFC Models Specifications

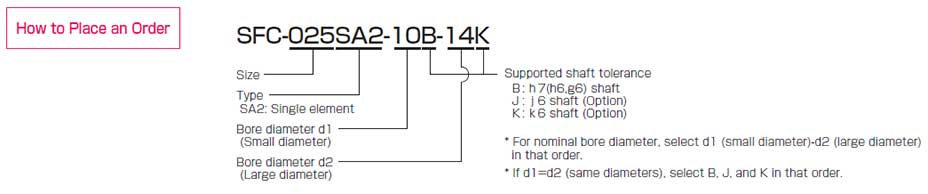

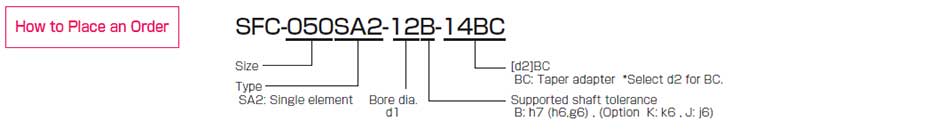

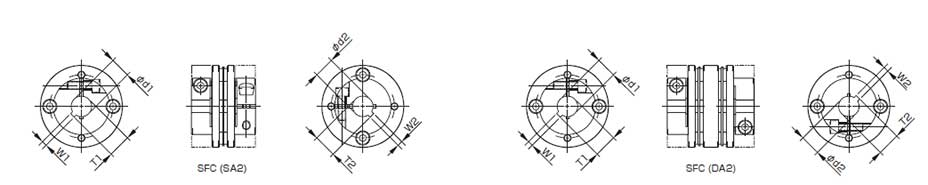

SFC-□SA2 Types

[Specifications]

| Model | Type | Rated torque [N・m] | Misalignment | Max. rotation speed [min-1] | Torsional stiffness [N・m/rad] | Axial stiffness [N/mm] | Moment of inertia [kg・m2] | Mass[kg] | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Parallel[mm] | Angular[゜] | Axial[mm] | ||||||||

| SFC-002SA2 | C | 0.25 | 0.01 | 0.5 | ±0.04 | 10000 | 190 | 34 | 0.06×10-6 | 0.003 |

| SFC-005SA2 | C | 0.6 | 0.02 | 0.5 | ±0.05 | 10000 | 500 | 140 | 0.26×10-6 | 0.007 |

| SFC-010SA2 | C | 1 | 0.02 | 1 | ±0.1 | 10000 | 1400 | 140 | 0.58×10-6 | 0.011 |

| SFC-020SA2 | C | 2 | 0.02 | 1 | ±0.15 | 10000 | 3700 | 64 | 2.39×10-6 | 0.025 |

| SFC-025SA2 | C | 4 | 0.02 | 1 | ±0.19 | 10000 | 5600 | 60 | 3.67×10-6 | 0.029 |

| SFC-030SA2 | A | 5 | 0.02 | 1 | ±0.2 | 10000 | 8000 | 64 | 4.07×10-6 | 0.034 |

| B | 6.09×10-6 | 0.041 | ||||||||

| C | 8.20×10-6 | 0.049 | ||||||||

| SFC-035SA2 | C | 10 | 0.02 | 1 | ±0.25 | 10000 | 18000 | 112 | 18.44×10-6 | 0.082 |

| SFC-040SA2 | A | 12 | 0.02 | 1 | ±0.3 | 10000 | 20000 | 80 | 16.71×10-6 | 0.077 |

| B | 22.55×10-6 | 0.085 | ||||||||

| C | 29.25×10-6 | 0.100 | ||||||||

| SFC-050SA2 | A | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 55.71×10-6 | 0.159 |

| B | 76.26×10-6 | 0.177 | ||||||||

| C | 99.03×10-6 | 0.206 | ||||||||

| SFC-055SA2 | C | 40 | 0.02 | 1 | ±0.42 | 10000 | 50000 | 43 | 188.0×10-6 | 0.314 |

| SFC-060SA2 | A | 60 | 0.02 | 1 | ±0.45 | 10000 | 70000 | 76.4 | 145.9×10-6 | 0.283 |

| B | 205.0×10-6 | 0.326 | ||||||||

| C | 268.6×10-6 | 0.385 | ||||||||

| SFC-080SA2 | C | 100 | 0.02 | 1 | ±0.55 | 10000 | 140000 | 128 | 710.6×10-6 | 0.708 |

| SFC-090SA2 | C | 180 | 0.02 | 1 | ±0.65 | 10000 | 100000 | 108 | 1236×10-6 | 0.946 |

| SFC-100SA2 | C | 250 | 0.02 | 1 | ±0.74 | 10000 | 120000 | 111 | 1891×10-6 | 1.202 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* Check the Standard Bore Diameter list as rated torque may be restricted by the holding power of the shaft connection component.

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | Type | d1[mm] | d2[mm] | D[mm] | DB[mm] | N[mm] | L[mm] | LF[mm] | S[mm] | A1[mm] | A2[mm] | C[mm] | K[mm] | M Qty - Nominal dia | Tightening torque[N・m] | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | ||||||||||||||

| SFC-002SA2 | C | 3 | 5 | 3 | 5 | 12 | 12.4 | ─ | 12.35 | 5.9 | 0.55 | ─ | 3.7 | 1.9 | 5.6 | 1-M1.6 | 0.23 to 0.28 |

| SFC-005SA2 | C | 3 | 6 | 3 | 6 | 16 | ─ | ─ | 16.7 | 7.85 | 1 | ─ | 4.8 | 2.5 | 6.5 | 1-M2 | 0.4 to 0.5 |

| SFC-010SA2 | C | 3 | 8 | 3 | 8 | 19 | ─ | ─ | 19.35 | 9.15 | 1.05 | ─ | 5.8(6) | 3.15 | 8.5 | 1-M2.5(M2) | 1.0 to 1.1(0.4 to 0.5) |

| SFC-020SA2 | C | 4 | 10 | 4 | 11 | 26 | ─ | ─ | 23.15 | 10.75 | 1.65 | ─ | 9.5 | 3.3 | 10.6 | 1-M2.5 | 1.0 to 1.1 |

| SFC-025SA2 | C | 5 | 14 | 5 | 14 | 29 | ─ | ─ | 23.4 | 10.75 | 1.9 | ─ | 11 | 3.3 | 14.5 | 1-M2.5 | 1.0 to 1.1 |

| SFC-030SA2 | A | 5 | 10 | 5 | 10 | 34 | ─ | 21.6 | 27.3 | 12.4 | 2.5 | 8 | ─ | 3.75 | 14.5 | 1-M3 | 1.5 to 1.9 |

| B | 5 | 10 | Over 10 | 16 | 8 | 12.5 | |||||||||||

| C | Over 10 | 14 | Over 10 | 16 | ─ | ─ | 12.5 | ||||||||||

| SFC-035SA2 | C | 6 | 16 | 6 | 19 | 39 | ─ | ─ | 34 | 15.5 | 3 | ─ | 14 | 4.5 | 17 | 1-M4 | 3.4 to 4.1 |

| SFC-040SA2 | A | 8 | 15 | 8 | 15 | 44 | ─ | 29.6 | 34 | 15.5 | 3 | 11 | ─ | 4.5 | 19.5 | 1-M4 | 3.4 to 4.1 |

| B | 8 | 15 | Over 15 | 24 | 11 | 17 | |||||||||||

| C | Over 15 | 19 | Over 15 | 24 | ─ | ─ | 17 | ||||||||||

| SFC-050SA2 | A | 8 | 19 | 8 | 19 | 56 | ─ | 38 | 43.4 | 20.5 | 2.4 | 14.5 | ─ | 6 | 26 | 1-M5 | 7.0 to 8.5 |

| B | 8 | 19 | Over 19 | 30 | 14.5 | 22 | |||||||||||

| C | Over 19 | 25 | Over 19 | 30 | ─ | ─ | 22 | ||||||||||

| SFC-055SA2 | C | 10 | 30 | 10 | 30 | 63 | ─ | ─ | 50.6 | 24 | 2.6 | ─ | 23 | 7.75 | 31 | 1-M6 | 14 to 15 |

| SFC-060SA2 | A | 11 | 24 | 11 | 24 | 68 | ─ | 46 | 53.6 | 25.2 | 3.2 | 17.5 | ─ | 7.75 | 31 | 1-M6 | 14 to 15 |

| B | 11 | 24 | Over 24 | 35 | 17.5 | 26.5 | |||||||||||

| C | Over 24 | 30 | Over 24 | 35 | ─ | ─ | 26.5 | ||||||||||

| SFC-080SA2 | C | 18 | 35 | 18 | 40 | 82 | ─ | ─ | 68 | 30 | 8 | ─ | 28 | 9 | 38 | 1-M8 | 27 to 30 |

| SFC-090SA2 | C | 25 | 40 | 25 | 45 | 94 | ─ | ─ | 68.3 | 30 | 8.3 | ─ | 34 | 9 | 42 | 1-M8 | 27 to 30 |

| SFC-100SA2 | C | 32 | 45 | 32 | 45 | 104 | ─ | ─ | 69.8 | 30 | 9.8 | ─ | 39 | 9 | 48 | 1-M8 | 27 to 30 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* The øDB value is measured assuming that the head of the clamping bolt is larger than the external diameter of the hub.

* The K dimension is the inner diameter of the element. For d2 dimension exceeding this value, shaft can be inserted only up to LF dimension to the d2 side hub.

* The nominal diameter for the clamping bolt M is equal to the quantity minus the nominal diameter of the screw threads, where the quantity is for a hub on one side.

* The figures in parentheses ( ) for the SFC-010 are the values when d1 or d2 is ø8 mm.

[Standard bore diameter]

| Standard (option) bore diameter, d1/d2 [mm] and restricted rated torque [N∙m] | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore diameter | 3 | 4 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | |

| Shaft tolerance h7 (h6・g6) | B | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Shaft tolerance j6 (Option) | J | ○ | ○ | ○ | ○ | |||||||||||||||||||||||||||

| Shaft tolerance k6 (Option) | K | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||||||||

| SFC-002SA2 | d1 | ● | ● | ● | ||||||||||||||||||||||||||||

| d2 | ● | ● | ● | |||||||||||||||||||||||||||||

| SFC-005SA2 | d1 | ● | ● | ● | ● | |||||||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ||||||||||||||||||||||||||||

| SFC-010SA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||||

| SFC-020SA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||

| SFC-025SA2 | d1 | 2.1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 2.1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||

| SFC-030SA2 | d1 | 2.8 | 3.4 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 2.8 | 3.4 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| SFC-035SA2 | d1 | 5 | 5 | 6.6 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| d2 | 5 | 5 | 6.6 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-040SA2 | d1 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| d2 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-050SA2 | d1 | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFC-055SA2 | d1 | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-060SA2 | d1 | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| d2 | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| SFC-080SA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||

| SFC-090SA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||

| SFC-100SA2 | d1 | 226 | ● | ● | ● | ● | ● | |||||||||||||||||||||||||

| d2 | 226 | ● | ● | ● | ● | ● | ||||||||||||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is - 0.025 to +0.010.

* Shaft tolerances j6/k6: designations J/K are optional, and are only supported for bore diameters marked with ○ .

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N•m].

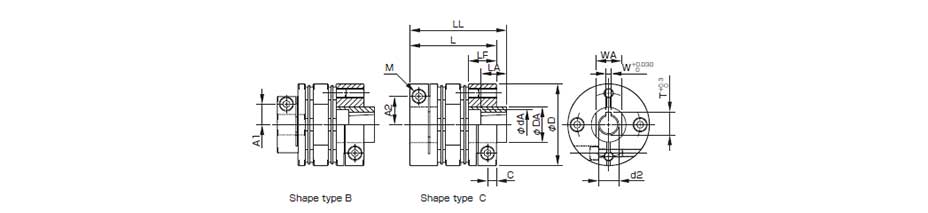

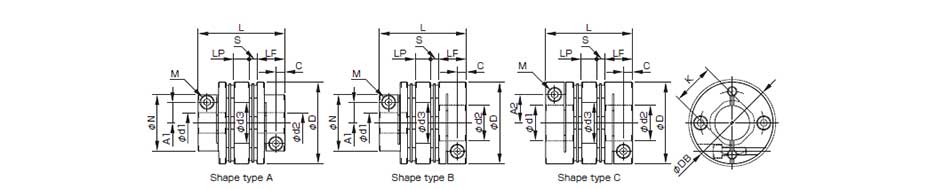

SFC-□DA2 Types

[Specifications]

| Model | Type | Rated torque [N・m] | Misalignment | Max. rotation speed [min-1] | Torsional stiffness [N・m/rad] | Axial stiffness [N/mm] | Moment of inertia [kg・m2] | Mass[kg] | ||

|---|---|---|---|---|---|---|---|---|---|---|

| Parallel[mm] | Angular[゜] | Axial[mm] | ||||||||

| SFC-002DA2 | C | 0.25 | 0.03 | 0.5(On one side) | ±0.08 | 10000 | 95 | 17 | 0.07×10-6 | 0.004 |

| SFC-005DA2 | C | 0.6 | 0.05 | 0.5(On one side) | ±0.1 | 10000 | 250 | 70 | 0.37×10-6 | 0.010 |

| SFC-010DA2 | C | 1 | 0.11 | 1(On one side) | ±0.2 | 10000 | 700 | 70 | 0.80×10-6 | 0.015 |

| SFC-020DA2 | C | 2 | 0.15 | 1(On one side) | ±0.33 | 10000 | 1850 | 32 | 3.43×10-6 | 0.035 |

| SFC-025DA2 | C | 4 | 0.16 | 1(On one side) | ±0.38 | 10000 | 2800 | 30 | 5.26×10-6 | 0.040 |

| SFC-030DA2 | A | 5 | 0.18 | 1(On one side) | ±0.4 | 10000 | 4000 | 32 | 7.43×10-6 | 0.054 |

| B | 9.45×10-6 | 0.060 | ||||||||

| C | 11.56×10-6 | 0.068 | ||||||||

| SFC-035DA2 | C | 10 | 0.24 | 1(On one side) | ±0.5 | 10000 | 9000 | 56 | 26.93×10-6 | 0.121 |

| SFC-040DA2 | A | 12 | 0.24 | 1(On one side) | ±0.6 | 10000 | 10000 | 40 | 29.98×10-6 | 0.124 |

| B | 35.82×10-6 | 0.131 | ||||||||

| C | 42.52×10-6 | 0.146 | ||||||||

| SFC-050DA2 | A | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 98.34×10-6 | 0.250 |

| B | 118.9×10-6 | 0.268 | ||||||||

| C | 141.7×10-6 | 0.298 | ||||||||

| SFC-055DA2 | C | 40 | 0.31 | 1(On one side) | ±0.84 | 10000 | 25000 | 21.5 | 261.3×10-6 | 0.459 |

| SFC-060DA2 | A | 60 | 0.34 | 1(On one side) | ±0.9 | 10000 | 35000 | 38.2 | 256.6×10-6 | 0.447 |

| B | 315.7×10-6 | 0.489 | ||||||||

| C | 379.3×10-6 | 0.549 | ||||||||

| SFC-080DA2 | C | 100 | 0.52 | 1(On one side) | ±1.10 | 10000 | 70000 | 64 | 1039×10-6 | 1.037 |

| SFC-090DA2 | C | 180 | 0.52 | 1(On one side) | ±1.30 | 10000 | 50000 | 54 | 1798×10-6 | 1.369 |

| SFC-100DA2 | C | 250 | 0.55 | 1(On one side) | ±1.48 | 10000 | 60000 | 55.5 | 2754×10-6 | 1.739 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* Check the "Standard Bore Diameters" as rated torque may be restricted by the holding power of the shaft connection component.

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | Type | d1[mm] | d2[mm] | D[mm] | DB[mm] | N[mm] | L[mm] | LF[mm] | LP[mm] | S[mm] | A1[mm] | A2[mm] | C[mm] | d3[mm] | K[mm] | M Qty - Nominal dia | Tightening torque[N・m] | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | ||||||||||||||||

| SFC-002DA2 | C | 3 | 5 | 3 | 5 | 12 | 12.4 | ─ | 15.7 | 5.9 | 2.8 | 0.55 | ─ | 3.7 | 1.9 | 5.2 | 5.6 | 1-M1.6 | 0.23 to 0.28 |

| SFC-005DA2 | C | 3 | 6 | 3 | 6 | 16 | ─ | ─ | 23.2 | 7.85 | 5.5 | 1 | ─ | 4.8 | 2.5 | 6.5 | 6.5 | 1-M2 | 0.4 to 0.5 |

| SFC-010DA2 | C | 3 | 8 | 3 | 8 | 19 | ─ | ─ | 25.9 | 9.15 | 5.5 | 1.05 | ─ | 5.8(6) | 3.15 | 8.5 | 8.5 | 1-M2.5(M2) | 1.0 to 1.1(0.4 to 0.5) |

| SFC-020DA2 | C | 4 | 10 | 4 | 11 | 26 | ─ | ─ | 32.3 | 10.75 | 7.5 | 1.65 | ─ | 9.5 | 3.3 | 10.6 | 10.6 | 1-M2.5 | 1.0 to 1.1 |

| SFC-025DA2 | C | 5 | 14 | 5 | 14 | 29 | ─ | ─ | 32.8 | 10.75 | 7.5 | 1.9 | ─ | 11 | 3.3 | 15 | 14.5 | 1-M2.5 | 1.0 to 1.1 |

| SFC-030DA2 | A | 5 | 10 | 5 | 10 | 34 | ─ | 21.6 | 37.8 | 12.4 | 8 | 2.5 | 8 | ─ | 3.75 | 15 | 14.5 | 1-M3 | 1.5 to 1.9 |

| B | 5 | 10 | Over 10 | 16 | 8 | 12.5 | |||||||||||||

| C | Over 10 | 14 | Over 10 | 16 | ─ | ─ | 12.5 | ||||||||||||

| SFC-035DA2 | C | 6 | 16 | 6 | 19 | 39 | ─ | ─ | 48 | 15.5 | 11 | 3 | ─ | 14 | 4.5 | 17 | 17 | 1-M4 | 3.4 to 4.1 |

| SFC-040DA2 | A | 8 | 15 | 8 | 15 | 44 | ─ | 29.6 | 48 | 15.5 | 11 | 3 | 11 | ─ | 4.5 | 20 | 19.5 | 1-M4 | 3.4 to 4.1 |

| B | 8 | 15 | Over 15 | 24 | 11 | 17 | |||||||||||||

| C | Over 15 | 19 | Over 15 | 24 | ─ | ─ | 17 | ||||||||||||

| SFC-050DA2 | A | 8 | 19 | 8 | 19 | 56 | ─ | 38 | 59.8 | 20.5 | 14 | 2.4 | 14.5 | ─ | 6 | 26 | 26 | 1-M5 | 7.0 to 8.5 |

| B | 8 | 19 | Over 19 | 30 | 14.5 | 22 | |||||||||||||

| C | Over 19 | 25 | Over 19 | 30 | ─ | ─ | 22 | ||||||||||||

| SFC-055DA2 | C | 10 | 30 | 10 | 30 | 63 | ─ | ─ | 68.7 | 24 | 15.5 | 2.6 | ─ | 23 | 7.75 | 31 | 31 | 1-M6 | 14 to 15 |

| SFC-060DA2 | A | 11 | 24 | 11 | 24 | 68 | ─ | 46 | 73.3 | 25.2 | 16.5 | 3.2 | 17.5 | ─ | 7.75 | 31 | 31 | 1-M6 | 14 to 15 |

| B | 11 | 24 | Over 24 | 35 | 17.5 | 26.5 | |||||||||||||

| C | Over 24 | 30 | Over 24 | 35 | ─ | ─ | 26.5 | ||||||||||||

| SFC-080DA2 | C | 18 | 35 | 18 | 40 | 82 | ─ | ─ | 98 | 30 | 22 | 8 | ─ | 28 | 9 | 40 | 38 | 1-M8 | 27 to 30 |

| SFC-090DA2 | C | 25 | 40 | 25 | 45 | 94 | ─ | ─ | 98.6 | 30 | 22 | 8.3 | ─ | 34 | 9 | 47 | 42 | 1-M8 | 27 to 30 |

| SFC-100DA2 | C | 32 | 45 | 32 | 45 | 104 | ─ | ─ | 101.6 | 30 | 22 | 9.8 | ─ | 39 | 9 | 50 | 48 | 1-M8 | 27 to 30 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* The øDB value is measured assuming that the head of the clamping bolt is larger than the external diameter of the hub.

* The K dimension is the inner diameter of the element. For d2 dimension exceeding this value, shaft can be inserted only up to LF dimension to the d2 side hub.

* The nominal diameter for the clamping bolt M is equal to the quantity minus the nominal diameter of the screw threads, where the quantity is for a hub on one side.

* The figures in parentheses ( ) for the SFC-010 are the values when d1 or d2 is ø8 mm.

[Standard bore diameter]

| Standard (option) bore diameter, d1/d2 [mm] and restricted rated torque [N∙m] | ||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore diameter | 3 | 4 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | |

| Shaft tolerance h7 (h6・g6) | B | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Shaft tolerance j6 (Option) | J | ○ | ○ | ○ | ○ | |||||||||||||||||||||||||||

| Shaft tolerance k6 (Option) | K | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||||||||

| SFC-002DA2 | d1 | ● | ● | ● | ||||||||||||||||||||||||||||

| d2 | ● | ● | ● | |||||||||||||||||||||||||||||

| SFC-005DA2 | d1 | ● | ● | ● | ● | |||||||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ||||||||||||||||||||||||||||

| SFC-010DA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||||

| SFC-020DA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||

| SFC-025DA2 | d1 | 2.1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 2.1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||

| SFC-030DA2 | d1 | 2.8 | 3.4 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 2.8 | 3.4 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| SFC-035DA2 | d1 | 5 | 5 | 6.6 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| d2 | 5 | 5 | 6.6 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-040DA2 | d1 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| d2 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-050DA2 | d1 | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFC-055DA2 | d1 | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-060DA2 | d1 | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| d2 | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| SFC-080DA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||

| SFC-090DA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||||||||

| SFC-100DA2 | d1 | 226 | ● | ● | ● | ● | ● | |||||||||||||||||||||||||

| d2 | 226 | ● | ● | ● | ● | ● | ||||||||||||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is - 0.025 to +0.010.

* Shaft tolerances j6/k6: designations J/K are optional, and are only supported for bore diameters marked with ○ .

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N•m].

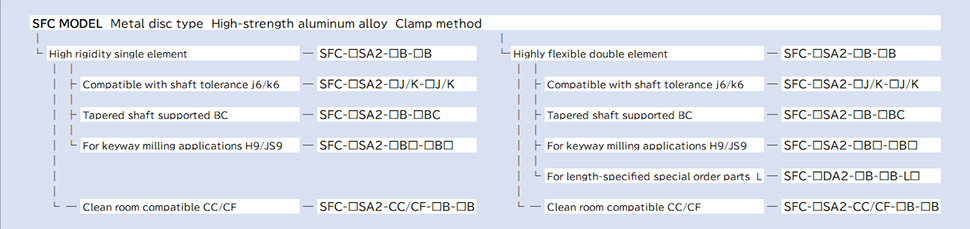

Lineup

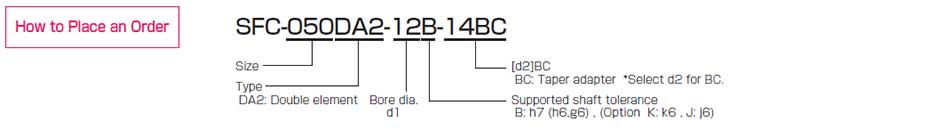

Options of SFC Models

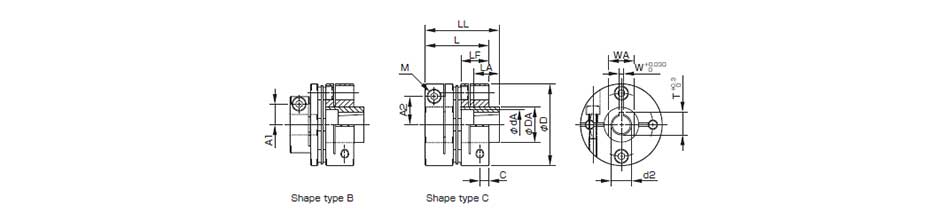

Tapered shaft supportedAllows coupling clamping hub when a taper adapter is mounted on the tapered shaft of a servo motor.

SFC-□SA2(BC)

[Specifications]

| Model | shape TYPE | Rated torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg・m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] |

Angular [°] |

Axial [mm] |

||||||||

| SFC-040SA2-□B-11BC | B | 12 | 0.02 | 1 | ±0.3 | 10000 | 20000 | 80 | 26.58×10-6 | 0.131 |

| C | 12 | 0.02 | 1 | ±0.3 | 10000 | 20000 | 80 | 33.28×10-6 | 0.146 | |

| SFC-050SA2-□B-11BC | B | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 82.91×10-6 | 0.240 |

| C | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 103.5×10-6 | 0.258 | |

| SFC-050SA2-□B-14BC | B | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 88.72×10-6 | 0.271 |

| C | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 111.5×10-6 | 0.301 | |

| SFC-050SA2-□B-16BC | B | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 95.44×10-6 | 0.309 |

| C | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 118.2×10-6 | 0.338 | |

| SFC-055SA2-□B-14BC | C | 40 | 0.02 | 1 | ±0.42 | 10000 | 50000 | 43 | 201.1×10-6 | 0.409 |

| SFC-055SA2-□B-16BC | C | 40 | 0.02 | 1 | ±0.42 | 10000 | 50000 | 43 | 207.8×10-6 | 0.446 |

| SFC-060SA2-□B-16BC | B | 60 | 0.02 | 1 | ±0.45 | 10000 | 70000 | 76.4 | 228.7×10-6 | 0.475 |

| C | 60 | 0.02 | 1 | ±0.45 | 10000 | 70000 | 76.4 | 287.8×10-6 | 0.517 | |

* Types B / C are automatically specified by Miki Pulley according to the bore diameter you select, and cannot be specified by the customer.

* Check the "Standard Bore Diameters" as rated torque may be restricted by the holding power of the shaft connection component.

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | d2 | W | T | WA | LA | dA | DA | LL | D | L | LF | C | A1 | A2 | M Qty - Nominal dia. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFC-040SA2-□B-11BC | 11 | 4 | 12.2 | 18 | 16 | 17 | 22 | 44 | 44 | 34 | 15.5 | 4.5 | 11 | 17 | 1-M4 |

| SFC-050SA2-□B-11BC | 11 | 4 | 12.2 | 18 | 16 | 17 | 22 | 48.4 | 56 | 43.4 | 20.5 | 6 | 14.5 | 22 | 1-M5 |

| SFC-050SA2-□B-14BC | 14 | 4 | 15.1 | 24 | 19 | 22 | 28 | 53.4 | 56 | 43.4 | 20.5 | 6 | 14.5 | 22 | 1-M5 |

| SFC-050SA2-□B-16BC | 16 | 5 | 17.3 | 24 | 29 | 26 | 30 | 63.4 | 56 | 43.4 | 20.5 | 6 | 14.5 | 22 | 1-M5 |

| SFC-055SA2-□B-14BC | 14 | 4 | 15.1 | 24 | 19 | 22 | 28 | 56.6 | 63 | 50.6 | 24 | 7.75 | - | 23 | 1-M6 |

| SFC-055SA2-□B-16BC | 16 | 5 | 17.3 | 24 | 29 | 26 | 30 | 66.6 | 63 | 50.6 | 24 | 7.75 | - | 23 | 1-M6 |

| SFC-060SA2-□B-16BC | 16 | 5 | 17.3 | 24 | 29 | 26 | 30 | 69.6 | 68 | 53.6 | 25.2 | 7.75 | 17.5 | 26.5 | 1-M6 |

* For other dimensions, see dimensions for single element type SFC-□SA2.

[Standard bore diameter]

| Standard (option) bore diameter, d1 [mm] and restricted rated torque [N・m] | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore diameter | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | |

| Shaft tolerance h7(h6,g6) | B | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Shaft tolerance j6(option) | J | ○ | ○ | ○ | ○ | |||||||||||||||||

| Shaft tolerance k6(option) | K | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||||

| SFC-040SA2-□B-11BC | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-050SA2-□B-11BC | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| SFC-050SA2-□B-14BC | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| SFC-050SA2-□B-16BC | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| SFC-055SA2-□B-14BC | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| SFC-055SA2-□B-16BC | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| SFC-060SA2-□B-16BC | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Shaft tolerances j6/k6: designations J/K are optional, and are only supported for bore diameters marked with ○ .

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

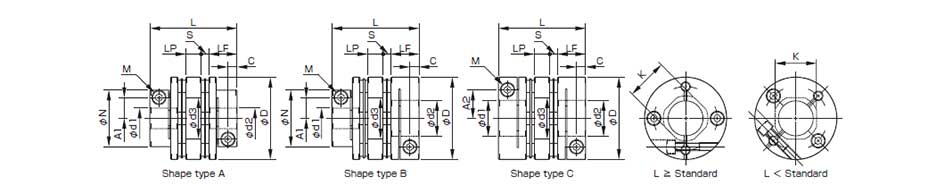

SFC-□DA2(BC)

[Specifications]

| Model | shape TYPE | Rated torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg・m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] |

Angular [°] |

Axial [mm] |

||||||||

| SFC-040DA2-□B-11BC | B | 12 | 0.24 | 1(On one side) | ±0.6 | 10000 | 10000 | 40 | 39.42×10-6 | 0.180 |

| C | 12 | 0.24 | 1(On one side) | ±0.6 | 10000 | 10000 | 40 | 46.12×10-6 | 0.195 | |

| SFC-050DA2-□B-11BC | B | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 125.5×10-6 | 0.331 |

| C | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 146.1×10-6 | 0.349 | |

| SFC-050DA2-□B-14BC | B | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 131.1×10-6 | 0.362 |

| C | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 154.1×10-6 | 0.392 | |

| SFC-050DA2-□B-16BC | B | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 138.1×10-6 | 0.400 |

| C | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 160.8×10-6 | 0.430 | |

| SFC-055DA2-□B-14BC | C | 40 | 0.31 | 1(On one side) | ±0.84 | 10000 | 25000 | 21.5 | 274.0×10-6 | 0.530 |

| SFC-055DA2-□B-16BC | C | 40 | 0.31 | 1(On one side) | ±0.84 | 10000 | 25000 | 21.5 | 280.5×10-6 | 0.567 |

| SFC-060DA2-□B-16BC | B | 60 | 0.34 | 1(On one side) | ±0.9 | 10000 | 35000 | 38.2 | 339.4×10-6 | 0.638 |

| C | 60 | 0.34 | 1(On one side) | ±0.9 | 10000 | 35000 | 38.2 | 398.5×10-6 | 0.681 | |

* Types B / C are automatically specified by Miki Pulley according to the bore diameter you select, and cannot be specified by the customer.

* Check the "Standard Bore Diameters" as rated torque may be restricted by the holding power of the shaft connection component.

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | d2 | W | T | WA | LA | dA | DA | LL | D | L | LF | C | A1 | A2 | M Quantity - Nominal dia. |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFC-040DA2-□B-11BC | 11 | 4 | 12.2 | 18 | 16 | 17 | 22 | 58 | 44 | 48 | 15.5 | 4.5 | 11 | 17 | 1-M4 |

| SFC-050DA2-□B-11BC | 11 | 4 | 12.2 | 18 | 16 | 17 | 22 | 64.8 | 56 | 59.8 | 20.5 | 6 | 14.5 | 22 | 1-M5 |

| SFC-050DA2-□B-14BC | 14 | 4 | 15.1 | 24 | 19 | 22 | 28 | 69.8 | 56 | 59.8 | 20.5 | 6 | 14.5 | 22 | 1-M5 |

| SFC-050DA2-□B-16BC | 16 | 5 | 17.3 | 24 | 29 | 26 | 30 | 79.8 | 56 | 59.8 | 20.5 | 6 | 14.5 | 22 | 1-M5 |

| SFC-055DA2-□B-14BC | 14 | 4 | 15.1 | 24 | 19 | 22 | 28 | 74.4 | 63 | 68.7 | 24 | 7.75 | ― | 23 | 1-M6 |

| SFC-055DA2-□B-16BC | 16 | 5 | 17.3 | 24 | 29 | 26 | 30 | 84.7 | 63 | 68.7 | 24 | 7.75 | ― | 23 | 1-M6 |

| SFC-060DA2-□B-16BC | 16 | 5 | 17.3 | 24 | 29 | 26 | 30 | 89.3 | 68 | 73.3 | 25.2 | 7.75 | 17.5 | 26.5 | 1-M6 |

* For other dimensions, see dimensions for double element type SFC-□DA2.

[Standard bore diameter]

| Standard (option) bore diameter, d1 [mm] and restricted rated torque [N・m] | ||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore diameter | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | |

| Shaft tolerance h7(h6,g6) | B | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Shaft tolerance j6(option) | J | ○ | ○ | ○ | ○ | |||||||||||||||||

| Shaft tolerance k6(option) | K | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | |||||||||||||

| SFC-040DA2-□B-11BC | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-050DA2-□B-11BC | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||

| SFC-050DA2-□B-14BC | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| SFC-050DA2-□B-16BC | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

| SFC-055DA2-□B-14BC | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| SFC-055DA2-□B-16BC | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||

| SFC-060DA2-□B-16BC | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Shaft tolerances j6/k6: designations J/K are optional, and are only supported for bore diameters marked with ○ .

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

For length-specified special order partsSFC-□DA2 type spacer length can be changed to attain the necessary distance between shafts. Specify the length in 1 mm units.

SFC-□DA2(L)

[Specifications]

| Model | shape TYPE | Rated torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Moment of inertia [kg・m2] |

Mass [kg] |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Parallel[mm] | Angular [°] |

Axial [mm] |

|||||||||

| LMin. | LMax. | LMin. | LMax. | LMin. | LMax. | ||||||

| SFC-005DA2 | C | 0.6 | 0.03 | 0.20 | 0.5(On one side) | ±0.1 | 10000 | 0.33×10-6 | 0.62×10-6 | 0.009 | 0.017 |

| SFC-010DA2 | C | 1 | 0.08 | 0.44 | 1(On one side) | ±0.2 | 10000 | 0.72×10-6 | 1.38×10-6 | 0.014 | 0.026 |

| SFC-020DA2 | C | 2 | 0.10 | 0.46 | 1(On one side) | ±0.33 | 10000 | 3.02×10-6 | 5.30×10-6 | 0.031 | 0.054 |

| SFC-025DA2 | C | 4 | 0.09 | 0.46 | 1(On one side) | ±0.38 | 10000 | 4.55×10-6 | 7.95×10-6 | 0.036 | 0.061 |

| SFC-030DA2 | A | 5 | 0.11 | 0.48 | 1(On one side) | ±0.4 | 10000 | 6.09×10-6 | 12.80×10-6 | 0.046 | 0.085 |

| B | 8.11×10-6 | 14.82×10-6 | 0.053 | 0.091 | |||||||

| C | 10.22×10-6 | 16.93×10-6 | 0.061 | 0.099 | |||||||

| SFC-035DA2 | C | 10 | 0.15 | 0.54 | 1(On one side) | ±0.5 | 10000 | 23.85×10-6 | 35.97×10-6 | 0.108 | 0.161 |

| SFC-040DA2 | A | 12 | 0.15 | 0.54 | 1(On one side) | ±0.6 | 10000 | 25.06×10-6 | 44.76×10-6 | 0.107 | 0.174 |

| B | 30.89×10-6 | 50.62×10-6 | 0.116 | 0.182 | |||||||

| C | 37.58×10-6 | 57.31×10-6 | 0.130 | 0.197 | |||||||

| SFC-050DA2 | A | 25 | 0.16 | 0.63 | 1(On one side) | ±0.8 | 10000 | 77.42×10-6 | 144.3×10-6 | 0.205 | 0.347 |

| B | 97.97×10-6 | 164.8×10-6 | 0.225 | 0.365 | |||||||

| C | 120.8×10-6 | 187.6×10-6 | 0.252 | 0.394 | |||||||

| SFC-055DA2 | C | 40 | 0.16 | 0.60 | 1(On one side) | ±0.84 | 10000 | 226.8×10-6 | 325.0×10-6 | 0.378 | 0.538 |

| SFC-060DA2 | A | 60 | 0.19 | 0.63 | 1(On one side) | ±0.9 | 10000 | 210.8×10-6 | 340.1×10-6 | 0.382 | 0.567 |

| B | 269.9×10-6 | 399.2×10-6 | 0.424 | 0.609 | |||||||

| C | 333.5×10-6 | 462.8×10-6 | 0.484 | 0.669 | |||||||

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* Check the "Standard Bore Diameters" for SFC-□DA2 as there may be limitations on the rated torque caused by the holding power of the coupling shaft section.

* Max. rotation speed does not take into account dynamic balance.

* The moment of inertia and mass are measured for the maximum bore diameter.

* See "Specifications" for SFC-□DA2 for stiffness values.

[Dimensions]

| Model | shape TYPE | d1 | d2 | D | N | L | LF | S | A1 | A2 | C | d3 | K | M | Tightening torque [N・m] |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | Std. | Min. | Max. | |||||||||||||

| SFC-005DA2 | C | 3 | 6 | 3 | 6 | 16 | - | 23.2 | 21 | 40 | 7.85 | 1 | - | 4.8 | 2.5 | 6.5 | 6.5 | 1-M2 | 0.4 to 0.5 |

| SFC-010DA2 | C | 3 | 8 | 3 | 8 | 19 | - | 25.9 | 24 | 45 | 9.15 | 1.05 | - | 5.8(6) | 3.15 | 8.5 | 8.5 | 1-M2.5(M2) | 1.0 to 1.1(0.4 to 0.5) |

| SFC-020DA2 | C | 4 | 10 | 4 | 11 | 26 | - | 32.3 | 29 | 50 | 10.75 | 1.65 | - | 9.5 | 3.3 | 10.6 | 10.6 | 1-M2.5 | 1.0 to 1.1 |

| SFC-025DA2 | C | 5 | 14 | 5 | 14 | 29 | - | 32.8 | 29 | 50 | 10.75 | 1.9 | - | 11 | 3.3 | 15 | 14.5 | 1-M2.5 | 1.0 to 1.1 |

| SFC-030DA2 | A | 5 | 10 | 5 | 10 | 34 | 21.6 | 37.8 | 34 | 55 | 12.4 | 2.5 | 8 | - | 3.75 | 15 | 14.5 | 1-M3 | 1.5 to 1.9 |

| B | Over 10 | 16 | 12.5 | ||||||||||||||||

| C | Over 10 | 14 | - | - | |||||||||||||||

| SFC-035DA2 | C | 6 | 16 | 6 | 19 | 39 | - | 48 | 43 | 65 | 15.5 | 3 | - | 14 | 4.5 | 17 | 17 | 1-M4 | 3.4 to 4.1 |

| SFC-040DA2 | A | 8 | 15 | 8 | 15 | 44 | 29.6 | 48 | 43 | 65 | 15.5 | 3 | 11 | - | 4.5 | 20 | 19.5 | 1-M4 | 3.4 to 4.1 |

| B | Over 15 | 24 | 17 | ||||||||||||||||

| C | Over 15 | 19 | - | - | |||||||||||||||

| SFC-050DA2 | A | 8 | 19 | 8 | 19 | 56 | 38 | 59.8 | 53 | 80 | 20.5 | 2.4 | 14.5 | - | 6 | 26 | 26 | 1-M5 | 7.0 to 8.5 |

| B | Over 19 | 30 | 22 | ||||||||||||||||

| C | Over 19 | 25 | - | - | |||||||||||||||

| SFC-055DA2 | C | 10 | 30 | 10 | 30 | 63 | - | 68.7 | 60 | 85 | 24 | 2.6 | - | 23 | 7.75 | 31 | 31 | 1-M6 | 14 to 15 |

| SFC-060DA2 | A | 11 | 24 | 11 | 24 | 68 | 46 | 73.3 | 65 | 90 | 25.2 | 3.2 | 17.5 | - | 7.75 | 31 | 31 | 1-M6 | 14 to 15 |

| B | Over 24 | 35 | 26.5 | ||||||||||||||||

| C | Over 24 | 30 | - | - | |||||||||||||||

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* The nominal diameter for the clamping bolt M is equal to the quantity minus the nominal diameter of the screw threads, where the quantity is for a hub on one side.

* The figures in parentheses ( ) for the SFC-010 are the values when d1 or d2 is ø8 mm.

* Compatible lengths L range from the minimum L dimension to the maximum L dimension shown in the above table. Specify in 1 mm units.

* When the L dimension is shorter than the standard, the left/right clamping bolt phases will be off by 45°.

* Check "Standard Bore Diameters" for SFC-□DA2 for the standard bore diameters.

For keyway milling applicationsIf you are using a keyed shaft, we can mill a keyway in the clamping hub to your specifications.

SFC-□SA2/DA2

[Dimensions]

| H9 keyway width standards | JS9 keyway width standards | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore dia. | bore dia. d1/d2 [mm] |

Keyway width W1/W2 [mm] |

Keyway height T1/T2 [mm] |

Nominal bore dia. | bore dia. d1/d2 [mm] |

Keyway width W1/W2 [mm] |

Keyway height T1/T2 [mm] |

Nominal bore dia. | bore dia. d1/d2 [mm] |

Keyway width W1/W2 [mm] |

Keyway height T1/T2 [mm] |

Nominal bore dia. | bore dia. d1/d2 [mm] |

Keyway width W1/W2 [mm] |

Keyway height T1/T2 [mm] |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| bore dia. |

Shaft tolerance |

bore dia. |

Shaft tolerance |

bore dia. |

Shaft tolerance |

bore dia. |

Shaft tolerance |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| h7 | j6 | k6 | h7 | j6 | k6 | h7 | j6 | k6 | h7 | j6 | k6 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | BH | - | KH | 8 | 3+0.0250 | 9.4+0.30 | 20 | BH | - | - | 20 | 6+0.0300 | 22.8+0.30 | 8 | BJ | - | KJ | 8 | 3±0.0125 | 9.4+0.30 | 20 | BJ | - | - | 20 | 6±0.0150 | 22.8+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | BH | - | KH | 9 | 3+0.0250 | 10.4+0.30 | 22 | BH | JH | KH | 22 | 6+0.0300 | 24.8+0.30 | 9 | BJ | - | KJ | 9 | 3±0.0125 | 10.4+0.30 | 22 | BJ | JJ | KJ | 22 | 6±0.0150 | 24.8+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | BH | - | - | 10 | 3+0.0250 | 11.4+0.30 | 24 | BH | JH | KH | 24 | 8+0.0360 | 27.3+0.30 | 10 | BJ | - | - | 10 | 3±0.0125 | 11.4+0.30 | 24 | BJ | JJ | KJ | 24 | 8±0.0180 | 27.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 | BH | - | - | 11 | 4+0.0300 | 12.8+0.30 | 25 | BH | - | - | 25 | 8+0.0360 | 28.3+0.30 | 11 | BJ | - | - | 11 | 4±0.0150 | 12.8+0.30 | 25 | BJ | - | - | 25 | 8±0.0180 | 28.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 | BH | - | - | 12 | 4+0.0300 | 13.8+0.30 | 28 | BH | JH | - | 28 | 8+0.0360 | 31.3+0.30 | 12 | BJ | - | - | 12 | 4±0.0150 | 13.8+0.30 | 28 | BJ | JJ | - | 28 | 8±0.0180 | 31.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 | BH | - | - | 13 | 5+0.0300 | 15.3+0.30 | 30 | BH | - | - | 30 | 8+0.0360 | 33.3+0.30 | 13 | BJ | - | - | 13 | 5±0.0150 | 15.3+0.30 | 30 | BJ | - | - | 30 | 8±0.0180 | 33.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 | BH | - | KH | 14 | 5+0.0300 | 16.3+0.30 | 32 | BH | - | KH | 32 | 10+0.0360 | 35.3+0.30 | 14 | BJ | - | KJ | 14 | 5±0.0150 | 16.3+0.30 | 32 | BJ | - | KJ | 32 | 10±0.0180 | 35.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 | BH | - | - | 15 | 5+0.0300 | 17.3+0.30 | 35 | BH | - | - | 35 | 10+0.0360 | 38.3+0.30 | 15 | BJ | - | - | 15 | 5±0.0150 | 17.3+0.30 | 35 | BJ | - | - | 35 | 10±0.0180 | 38.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 | BH | - | KH | 16 | 5+0.0300 | 18.3+0.30 | 38 | BH | - | KH | 38 | 10+0.0360 | 41.3+0.30 | 16 | BJ | - | KJ | 16 | 5±0.0150 | 18.3+0.30 | 38 | BJ | - | KJ | 38 | 10±0.0180 | 41.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | BH | - | - | 17 | 5+0.0300 | 19.3+0.30 | 40 | BH | - | - | 40 | 12+0.4300 | 43.3+0.30 | 17 | BJ | - | - | 17 | 5±0.0150 | 19.3+0.30 | 40 | BJ | - | - | 40 | 12±0.0215 | 43.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 | BH | - | - | 18 | 6+0.0300 | 20.8+0.30 | 42 | BH | - | - | 42 | 12+0.4300 | 45.3+0.30 | 18 | BJ | - | - | 18 | 6±0.0150 | 20.8+0.30 | 42 | BJ | - | - | 42 | 12±0.0215 | 45.3+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 | BH | JH | KH | 19 | 6+0.0300 | 21.8+0.30 | 45 | BH | - | - | 45 | 14+0.4300 | 48.8+0.30 | 19 | BJ | JJ | KJ | 19 | 6±0.0150 | 21.8+0.30 | 45 | BJ | - | - | 45 | 14±0.0215 | 48.8+0.30 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

* Bore diameter of φ35 (nominal diameter B), the shaft tolerance is -0.025 to +0.010 .

* We can also handle standards not listed above. Consult MIKI PULLEY.

[Standard bore diameters]

| Standard (option) bore diameter, d1/d2 [mm] and restricted rated torque [N·m] | ||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal bore dia. | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | |

| Shaft tolerance h7(h6/g6) | B | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Shaft tolerance j6(option) | J | ○ | ○ | ○ | ○ | |||||||||||||||||||||

| Shaft tolerance k6(option) | K | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ○ | ||||||||||||||||

| SFC-025 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| SFC-030 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFC-035 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFC-040 | d1 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| d2 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| SFC-050 | d1 | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||

| d2 | 18 | 20 | 22 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||

| SFC-055 | d1 | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| d2 | 31 | 34 | 36 | 38 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| SFC-060 | d1 | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| d2 | 50 | 51 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-080 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SFC-090 | d1 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||||

| SFC-100 | d1 | 226 | ● | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 226 | ● | ● | ● | ● | ● | ||||||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Shaft tolerances j6/k6: designations J/K are optional, and are only supported for bore diameters marked with ○ .

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

Clean room compatibleIt is a clean room compatible product that has been cleaned, assembled (ISO class 6) and packed in consideration of its use in clean rooms.

SFC-□SA2(CC/CF)

[Specifications]

| Model | shape TYPE | Rated torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg・m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] |

Angular [°] |

Axial [mm] |

||||||||

| SFC-020SA2 | C | 2 | 0.02 | 1 | ±0.15 | 10000 | 3700 | 64 | 2.39×10-6 | 0.025 |

| SFC-025SA2 | C | 4 | 0.02 | 1 | ±0.19 | 10000 | 5600 | 60 | 3.67×10-6 | 0.029 |

| SFC-030SA2 | A | 5 | 0.02 | 1 | ±0.2 | 10000 | 8000 | 64 | 4.09×10-6 | 0.034 |

| B | 6.11×10-6 | 0.040 | ||||||||

| C | 8.23×10-6 | 0.048 | ||||||||

| SFC-035SA2 | C | 10 | 0.02 | 1 | ±0.25 | 10000 | 18000 | 112 | 18.50×10-6 | 0.083 |

| SFC-040SA2 | A | 12 | 0.02 | 1 | ±0.3 | 10000 | 20000 | 80 | 16.71×10-6 | 0.077 |

| B | 22.59×10-6 | 0.085 | ||||||||

| C | 29.28×10-6 | 0.100 | ||||||||

| SFC-050SA2 | A | 25 | 0.02 | 1 | ±0.4 | 10000 | 32000 | 48 | 56.26×10-6 | 0.160 |

| B | 76.71×10-6 | 0.178 | ||||||||

| C | 99.38×10-6 | 0.207 | ||||||||

| SFC-055SA2 | C | 40 | 0.02 | 1 | ±0.42 | 10000 | 50000 | 43 | 188.7×10-6 | 0.315 |

| SFC-060SA2 | A | 60 | 0.02 | 1 | ±0.45 | 10000 | 70000 | 76.4 | 147.0×10-6 | 0.285 |

| B | 206.3×10-6 | 0.328 | ||||||||

| C | 270.0×10-6 | 0.387 | ||||||||

| SFC-080SA2 | C | 100 | 0.02 | 1 | ±0.55 | 10000 | 140000 | 128 | 716.3×10-6 | 0.720 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* Check the Standard Bore Diameter list as rated torque may be restricted by the holding power of the shaft connection component.

* Max. rotation speed does not take into account dynamic balance. * Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | shape TYPE | d1 | d2 | D | N | L | LF | S | A1 | A2 | C | K | M | Tightening torque [N・m] |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | CC Low dust | CF Fluorine | ||||||||||||

| SFC-020SA2 | C | 5 | 10 | 5 | 11 | 26 | - | 23.15 | 10.75 | 1.65 | - | 9.5 | 3.3 | 10.6 | 1-M2.5 | 0.5 | 0.9 |

| SFC-025SA2 | C | 5 | 14 | 5 | 14 | 29 | - | 23.4 | 10.75 | 1.9 | - | 11 | 3.3 | 14.5 | 1-M2.5 | 0.5 | 0.9 |

| SFC-030SA2 | A | 5 | 10 | 5 | 10 | 34 | 21.6 | 27.3 | 12.4 | 2.5 | 8 | - | 3.75 | 14.5 | 1-M3 | 1.5 | 3.2 |

| B | Over 10 | 16 | 12.5 | ||||||||||||||

| C | Over 10 | 14 | - | - | |||||||||||||

| SFC-035SA2 | C | 6 | 16 | 6 | 19 | 39 | - | 34 | 15.5 | 3 | - | 14 | 4.5 | 17 | 1-M4 | 4 | 7.7 |

| SFC-040SA2 | A | 8 | 15 | 8 | 15 | 44 | 29.6 | 34 | 15.5 | 3 | 11 | - | 4.5 | 19.5 | 1-M4 | 4 | 7.7 |

| B | Over 15 | 24 | 17 | ||||||||||||||

| C | Over 15 | 19 | - | - | |||||||||||||

| SFC-050SA2 | A | 8 | 19 | 8 | 19 | 56 | 38 | 43.4 | 20.5 | 2.4 | 14.5 | - | 6 | 26 | 1-M5 | 7 | 12 |

| B | Over 19 | 30 | 22 | ||||||||||||||

| C | Over 19 | 25 | - | - | |||||||||||||

| SFC-055SA2 | C | 10 | 30 | 10 | 30 | 63 | - | 50.6 | 24 | 2.6 | - | 23 | 7.75 | 31 | 1-M6 | 13 | 22.5 |

| SFC-060SA2 | A | 11 | 24 | 11 | 24 | 68 | 46 | 53.6 | 25.2 | 3.2 | 17.5 | - | 7.75 | 31 | 1-M6 | 13 | 22.5 |

| B | Over 24 | 35 | 26.5 | ||||||||||||||

| C | Over 24 | 30 | - | - | |||||||||||||

| SFC-080SA2 | C | 18 | 35 | 18 | 40 | 82 | - | 68 | 30 | 8 | - | 28 | 9 | 38 | 1-M8 | 27 | 45 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* The K dimension is the inner diameter of the element. For d2 dimension exceeding this value, shaft can be inserted only up to LF dimension to the d2 side hub.

* The nominal diameter for the clamping bolt M is equal to the quantity minus the nominal diameter of the screw threads, where the quantity is for a hub on one side.

* You can choose from two types of grease for clamp bolts: low dust generation grease and fluorine grease.

[Standard bore diameters] (Low dust generation grease)

| Model | Standard bore diameter, d1/d2 [mm] and restricted rated torque [N・m] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1/d2 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | |

| SFC-020SA2 | d1 | 0.5 | 0.6 | 0.6 | 0.6 | 1.0 | 1.3 | 1.3 | ● | |||||||||||||||||||

| d2 | 0.5 | 0.6 | 0.6 | 0.6 | 1.0 | 1.3 | 1.3 | ● | ● | |||||||||||||||||||

| SFC-025SA2 | d1 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 0.8 | 1.8 | 1.8 | 2.3 | 2.3 | ● | |||||||||||||||

| d2 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 0.8 | 1.8 | 1.8 | 2.3 | 2.3 | ● | ||||||||||||||||

| SFC-030SA2 | d1 | 0.8 | 1.6 | 2 | 2.6 | 3.4 | 4.4 | 4.9 | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | 0.8 | 1.6 | 2 | 2.6 | 3.4 | 4.4 | 4.9 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SFC-035SA2 | d1 | 3.3 | 3.8 | 4.8 | 6.3 | 7.7 | 8.5 | 9.2 | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 3.3 | 3.8 | 4.8 | 6.3 | 7.7 | 8.5 | 9.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-040SA2 | d1 | 9 | 9 | 9 | 9 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 9 | 9 | 9 | 9 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-050SA2 | d1 | 11 | 16 | 17 | 19 | 19 | 24 | 24 | 24 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| d2 | 11 | 16 | 17 | 19 | 19 | 24 | 24 | 24 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-055SA2 | d1 | 20 | 24 | 29 | 33 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| d2 | 20 | 24 | 29 | 33 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-060SA2 | d1 | 38 | 41 | 44 | 48 | 55 | 55 | 58 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| d2 | 38 | 41 | 44 | 48 | 55 | 55 | 58 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFC-080SA2 | d1 | 54 | 60 | 65 | 75 | 85 | 90 | ● | ● | ● | ● | |||||||||||||||||

| d2 | 54 | 60 | 65 | 75 | 85 | 90 | ● | ● | ● | ● | ● | ● | ||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

[Standard bore diameters] (Fluorine grease)

| Model | Standard bore diameter, d1/d2 [mm] and restricted rated torque [N・m] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1/d2 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | |

| SFC-020SA2 | d1 | 0.7 | 0.7 | 0.7 | 0.8 | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 0.7 | 0.7 | 0.7 | 0.8 | ● | ● | ● | ● | ● | |||||||||||||||||||

| SFC-025SA2 | d1 | 0.5 | 0.5 | 0.5 | 1.1 | 1.6 | 1.6 | 1.6 | 3.2 | 3.2 | ● | ● | ● | |||||||||||||||

| d2 | 0.5 | 0.5 | 0.5 | 1.1 | 1.6 | 1.6 | 1.6 | 3.2 | 3.2 | ● | ● | ● | ||||||||||||||||

| SFC-030SA2 | d1 | 0.8 | 2 | 2.4 | 3.1 | 4.3 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | 0.8 | 2 | 2.4 | 3.1 | 4.3 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SFC-035SA2 | d1 | 3.6 | 5.2 | 6.4 | 8.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 3.6 | 5.2 | 6.4 | 8.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-040SA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-050SA2 | d1 | 11 | 17 | 19 | 20 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| d2 | 11 | 17 | 19 | 20 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-055SA2 | d1 | 28 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| d2 | 28 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-060SA2 | d1 | 40 | 44 | 49 | 53 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| d2 | 40 | 44 | 49 | 53 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFC-080SA2 | d1 | 60 | 66 | 71 | 81 | 90 | 95 | ● | ● | ● | ● | |||||||||||||||||

| d2 | 60 | 66 | 71 | 81 | 90 | 95 | ● | ● | ● | ● | ● | ● | ||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

SFC-□DA2(CC/CF)

[Specifications]

| Model | shape TYPE | Rated torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg・m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] |

Angular [°] |

Axial [mm] |

||||||||

| SFC-020DA2 | C | 2 | 0.15 | 1(On one side) | ±0.33 | 10000 | 1850 | 32 | 3.43×10-6 | 0.035 |

| SFC-025DA2 | C | 4 | 0.16 | 1(On one side) | ±0.38 | 10000 | 2800 | 30 | 5.26×10-6 | 0.040 |

| SFC-030DA2 | A | 5 | 0.18 | 1(On one side) | ±0.4 | 10000 | 4000 | 32 | 7.46×10-6 | 0.054 |

| B | 9.49×10-6 | 0.060 | ||||||||

| C | 11.60×10-6 | 0.069 | ||||||||

| SFC-035DA2 | C | 10 | 0.24 | 1(On one side) | ±0.5 | 10000 | 9000 | 562 | 27.03×10-6 | 0.122 |

| SFC-040DA2 | A | 12 | 0.24 | 1(On one side) | ±0.6 | 10000 | 10000 | 40 | 30.03×10-6 | 0.124 |

| B | 35.81×10-6 | 0.132 | ||||||||

| C | 42.60×10-6 | 0.147 | ||||||||

| SFC-050DA2 | A | 25 | 0.28 | 1(On one side) | ±0.8 | 10000 | 16000 | 24 | 99.32×10-6 | 0.252 |

| B | 119.8×10-6 | 0.270 | ||||||||

| C | 142.4×10-6 | 0.299 | ||||||||

| SFC-055DA2 | C | 40 | 0.31 | 1(On one side) | ±0.84 | 10000 | 25000 | 21.5 | 262.3×10-6 | 0.436 |

| SFC-060DA2 | A | 60 | 0.34 | 1(On one side) | ±0.9 | 10000 | 35000 | 38.2 | 258.6×10-6 | 0.450 |

| B | 317.8×10-6 | 0.493 | ||||||||

| C | 381.6×10-6 | 0.552 | ||||||||

| SFC-080DA2 | C | 100 | 0.52 | 1(On one side) | ±1.10 | 10000 | 70000 | 64 | 1047×10-6 | 1.050 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* Check the Standard Bore Diameter list as rated torque may be restricted by the holding power of the shaft connection component.

* Max. rotation speed does not take into account dynamic balance. * Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | shape TYPE | d1 | d2 | D | N | L | LF | LP | S | A1 | A2 | C | d3 | K | M | Tightening torque [N・m] |

|||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Min. | Max. | Min. | Max. | CC Low dust | CF Fluorine | ||||||||||||||

| SFC-020DA2 | C | 5 | 10 | 5 | 11 | 26 | - | 32.3 | 10.75 | 7.5 | 1.65 | - | 9.5 | 3.3 | 10.6 | 10.6 | 1-M2.5 | 0.5 | 0.9 |

| SFC-025DA2 | C | 5 | 14 | 5 | 14 | 29 | - | 32.8 | 10.75 | 7.5 | 1.9 | - | 11 | 3.3 | 15 | 14.5 | 1-M2.5 | 0.5 | 0.9 |

| SFC-030DA2 | A | 5 | 10 | 5 | 10 | 34 | 21.6 | 37.8 | 12.4 | 8 | 2.5 | 8 | - | 3.75 | 15 | 14.5 | 1-M3 | 1.5 | 3.2 |

| B | Over 10 | 16 | 12.5 | ||||||||||||||||

| C | Over 10 | 14 | - | - | |||||||||||||||

| SFC-035DA2 | C | 6 | 16 | 6 | 19 | 39 | - | 48 | 15.5 | 11 | 3 | - | 14 | 4.5 | 17 | 17 | 1-M4 | 4 | 7.7 |

| SFC-040DA2 | A | 8 | 15 | 8 | 15 | 44 | 29.6 | 48 | 15.5 | 11 | 3 | 11 | - | 4.5 | 20 | 19.5 | 1-M4 | 4 | 7.7 |

| B | Over 15 | 24 | 17 | ||||||||||||||||

| C | Over 15 | 24 | - | - | |||||||||||||||

| SFC-050DA2 | A | 8 | 19 | 8 | 19 | 56 | 38 | 59.8 | 20.5 | 14 | 2.4 | 14.5 | - | 6 | 26 | 26 | 1-M5 | 7 | 12 |

| B | Over 19 | 30 | 22 | ||||||||||||||||

| C | Over 19 | 25 | - | - | |||||||||||||||

| SFC-055DA2 | C | 10 | 30 | 10 | 30 | 63 | - | 68.7 | 24 | 15.5 | 2.6 | - | 23 | 7.75 | 31 | 31 | 1-M6 | 13 | 22.5 |

| SFC-060DA2 | A | 11 | 24 | 11 | 24 | 68 | 46 | 73.3 | 25.2 | 16.5 | 3.2 | 17.5 | - | 7.75 | 31 | 31 | 1-M6 | 13 | 22.5 |

| B | Over 24 | 35 | 26.5 | ||||||||||||||||

| C | Over 24 | 30 | - | - | |||||||||||||||

| SFC-080DA2 | C | 18 | 35 | 18 | 40 | 82 | - | 98 | 30 | 22 | 8 | - | 28 | 9 | 40 | 38 | 1-M8 | 27 | 45 |

* Types A / B / C are automatically specified by Miki Pulley according to the combination of bore diameters you select, and cannot be specified by the customer.

* The K dimension is the inner diameter of the element. For d2 dimension exceeding this value, shaft can be inserted only up to LF dimension to the d2 side hub.

* The nominal diameter for the clamping bolt M is equal to the quantity minus the nominal diameter of the screw threads, where the quantity is for a hub on one side.

* You can choose from two types of grease for clamp bolts: low dust generation grease and fluorine grease.

[Standard bore diameters] (Low dust generation grease)

| Model | Standard bore diameter, d1/d2 [mm] and restricted rated torque [N・m] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1/d2 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | |

| SFC-020DA2 | d1 | 0.5 | 0.6 | 0.6 | 0.6 | 1.0 | 1.3 | 1.3 | ● | |||||||||||||||||||

| d2 | 0.5 | 0.6 | 0.6 | 0.6 | 1.0 | 1.3 | 1.3 | ● | ● | |||||||||||||||||||

| SFC-025DA2 | d1 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 0.8 | 1.8 | 1.8 | 2.3 | 2.3 | ● | |||||||||||||||

| d2 | 0.5 | 0.5 | 0.5 | 0.5 | 0.8 | 0.8 | 0.8 | 1.8 | 1.8 | 2.3 | 2.3 | ● | ||||||||||||||||

| SFC-030DA2 | d1 | 0.8 | 1.6 | 2 | 2.6 | 3.4 | 4.4 | 4.9 | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | 0.8 | 1.6 | 2 | 2.6 | 3.4 | 4.4 | 4.9 | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SFC-035DA2 | d1 | 3.3 | 3.8 | 4.8 | 6.3 | 7.7 | 8.5 | 9.2 | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 3.3 | 3.8 | 4.8 | 6.3 | 7.7 | 8.5 | 9.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-040DA2 | d1 | 9 | 9 | 9 | 9 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 9 | 9 | 9 | 9 | 9 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-050DA2 | d1 | 11 | 16 | 17 | 19 | 19 | 24 | 24 | 24 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| d2 | 11 | 16 | 17 | 19 | 19 | 24 | 24 | 24 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-055DA2 | d1 | 20 | 24 | 29 | 33 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| d2 | 20 | 24 | 29 | 33 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-060DA2 | d1 | 38 | 41 | 44 | 48 | 55 | 55 | 58 | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| d2 | 38 | 41 | 44 | 48 | 55 | 55 | 58 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFC-080DA2 | d1 | 54 | 60 | 65 | 75 | 85 | 90 | ● | ● | ● | ● | |||||||||||||||||

| d2 | 54 | 60 | 65 | 75 | 85 | 90 | ● | ● | ● | ● | ● | ● | ||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

[Standard bore diameters] (Fluorine grease)

| Model | Standard bore diameter, d1/d2 [mm] and restricted rated torque [N・m] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d1/d2 | 5 | 6 | 6.35 | 7 | 8 | 9 | 9.525 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | |

| SFC-020DA2 | d1 | 0.7 | 0.7 | 0.7 | 0.8 | ● | ● | ● | ● | |||||||||||||||||||

| d2 | 0.7 | 0.7 | 0.7 | 0.8 | ● | ● | ● | ● | ● | |||||||||||||||||||

| SFC-025DA2 | d1 | 0.5 | 0.5 | 0.5 | 1.1 | 1.6 | 1.6 | 1.6 | 3.2 | 3.2 | ● | ● | ● | |||||||||||||||

| d2 | 0.5 | 0.5 | 0.5 | 1.1 | 1.6 | 1.6 | 1.6 | 3.2 | 3.2 | ● | ● | ● | ||||||||||||||||

| SFC-030DA2 | d1 | 0.8 | 2 | 2.4 | 3.1 | 4.3 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| d2 | 0.8 | 2 | 2.4 | 3.1 | 4.3 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| SFC-035DA2 | d1 | 3.6 | 5.2 | 6.4 | 8.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | 3.6 | 5.2 | 6.4 | 8.2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-040DA2 | d1 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||

| d2 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-050DA2 | d1 | 11 | 17 | 19 | 20 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| d2 | 11 | 17 | 19 | 20 | 22 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFC-055DA2 | d1 | 28 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| d2 | 28 | 37 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFC-060DA2 | d1 | 40 | 44 | 49 | 53 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| d2 | 40 | 44 | 49 | 53 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFC-080DA2 | d1 | 60 | 66 | 71 | 81 | 90 | 95 | ● | ● | ● | ● | |||||||||||||||||

| d2 | 60 | 66 | 71 | 81 | 90 | 95 | ● | ● | ● | ● | ● | ● | ||||||||||||||||

* The shaft tolerance for standard bore diameter is h7 (h6 or g6): designation B. However, for a bore diameter of ø35, the shaft tolerance is -0.025 to +0.010.

* Bore diameters marked with ● or numbers are supported as the standard bore diameters. Consult Miki Pulley regarding special arrangements which may be possible for other bore diameters.

* Bore diameters whose fields contain numbers are restricted in their rated torque by the holding power of the shaft connection component because the bore diameter is small. The numbers indicate the rated torque [N・m].

Related Product

- Max. rated torque 8000 N・m

- Standard bore-drilling range 22 mm to 115 mm

- Backlash Zero

- Max. rated torque 220 N・m

- Bore ranges 3 mm to 35 mm

- Operating temperature -30℃ to 100℃

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어