![]()

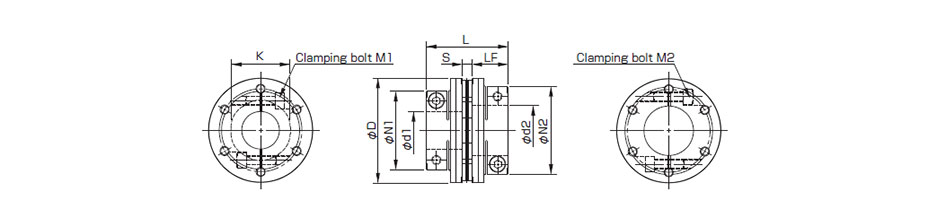

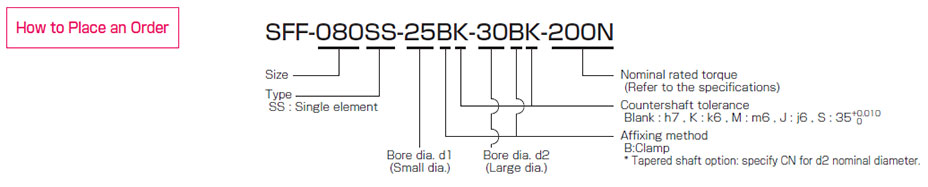

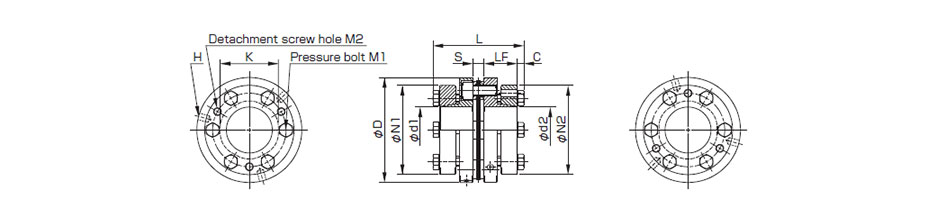

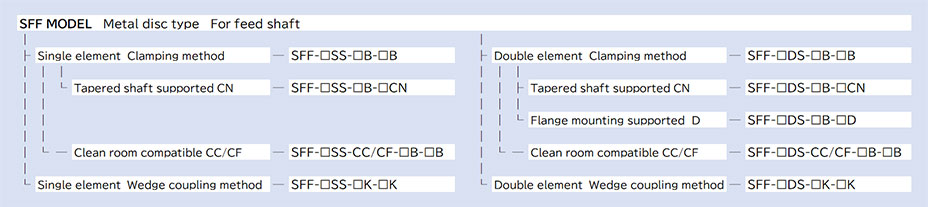

Options of SFF Models

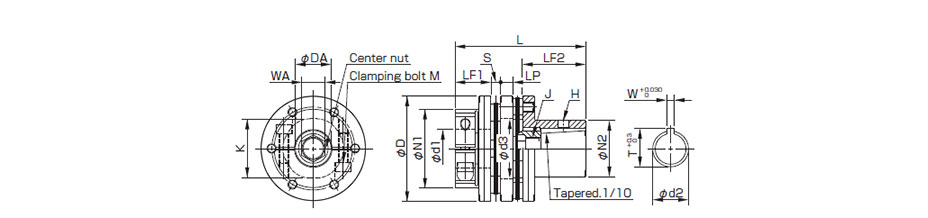

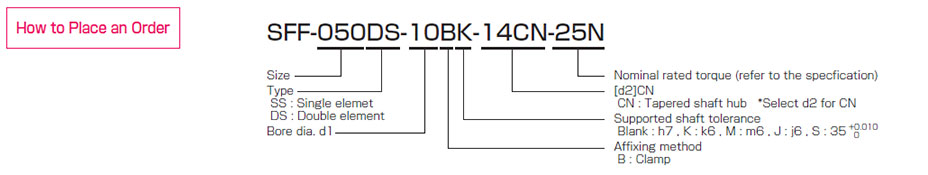

Tapered shaft supported Single elementSupports servo motor tapered shafts.

[Specifications]

| Model | Rated Torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg/m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] | Angular [°] | Axial [mm] | |||||||

| SFF-040SS-□B-11CN-8N | 8 | 0.02 | 1 | ±0.2 | 18000 | 15000 | 174 | 0.03×10-3 | 0.2 |

| SFF-040SS-□B-11CN-12N | 12 | 0.02 | 1 | ±0.2 | 18000 | 15000 | 174 | 0.03×10-3 | 0.18 |

| SFF-050SS-□B-14CN-25N | 25 | 0.02 | 1 | ±0.3 | 18000 | 32000 | 145 | 0.09×10-3 | 0.36 |

| SFF-050SS-□B-16CN-25N | 25 | 0.02 | 1 | ±0.3 | 18000 | 32000 | 145 | 0.10×10-3 | 0.41 |

| SFF-060SS-□B-16CN-60N | 60 | 0.02 | 1 | ±0.3 | 18000 | 104000 | 399 | 0.18×10-3 | 0.54 |

| SFF-060SS-□B-16CN-80N | 80 | 0.02 | 1 | ±0.3 | 18000 | 104000 | 399 | 0.19×10-3 | 0.52 |

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

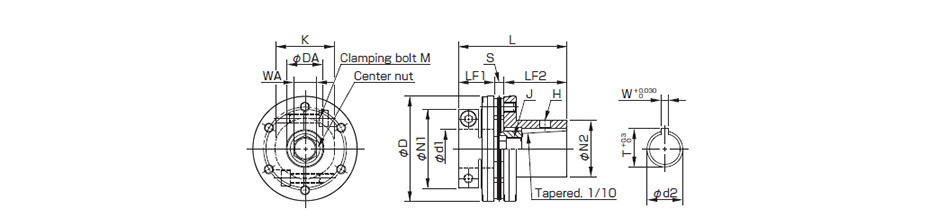

[Dimensions]

| Model | d1 [mm] |

d2 [mm] |

W [mm] |

T [mm] |

D [mm] |

L [mm] |

N1 [mm] |

N2 [mm] |

LF1 [mm] |

LF2 [mm] |

S [mm] |

K [mm] |

H [mm] |

M Qty - nominal dia | M Tightening torque [N・m] | DA [mm] |

WA [mm] |

J Nominal x pitch | J Tightening torque [N・m] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFF-040SS-□B-11CN-8N | 8~9.525 | 11 | 4 | 12.2 | 38 | 46.4 | 33 | 22 | 17.5 | 25 | 3.9 | 17 | 5.1 | 2-M4 | 3.4 | 12 | 6 | M6×1.0 | 10 |

| SFF-040SS-□B-11CN-12N | 10~16 | 11 | 4 | 12.2 | 38 | 46.4 | 33 | 22 | 17.5 | 25 | 3.9 | 17 | 5.1 | 2-M4 | 3.4 | 12 | 6 | M6×1.0 | 10 |

| SFF-050SS-□B-14CN-25N | 10~19 | 14 | 4 | 15.1 | 48 | 56.9 | 42 | 27.5 | 21.5 | 30 | 5.4 | 20 | 5.1 | 2-M5 | 7 | 15 | 8 | M8×1.0 | 20 |

| SFF-050SS-□B-16CN-25N | 10~19 | 16 | 5 | 17.3 | 48 | 67.9 | 42 | 29.5 | 21.5 | 41 | 5.4 | 20 | 6.8 | 2-M5 | 7 | 16 | 10 | M10×1.25 | 30 |

| SFF-060SS-□B-16CN-60N | 12~19 | 16 | 5 | 17.3 | 58 | 70.4 | 44 | 29.5 | 24 | 41 | 5.4 | 32 | 6.8 | 2-M6 | 14 | 16 | 10 | M10×1.25 | 30 |

| SFF-060SS-□B-16CN-80N | 20~22 | 16 | 5 | 17.3 | 58 | 70.4 | 44 | 29.5 | 24 | 41 | 5.4 | 32 | 6.8 | 2-M6 | 14 | 16 | 10 | M10×1.25 | 30 |

| 24~28 | 48 | 2-M5 | 7 | ||||||||||||||||

| 30 | 52 |

[Standard bore diameter]

| Model | Standard bore diameter d1[mm] | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | |

| SFF-040SS-□B-11CN-8N | ● | ● | ● | |||||||||||||||

| SFF-040SS-□B-11CN-12N | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFF-050SS-□B-14CN-25N | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFF-050SS-□B-16CN-25N | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFF-060SS-□B-16CN-60N | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFF-060SS-□B-16CN-80N | ● | ● | ● | ● | ● | ● | ||||||||||||

* The bore diameters marked with ● are supported as standard bore diameter.

Tapered shaft supported Double elementSupports servo motor tapered shafts.

[Specifications]

| Model | Rated Torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg/m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] | Angular [°] | Axial [mm] | |||||||

| SFF-040DS-□B-11CN-8N | 8 | 0.10 | 1(On one side) | ±0.4 | 14000 | 7500 | 87 | 0.04×10-3 | 0.25 |

| SFF-040DS-□B-11CN-12N | 12 | 0.10 | (On one side) | ±0.4 | 14000 | 7500 | 87 | 0.04×10-3 | 0.23 |

| SFF-050DS-□B-14CN-25N | 25 | 0.20 | 1(On one side) | ±0.6 | 14000 | 16000 | 72.5 | 0.12×10-3 | 0.45 |

| SFF-050DS-□B-16CN-25N | 25 | 0.20 | 1(On one side) | ±0.6 | 14000 | 16000 | 72.5 | 0.13×10-3 | 0.49 |

| SFF-060DS-□B-16CN-60N | 60 | 0.20 | 1(On one side) | ±0.6 | 14000 | 52000 | 199.5 | 0.24×10-3 | 0.67 |

| SFF-060DS-□B-16CN-80N | 80 | 0.20 | 1(On one side) | ±0.6 | 14000 | 52000 | 199.5 | 0.26×10-3 | 0.64 |

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | d1 [mm] |

d2 [mm] |

W [mm] |

T [mm] |

D [mm] |

L [mm] |

N1 [mm] |

N2 [mm] |

LF1 [mm] |

LF2 [mm] |

LP [mm] |

S [mm] |

d3 [mm] |

K [mm] |

H [mm] |

M Qty - nominal dia | M Tightening torque [N・m] | DA [mm] |

WA [mm] |

J Nominal x pitch | J Tightening torque[N・m] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFF-040DS-□B-11CN-8N | 8~9.525 | 11 | 4 | 12.2 | 38 | 56.3 | 33 | 22 | 17.5 | 25 | 6 | 3.9 | 17 | 17 | 5.1 | 2-M4 | 3.4 | 12 | 6 | M6×1.0 | 10 |

| SFF-040DS-□B-11CN-12N | 10~16 | 11 | 4 | 12.2 | 38 | 56.3 | 33 | 22 | 17.5 | 25 | 6 | 3.9 | 17 | 17 | 5.1 | 2-M4 | 3.4 | 12 | 6 | M6×1.0 | 10 |

| SFF-050DS-□B-14CN-25N | 10~19 | 14 | 4 | 15.1 | 48 | 69.3 | 42 | 27.5 | 21.5 | 30 | 7 | 5.4 | 20 | 20 | 5.1 | 2-M5 | 7 | 15 | 8 | M8×1.0 | 20 |

| SFF-050DS-□B-16CN-25N | 10~19 | 15 | 5 | 17.3 | 48 | 80.3 | 42 | 29.5 | 21.5 | 41 | 7 | 5.4 | 20 | 20 | 6.8 | 2-M5 | 7 | 16 | 10 | M10×1.25 | 30 |

| SFF-060DS-□B-16CN-60N | 12~19 | 16 | 5 | 17.3 | 58 | 82.8 | 44 | 29.5 | 24 | 41 | 7 | 5.4 | 31 | 32 | 6.8 | 2-M6 | 14 | 16 | 10 | M10×1.25 | 30 |

| SFF-060DS-□B-16CN-80N | 20~22 | 16 | 5 | 17.3 | 58 | 82.8 | 44 | 29.5 | 24 | 41 | 7 | 5.4 | 31 | 32 | 6.8 | 2-M6 | 14 | 16 | 10 | M10×1.25 | 30 |

| 24~28 | 48 | 2-M5 | 7 | ||||||||||||||||||

| 30 | 52 |

[Standard bore diameter]

| Model | Standard bore diameter d1[mm] | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | |

| SFF-040DS-□B-11CN-8N | ● | ● | ● | |||||||||||||||

| SFF-040DS-□B-11CN-12N | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFF-050DS-□B-14CN-25N | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFF-050DS-□B-16CN-25N | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||

| SFF-060DS-□B-16CN-60N | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFF-060DS-□B-16CN-80N | ● | ● | ● | ● | ● | ● | ||||||||||||

* The bore diameters marked with ● are supported as standard bore diameter.

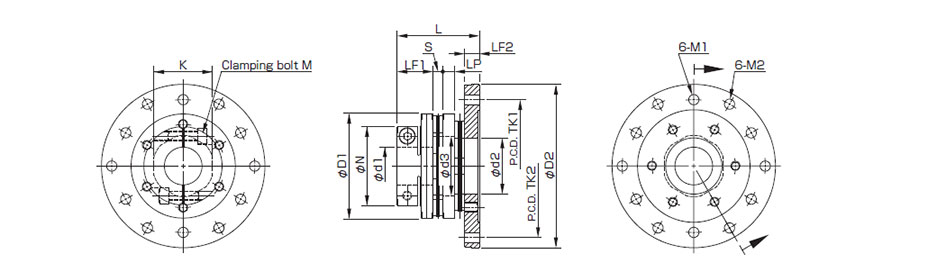

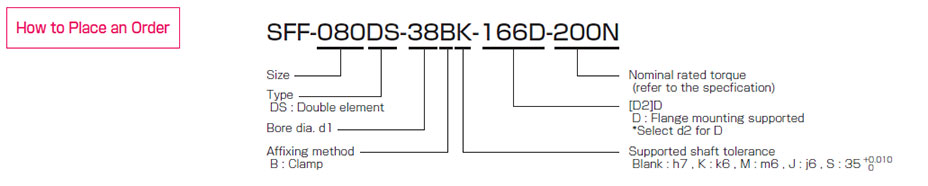

Flange mounting supportedSupports direct drive motor and speed reducer.

[Specifications]

| Model | Rated Torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg/m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] | Angular [°] | Axial [mm] | |||||||

| SFF-070DS-□B-105D-100N | 100 | 0.25 | 1(On one side) | ±1.0 | 1000 | 120000 | 242 | 1.20×10-3 | 1.08 |

| SFF-080DS-□B-166D-200N | 200 | 0.31 | 1(On one side) | ±1.0 | 1000 | 155000 | 273 | 8.35×10-3 | 3.11 |

| SFF-090DS-□B-166D-300N | 300 | 0.32 | 1(On one side) | ±1.2 | 1000 | 260000 | 160.5 | 8.69×10-3 | 3.18 |

| SFF-100DS-□B-166D-450N | 450 | 0.38 | 1(On one side) | ±1.3 | 1000 | 370000 | 270 | 10.01×10-3 | 3.91 |

| SFF-120DS-□B-166D-600N | 600 | 0.38 | 1(On one side) | ±1.6 | 1000 | 485000 | 180 | 12.66×10-3 | 4.57 |

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | d1 [mm] |

d2 [mm] |

D1 [mm] |

D2 [mm] |

L [mm] |

N [mm] |

LF1 [mm] |

LF2 [mm] |

LP [mm] |

S [mm] |

d3 [mm] |

K [mm] |

M1 [mm] |

TK1 [mm] |

M2 [mm] |

TK2 [mm] |

M Qty - nominal dia |

M Tightening torque [N・m] |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SFF-070DS-□B-105D-100N | 28~35 | 36 | 68 | 105 | 54.8 | 56 | 25 | 10 | 8 | 5.9 | 37 | 38 | 6.4 | 86 | 6.4 | 92 | 2-M6 | 14 |

| SFF-080DS-□B-166D-200N | 28~38 | 39 | 78 | 166 | 68.9 | 70(74) | 30 | 13.5 | 10 | 7.7 | 40 | 42 | 6.4 | 150 | 8.6 | 150 | 2-M8 | 34 |

| SFF-090DS-□B-166D-300N | 35~42 | 49 | 88 | 166 | 70.1 | 74 | 30 | 13.5 | 10 | 8.3 | 50 | 50 | 6.4 | 150 | 8.6 | 150 | 2-M8 | 34 |

| SFF-100DS-□B-166D-450N | 32~48 | 51 | 98 | 166 | 85.9 | 84 | 40 | 13.5 | 12 | 10.2 | 52 | 56 | 6.4 | 150 | 8.6 | 150 | 2-M10 | 68 |

| SFF-120DS-□B-166D-600N | 48~55 | 67 | 118 | 166 | 85.9 | 100 | 40 | 13.5 | 12 | 10.2 | 72 | 68 | 6.4 | 150 | 8.6 | 150 | 2-M10 | 68 |

* The figures in parentheses ( ) for the SFF-080 are the values when d1 is φ38 mm.

* Special arrangements may be possible for mounting holes at the flange end regarding bore diameter, number, and pitch. Check if arrangements are possible.

[Standard bore diameter]

| Model | Standard bore diameter d1 [mm] | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | |

| SFF-070DS-□B-105D-100N | ● | ● | ● | ● | |||||||

| SFF-080DS-□B-166D-200N | ● | ● | ● | ● | ● | ||||||

| SFF-090DS-□B-166D-300N | ● | ● | ● | ● | |||||||

| SFF-100DS-□B-166D-450N | ● | ● | ● | ● | ● | ● | ● | ||||

| SFF-120DS-□B-166D-600N | ● | ● | ● | ||||||||

* The bore diameters marked with ● are supported as standard bore diameter.

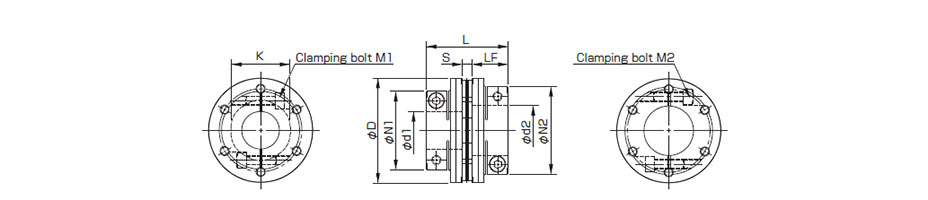

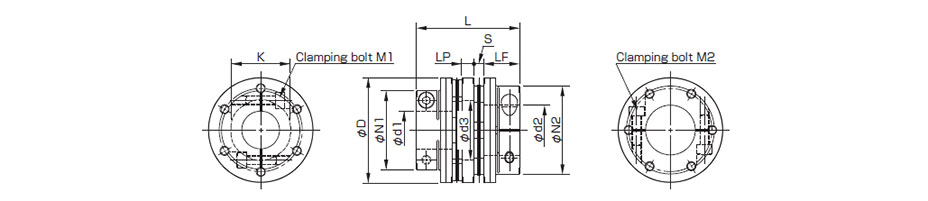

Clean room compatible Single elementIt is a clean room compatible product that has been cleaned, assembled (ISO class 6) and packed in consideration of its use in clean rooms.

[Specifications]

| Model | Rated Torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg/m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] | Angular [°] | Axial [mm] | |||||||

| SFF-040SS-□-□B-□B-8N | 8 | 0.02 | 1 | ±0.2 | 18000 | 15000 | 174 | 0.03×10 -3 | 0.17 |

| SFF-050SS-□-□B-□B-16N | 16 | 0.02 | 1 | ±0.3 | 18000 | 32000 | 145 | 0.10×10 -3 | 0.36 |

| SFF-060SS-□-□B-□B-40N | 40 | 0.02 | 1 | ±0.3 | 18000 | 104000 | 399 | 0.22×10 -3 | 0.52 |

| SFF-060SS-□-□B-□B-50N | 50 | 0.02 | 1 | ±0.3 | 18000 | 104000 | 399 | 0.23×10 -3 | 0.49 |

| SFF-070SS-□-□B-□B-65N | 65 | 0.02 | 1 | ±0.5 | 18000 | 240000 | 484 | 0.40×10 -3 | 0.72 |

| SFF-080SS-□-□B-□B-120N | 120 | 0.02 | 1 | ±0.5 | 17000 | 310000 | 546 | 1.25×10 -3 | 1.40 |

| SFF-090SS-□-□B-□B-150N | 150 | 0.02 | 1 | ±0.6 | 15000 | 520000 | 321 | 1.58×10-3 | 1.53 |

| SFF-100SS-□-□B-□B-250N | 250 | 0.02 | 1 | ±0.65 | 13000 | 740000 | 540 | 3.27×10-3 | 2.53 |

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | d1 [mm] |

d2 [mm] |

D [mm] |

L [mm] |

N1・N2 [mm] |

LF [mm] |

S [mm] |

K [mm] |

M1・M2 Qty - nominal dia |

Tightening torque [N・m] | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| CC Low dust | CF Fluorine | ||||||||||

| SFF-040SS-□-□B-□B-8N | 8~16 | 8~16 | 38 | 38.9 | 33 | 17.5 | 3.9 | 17 | 2-M4 | 4.5 | 4.5 |

| SFF-050SS-□-□B-□B-16N | 10~19 | 10~19 | 48 | 48.4 | 42 | 21.5 | 5.4 | 20 | 2-M5 | 9 | 8.5 |

| SFF-060SS-□-□B-□B-40N | 12~22 | 12~22 | 58 | 53.4 | 44 | 24 | 5.4 | 32 | 2-M6 | 16 | 16 |

| - | 24~28 | 58 | 53.4 | 48 | 24 | 5.4 | 32 | 2-M5 | 9 | 8.5 | |

| - | 30 | 58 | 53.4 | 52 | 24 | 5.4 | 32 | 2-M5 | 9 | 8.5 | |

| SFF-060SS-□-□B-□B-50N | 24~28 | 24~28 | 58 | 53.4 | 48 | 24 | 5.4 | 32 | 2-M5 | 9 | 8.5 |

| 30 | 30 | 58 | 53.4 | 52 | 24 | 5.4 | 32 | 2-M5 | 9 | 8.5 | |

| SFF-070SS-□-□B-□B-65N | 18~19 | 18~25 | 68 | 55.9 | 47 | 25 | 5.9 | 38 | 2-M6 | 16 | 16 |

| - | 28~35 | 68 | 55.9 | 56 | 25 | 5.9 | 38 | 2-M6 | 16 | 16 | |

| SFF-080SS-□-□B-□B-120N | 28~35 | 28~35 | 78 | 67.7 | 70 | 30 | 7.7 | 42 | 2-M8 | 37 | 45 |

| 38 | 38 | 78 | 67.7 | 74 | 30 | 7.7 | 42 | 2-M8 | 37 | 45 | |

| SFF-090SS-□-□B-□B-150N | 35~42 | 35~42 | 88 | 68.3 | 74 | 30 | 8.3 | 50 | 2-M8 | 37 | 45 |

| SFF-100SS-□-□B-□B-250N | 38~48 | 38~48 | 98 | 90.2 | 84 | 40 | 10.2 | 56 | 2-M10 | 68 | 65 |

* Nominal diameter of clamping bolt M1/M2 is given as number of bolts - nominal diameter, and the number is the number for one hub.

* You can choose from two types of grease for clamp bolts : low dust generation grease and fluorine grease.

[Standard bore diameter]

| Model | Standard bore diameter d1・d2 [mm] | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | |

| SFF-040SS-□-□B-□B-8N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFF-050SS-□-□B-□B-16N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFF-060SS-□-□B-□B-40N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFF-060SS-□-□B-□B-50N | ● | ● | ● | ● | |||||||||||||||||||||

| SFF-070SS-□-□B-□B-65N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| SFF-080SS-□-□B-□B-120N | ● | ● | ● | ● | ● | ||||||||||||||||||||

| SFF-090SS-□-□B-□B-150N | ● | ● | ● | ● | |||||||||||||||||||||

| SFF-100SS-□-□B-□B-250N | ● | ● | ● | ● | ● | ||||||||||||||||||||

* The bore diameters marked with ● are supported as standard bore diameter.

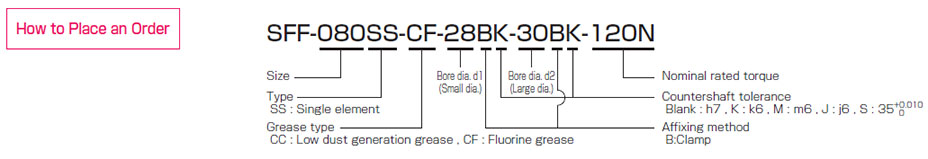

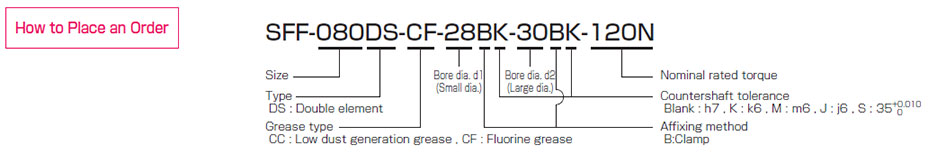

Clean room compatible Double elementIt is a clean room compatible product that has been cleaned, assembled (ISO class 6) and packed in consideration of its use in clean rooms.

[Specifications]

| Model | Rated Torque [N・m] |

Misalignment | Max. rotation speed [min-1] |

Torsional stiffness [N・m/rad] |

Axial stiffness [N/mm] |

Moment of inertia [kg/m2] |

Mass [kg] |

||

|---|---|---|---|---|---|---|---|---|---|

| Parallel [mm] | Angular [°] | Axial [mm] | |||||||

| SFF-040DS-□-□B-□B-8N | 8 | 0.1 | 1(On one side) | ±0.4 | 14000 | 7500 | 87 | 0.04×10 -3 | 0.22 |

| SFF-050DS-□-□B-□B-16N | 16 | 0.2 | 1(On one side) | ±0.6 | 14000 | 16000 | 72.5 | 0.13×10 -3 | 0.46 |

| SFF-060DS-□-□B-□B-40N | 40 | 0.2 | 1(On one side) | ±0.6 | 14000 | 52000 | 199.5 | 0.28×10 -3 | 0.64 |

| SFF-060DS-□-□B-□B-50N | 50 | 0.2 | 1(On one side) | ±0.6 | 14000 | 52000 | 199.5 | 0.29×10 -3 | 0.61 |

| SFF-070DS-□-□B-□B-65N | 65 | 0.25 | 1(On one side) | ±1.0 | 14000 | 120000 | 242 | 0.53×10 -3 | 0.90 |

| SFF-080DS-□-□B-□B-120N | 120 | 0.31 | 1(On one side) | ±1.0 | 13000 | 155000 | 273 | 1.50×10-3 | 1.72 |

| SFF-090DS-□-□B-□B-150N | 150 | 0.32 | 1(On one side) | ±1.2 | 12000 | 260000 | 160.5 | 2.03×10-3 | 2.02 |

| SFF-100DS-□-□B-□B-250N | 250 | 0.38 | 1(On one side) | ±1.3 | 10000 | 370000 | 270 | 4.18×10-3 | 3.12 |

* Max. rotation speed does not take into account dynamic balance.

* Torsional stiffness values given are measured values for the element alone.

* The moment of inertia and mass are measured for the maximum bore diameter.

[Dimensions]

| Model | d1 [mm] |

d2 [mm] |

D [mm] |

L [mm] |

N1・N2 [mm] |

LF [mm] |

LP [mm] |

S [mm] |

d3 [mm] |

K [mm] |

M1・M2 Qty - nominal dia |

Tightening torque [N・m] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CC Low dust | CF Fluorine | ||||||||||||

| SFF-040DS-□-□B-□B-8N | 8~16 | 8~16 | 38 | 48.8 | 33 | 17.5 | 6 | 3.9 | 17 | 17 | 2-M4 | 4.5 | 4.5 |

| SFF-050DS-□-□B-□B-16N | 10~19 | 10~19 | 48 | 60.8 | 42 | 21.5 | 7 | 5.4 | 20 | 20 | 2-M5 | 9 | 8.5 |

| SFF-060DS-□-□B-□B-40N | 12~22 | 12~22 | 58 | 65.8 | 44 | 24 | 7 | 5.4 | 31 | 32 | 2-M6 | 16 | 16 |

| - | 24~28 | 58 | 65.8 | 48 | 24 | 7 | 5.4 | 31 | 32 | 2-M5 | 9 | 8.5 | |

| - | 30 | 58 | 65.8 | 52 | 24 | 7 | 5.4 | 31 | 32 | 2-M5 | 9 | 8.5 | |

| SFF-060DS-□-□B-□B-50N | 24~28 | 24~28 | 58 | 65.8 | 48 | 24 | 7 | 5.4 | 31 | 32 | 2-M5 | 9 | 8.5 |

| 30 | 30 | 58 | 68.5 | 52 | 24 | 7 | 5.4 | 31 | 32 | 2-M5 | 9 | 8.5 | |

| SFF-070DS-□-□B-□B-65N | 18~19 | 18~25 | 68 | 69.8 | 47 | 25 | 8 | 5.9 | 37 | 38 | 2-M6 | 16 | 16 |

| - | 28~35 | 68 | 69.8 | 56 | 25 | 8 | 5.9 | 37 | 38 | 2-M6 | 16 | 16 | |

| SFF-080DS-□-□B-□B-120N | 28~35 | 28~35 | 78 | 85.4 | 70 | 30 | 10 | 7.7 | 40 | 42 | 2-M8 | 37 | 45 |

| 38 | 38 | 78 | 85.4 | 74 | 30 | 10 | 7.7 | 40 | 42 | 2-M8 | 37 | 45 | |

| SFF-090DS-□-□B-□B-150N | 35~42 | 35~42 | 88 | 86.6 | 74 | 30 | 10 | 8.3 | 50 | 50 | 2-M8 | 37 | 45 |

| SFF-100DS-□-□B-□B-250N | 38~48 | 38~48 | 98 | 112.4 | 84 | 40 | 12 | 10.2 | 52 | 56 | 2-M10 | 68 | 65 |

* Nominal diameter of clamping bolt M1/M2 is given as number of bolts - nominal diameter, and the number is the number for one hub.

* You can choose from two types of grease for clamp bolts : low dust generation grease and fluorine grease.

[Standard bore diameter]

| Model | Standard bore diameter d1・d2 [mm] | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 9.525 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | |

| SFF-040DS-□-□B-□B-8N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFF-050DS-□-□B-□B-16N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFF-060DS-□-□B-□B-40N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFF-060DS-□-□B-□B-50N | ● | ● | ● | ● | |||||||||||||||||||||

| SFF-070DS-□-□B-□B-65N | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| SFF-080DS-□-□B-□B-120N | ● | ● | ● | ● | ● | ||||||||||||||||||||

| SFF-090DS-□-□B-□B-150N | ● | ● | ● | ● | |||||||||||||||||||||

| SFF-100DS-□-□B-□B-250N | ● | ● | ● | ● | ● | ||||||||||||||||||||

* The bore diameters marked with ● are supported as standard bore diameter.

Related Product

- Max. nominal torque 5000 N・m

- Pilot-bore additional processing range 9 mm to 130 mm

- Operating temperature -30℃ to 95℃

- Max. nominal torque 7850 N・m

- Max. speed 3000 min-1

- Operating temperature -10℃ to 60℃

- Max. nominal torque 2500 N・m

- Pilot-bore additional processing range 13 mm to 120 mm

- Operating temperature -40℃ to 120℃

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어