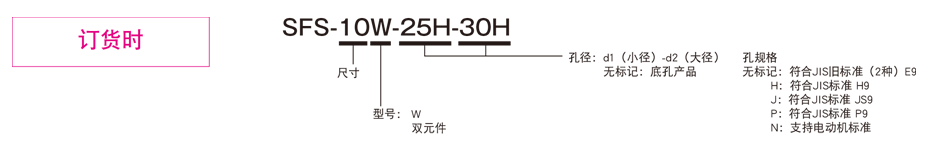

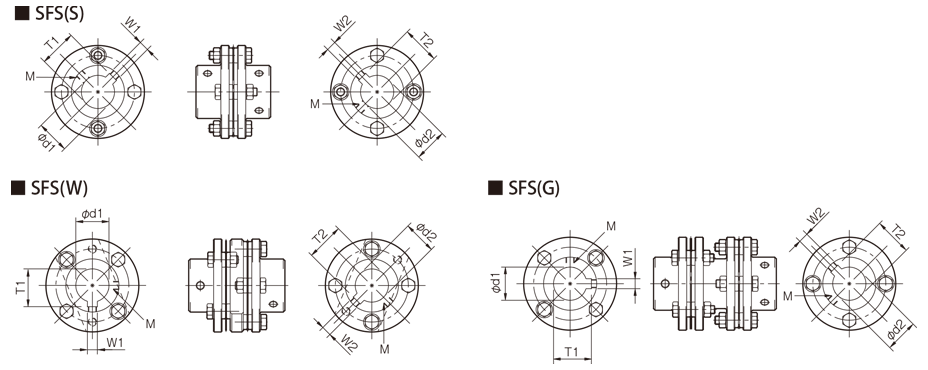

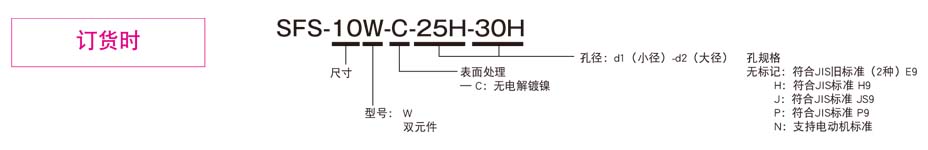

SFS型

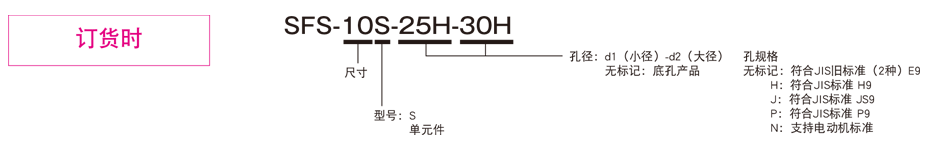

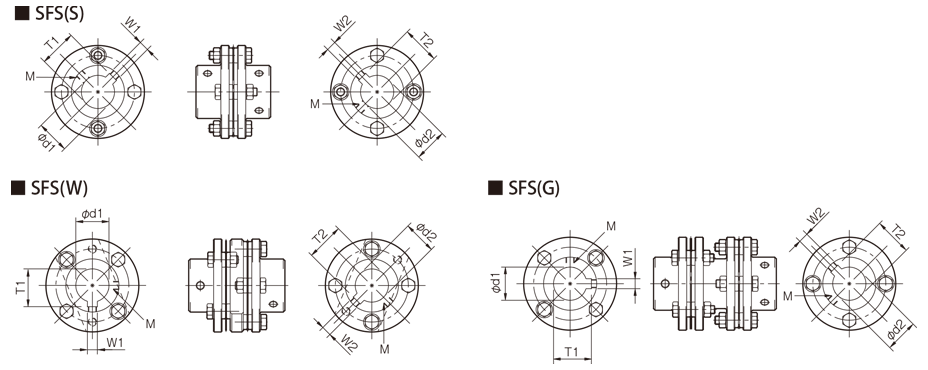

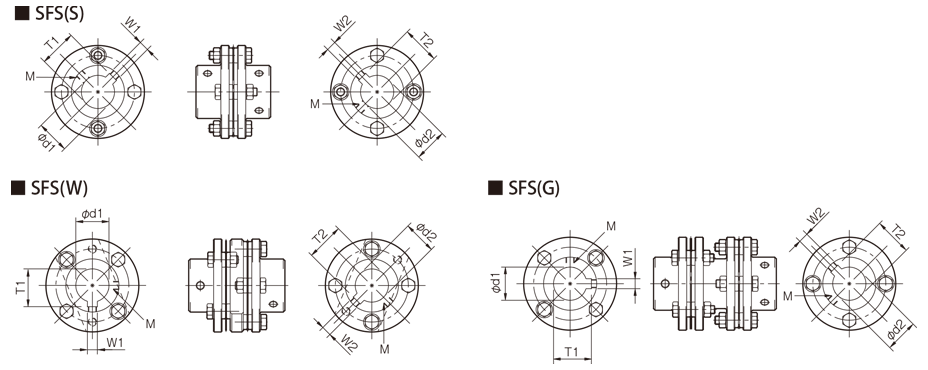

是采用钢材质主体的板簧型联轴器,是伺服挠性联轴器的基本型号。备有高刚性的单元件型和通过隔板配置两个元件、具有灵活性的双元件型,和将双元件与中间法兰组合而成的浮动轴型。

是采用钢材质主体的板簧型联轴器,是伺服挠性联轴器的基本型号。备有高刚性的单元件型和通过隔板配置两个元件、具有灵活性的双元件型,和将双元件与中间法兰组合而成的浮动轴型。

丰富的产品线

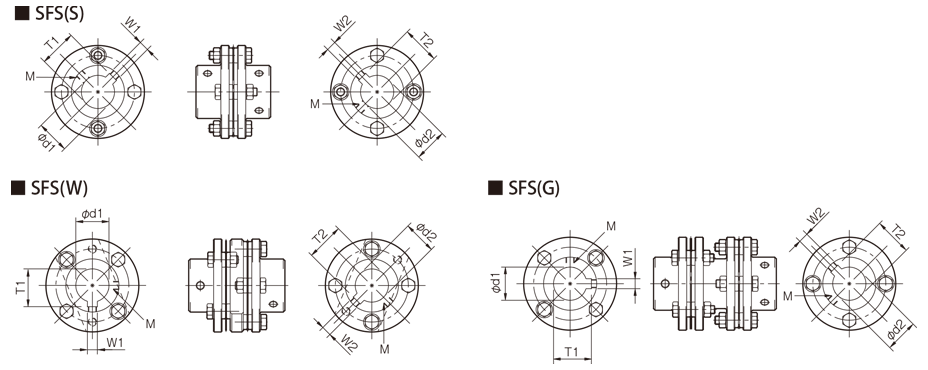

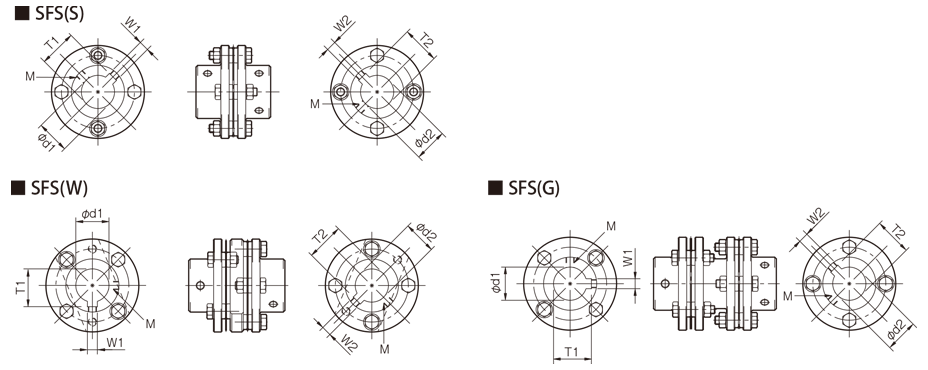

备有高刚性的单元件型SFS S 和通过隔板配置两个元件、具有灵活性的双元件型SFS W,以及将双元件与中间法兰组合而成的浮动轴型SFS G。

还有无电解镀镍型号

底孔产品和键、定位螺钉产品可以选择无电解镀镍的表面处理。

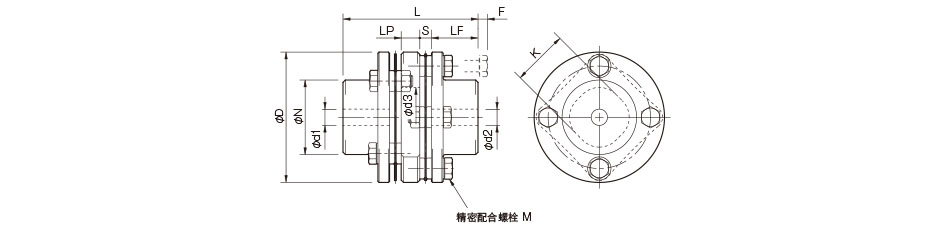

高精度的安装

采用摩擦连接的SFS S/W/G- □ M- □ M型因为是将套筒插入到法兰部内侧的设计,以套筒的外径为导套,能够实现高精度的安装。

能够以部件为单位进行装配

因为是以部件单位交付,即便是在总装状态下无法安装的设计也可以毫无问题地使用。此外,还可根据需要装配好后发货。另外,各法兰在安装尺寸上有兼容性,因此可以实现一侧法兰为底孔产品、与键·定位螺钉型法兰和高精度摩擦连接的法兰相组合的订购方式。

SFS-□S 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 轴向弹性常数[N/mm] | 转动惯量[kg・m2] | 质量[kg] | |

|---|---|---|---|---|---|---|---|---|

| 偏角[°] | 轴向[mm] | |||||||

| SFS-05S | 20 | 1 | ±0.6 | 25000 | 16000 | 43 | 0.11×10-3 | 0.30 |

| SFS-06S | 40 | 1 | ±0.8 | 20000 | 29000 | 45 | 0.30×10-3 | 0.50 |

| SFS-08S | 80 | 1 | ±1.0 | 17000 | 83000 | 60 | 0.87×10-3 | 1.00 |

| SFS-09S | 180 | 1 | ±1.2 | 15000 | 170000 | 122 | 1.60×10-3 | 1.40 |

| SFS-10S | 250 | 1 | ±1.4 | 13000 | 250000 | 160 | 2.60×10-3 | 2.10 |

| SFS-12S | 450 | 1 | ±1.6 | 11000 | 430000 | 197 | 6.50×10-3 | 3.40 |

| SFS-14S | 800 | 1 | ±1.8 | 9500 | 780000 | 313 | 9.90×10-3 | 4.90 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

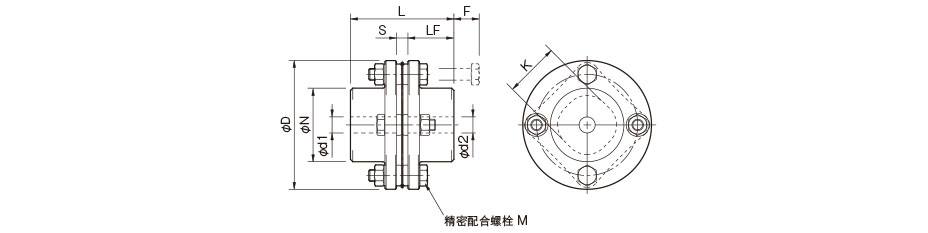

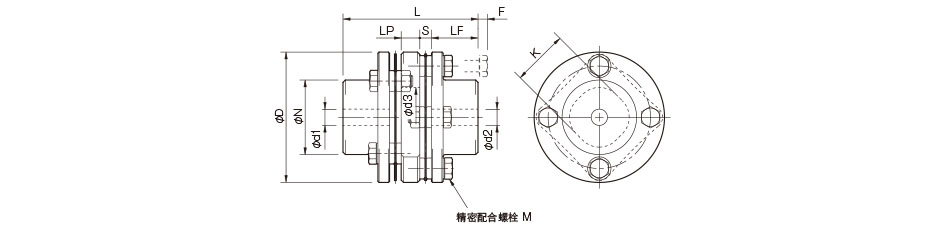

【尺寸】

| 型号 | d1, d2 | D | N | L | LF | S | F | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 底孔 | 最小 | 最大 | |||||||||

| SFS-05S | 7 | 8 | 20 | 56 | 32 | 45 | 20 | 5 | 11 | 24 | 4-M5×22 |

| SFS-06S | 7 | 8 | 25 | 68 | 40 | 56 | 25 | 6 | 10 | 30 | 4-M6×25 |

| SFS-08S | 10 | 11 | 35 | 82 | 54 | 66 | 30 | 6 | 11 | 38 | 4-M6×29 |

| SFS-09S | 10 | 11 | 38 | 94 | 58 | 68 | 30 | 8 | 21 | 42 | 4-M8×36 |

| SFS-10S | 15 | 16 | 42 | 104 | 68 | 80 | 35 | 10 | 16 | 48 | 4-M8×36 |

| SFS-12S | 18 | 19 | 50 | 126 | 78 | 91 | 40 | 11 | 23 | 54 | 4-M10×45 |

| SFS-14S | 20 | 22 | 60 | 144 | 88 | 102 | 45 | 12 | 31 | 61 | 4-M12×54 |

※底孔为钻孔。关于加工,请参阅标准孔加工规格。

※精密配合螺栓M公称为数量-螺钉公称×公称长度。

【标准孔径】

| 型号 | 标准孔径 d1・d2 [mm] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | |

| SFS-05S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFS-06S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-08S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFS-09S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFS-10S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-12S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-14S | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

※ 已有●号的栏其孔径为标准孔径。详情请参考标准孔加工规格。

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | |||||

| 公差H7,H8 | 公差E9 | - | - | 公差H7,H8 | 公差H9 | - | - | 公差H7,H8 | 公差JS9 | - | - | ||||||||

| 8 | 8+0.0220 | - | - | 2-M4 | 8H | 8+0.0220 | 3+0.0250 | 9.4+0.30 | 2-M4 | 8J | 8+0.0220 | 3±0.0125 | 9.4+0.30 | 2-M4 | |||||

| 9 | 9+0.0220 | - | - | 2-M4 | 9H | 9+0.0220 | 3+0.0250 | 10.4+0.30 | 2-M4 | 9J | 9+0.0220 | 3±0.0125 | 10.4+0.30 | 2-M4 | |||||

| 10 | 10+0.0220 | - | - | 2-M4 | 10H | 10+0.0220 | 3+0.0250 | 11.4+0.30 | 2-M4 | 10J | 10+0.0220 | 3±0.0125 | 11.4+0.30 | 2-M4 | |||||

| 11 | 11+0.0180 | - | - | 2-M4 | 11H | 11+0.0180 | 4+0.0300 | 12.8+0.30 | 2-M4 | 11J | 11+0.0180 | 4±0.0150 | 12.8+0.30 | 2-M4 | |||||

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | |||||

| 14 | 14+0.0180 | 5+0.050+0.020 | 16+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | |||||

| 15 | 15+0.0180 | 5+0.050+0.020 | 17+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | |||||

| 16 | 16+0.0180 | 5+0.050+0.020 | 18+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | |||||

| 17 | 17+0.0180 | 5+0.050+0.020 | 19+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | |||||

| 18 | 18+0.0180 | 5+0.050+0.020 | 20+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | |||||

| 19 | 19+0.0210 | 5+0.050+0.020 | 21+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | |||||

| 20 | 20+0.0210 | 5+0.050+0.020 | 22+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | |||||

| 22 | 22+0.0210 | 7+0.061+0.025 | 25+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | |||||

| 24 | 24+0.0210 | 7+0.061+0.025 | 27+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | |||||

| 25 | 25+0.0210 | 7+0.061+0.025 | 28+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | |||||

| 28 | 28+0.0210 | 7+0.061+0.025 | 31+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | |||||

| 30 | 30+0.0210 | 7+0.061+0.025 | 33+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | |||||

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | |||||

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | |||||

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5+0.30 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3+0.30 | 2-M8 | 38J | 38+0.0250 | 10±0.0180 | 41.3+0.30 | 2-M8 | |||||

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5+0.30 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3+0.30 | 2-M8 | 40J | 40+0.0250 | 12±0.0215 | 43.3+0.30 | 2-M8 | |||||

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5+0.30 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3+0.30 | 2-M8 | 42J | 42+0.0250 | 12±0.0215 | 45.3+0.30 | 2-M8 | |||||

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5+0.30 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8+0.30 | 2-M10 | 45J | 45+0.0250 | 14±0.0215 | 48.8+0.30 | 2-M10 | |||||

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5+0.30 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8+0.30 | 2-M10 | 48J | 48+0.0250 | 14±0.0215 | 51.8+0.30 | 2-M10 | |||||

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5+0.30 | 2-M8 | 50H | 50+0.0250 | 14+0.0430 | 53.8+0.30 | 2-M10 | 50J | 50+0.0250 | 14±0.0215 | 53.8+0.30 | 2-M10 | |||||

| 55 | 55+0.0300 | 15+0.075+0.032 | 60+0.30 | 2-M10 | 55H | 55+0.0300 | 16+0.0430 | 59.3+0.30 | 2-M10 | 55J | 55+0.0300 | 16±0.0215 | 59.3+0.30 | 2-M10 | |||||

| 56 | 56+0.0300 | 15+0.075+0.032 | 61+0.30 | 2-M10 | 56H | 56+0.0300 | 16+0.0430 | 60.3+0.30 | 2-M10 | 56J | 56+0.0300 | 16±0.0215 | 60.3+0.30 | 2-M10 | |||||

| 60 | 60+0.0300 | 15+0.075+0.032 | 65+0.30 | 2-M10 | 60H | 60+0.0300 | 18+0.0430 | 64.4+0.30 | 2-M10 | 60J | 60+0.0300 | 18±0.0215 | 64.4+0.30 | 2-M10 | |||||

| 符合JIS新标准 P9 JIS B 1301 1996 | 支持电动机标准JIS C 4210 2001 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差P9 | - | - | 公差G7,F7 | 公差H9 | - | - | 8P | 8 +0.0220 | 3-0.006-0.031 | 9.4+0.30 | 2-M4 | - | - | - | - | - |

| 9P | 9 +0.0220 | 3-0.006-0.031 | 10.4+0.30 | 2-M4 | - | - | - | - | - |

| 10P | 10 +0.0220 | 3-0.006-0.031 | 11.4+0.30 | 2-M4 | - | - | - | - | - |

| 11P | 11+0.0180 | 4-0.012-0.042 | 12.8+0.30 | 2-M4 | - | - | - | - | - |

| 12P | 12 +0.0180 | 4-0.012-0.042 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14P | 14+0.0180 | 5-0.012-0.042 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15P | 15+0.0180 | 5-0.012-0.042 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16P | 16+0.0180 | 5-0.012-0.042 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17P | 17+0.0180 | 5-0.012-0.042 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18P | 18+0.0180 | 6-0.012-0.042 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19P | 19 +0.0210 | 6-0.012-0.042 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20P | 20 +0.0210 | 6-0.012-0.042 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22P | 22 +0.0210 | 6-0.012-0.042 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24P | 24 +0.0210 | 8-0.015-0.051 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25P | 25 +0.0210 | 8-0.015-0.051 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28P | 28 +0.0210 | 8-0.015-0.051 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30P | 30 +0.0210 | 8-0.015-0.051 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32P | 32 +0.0250 | 10-0.015-0.051 | 35.3+0.30 | 2-M8 | - | - | - | ||

| 35P | 35 +0.0250 | 10-0.015-0.051 | 38.3+0.30 | 2-M8 | - | - | - | - | |

| 38P | 38 +0.0250 | 10-0.015-0.051 | 41.3+0.30 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3+0.30 | 2-M8 |

| 40P | 40 +0.0250 | 12-0.018-0.061 | 43.3+0.30 | 2-M8 | - | - | - | - | - |

| 42P | 42 +0.0250 | 12-0.018-0.061 | 45.3+0.30 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3+0.30 | 2-M8 |

| 45P | 45 +0.0250 | 14-0.018-0.061 | 48.8+0.30 | 2-M10 | - | - | - | - | - |

| 48P | 48 +0.0250 | 14-0.018-0.061 | 51.8+0.30 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8+0.30 | 2-M10 |

| 50P | 50 +0.0250 | 14-0.018-0.061 | 53.8+0.30 | 2-M10 | - | - | - | - | - |

| 55P | 55 +0.0300 | 16-0.018-0.061 | 59.3+0.30 | 2-M10 | 55N | 55+0.060+0.030 | 16+0.0430 | 59.3+0.30 | 2-M10 |

| 56P | 56 +0.0300 | 16-0.018-0.061 | 60.3+0.30 | 2-M10 | - | - | - | - | - |

| 60P | 60 +0.0300 | 18-0.018-0.061 | 64.4+0.30 | 2-M10 | 60N | 60+0.060+0.030 | 18+0.0430 | 64.4+0.30 | 2-M10 |

※紧定螺钉和键槽的位置不在同一平面上。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 型号 | 从端面的位置[mm] |

|---|---|

| SFS-05 | 7 |

| SFS-06 | 9 |

| SFS-08 | 10 |

| SFS-09 | 10 |

| SFS-10 | 12 |

| SFS-12 | 12 |

| SFS-14 | 15 |

SFS-□S (C) 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 轴向弹性常数[N/mm] | 转动惯量[kg・m2] | 质量[kg] | |

|---|---|---|---|---|---|---|---|---|

| 偏角[°] | 轴向[mm] | |||||||

| SFS-05S-C | 15 | 1 | ±0.6 | 25000 | 16000 | 43 | 0.11×10-3 | 0.30 |

| SFS-06S-C | 30 | 1 | ±0.8 | 20000 | 29000 | 45 | 0.30×10-3 | 0.50 |

| SFS-08S-C | 60 | 1 | ±1.0 | 17000 | 83000 | 60 | 0.87×10-3 | 1.00 |

| SFS-09S-C | 135 | 1 | ±1.2 | 15000 | 170000 | 122 | 1.60×10-3 | 1.40 |

| SFS-10S-C | 190 | 1 | ±1.4 | 13000 | 250000 | 160 | 2.60×10-3 | 2.10 |

| SFS-12S-C | 340 | 1 | ±1.6 | 11000 | 430000 | 197 | 6.50×10-3 | 3.40 |

| SFS-14S-C | 600 | 1 | ±1.8 | 9500 | 780000 | 313 | 9.90×10-3 | 4.90 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

【尺寸】

| 型号 | d1・d2 | D | N | L | LF | S | F | K | M | |

|---|---|---|---|---|---|---|---|---|---|---|

| 最小 | 最大 | |||||||||

| SFS-05S-C | 8 | 20 | 56 | 32 | 45 | 20 | 5 | 11 | 24 | 4-M5×22 |

| SFS-06S-C | 8 | 25 | 68 | 40 | 56 | 25 | 6 | 10 | 30 | 4-M6×25 |

| SFS-08S-C | 11 | 35 | 82 | 54 | 66 | 30 | 6 | 11 | 38 | 4-M6×29 |

| SFS-09S-C | 11 | 38 | 94 | 58 | 68 | 30 | 8 | 21 | 42 | 4-M8×36 |

| SFS-10S-C | 16 | 42 | 104 | 68 | 80 | 35 | 10 | 16 | 48 | 4-M8×36 |

| SFS-12S-C | 19 | 50 | 126 | 78 | 91 | 40 | 11 | 23 | 54 | 4-M10×45 |

| SFS-14S-C | 22 | 60 | 144 | 88 | 102 | 45 | 12 | 31 | 61 | 4-M12×54 |

※ 精密配合螺栓M 公称为数量- 螺钉公称× 公称长度。

【标准孔径】

| 型号 | 标准孔径 d1・d2 [mm] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | |

| SFS-05S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFS-06S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-08S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFS-09S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFS-10S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-12S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-14S-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

※ 已有●号的栏其孔径为标准孔径。详情请参考标准孔加工规格。

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | |||||

| 公差H7,H8 | 公差E9 | - | - | 公差H7,H8 | 公差H9 | - | - | 公差H7,H8 | 公差JS9 | - | - | ||||||||

| 8 | 8+0.0220 | - | - | 2-M4 | 8H | 8+0.0220 | 3+0.0250 | 9.4+0.30 | 2-M4 | 8J | 8+0.0220 | 3±0.0125 | 9.4+0.30 | 2-M4 | |||||

| 9 | 9+0.0220 | - | - | 2-M4 | 9H | 9+0.0220 | 3+0.0250 | 10.4+0.30 | 2-M4 | 9J | 9+0.0220 | 3±0.0125 | 10.4+0.30 | 2-M4 | |||||

| 10 | 10+0.0220 | - | - | 2-M4 | 10H | 10+0.0220 | 3+0.0250 | 11.4+0.30 | 2-M4 | 10J | 10+0.0220 | 3±0.0125 | 11.4+0.30 | 2-M4 | |||||

| 11 | 11+0.0180 | - | - | 2-M4 | 11H | 11+0.0180 | 4+0.0300 | 12.8+0.30 | 2-M4 | 11J | 11+0.0180 | 4±0.0150 | 12.8+0.30 | 2-M4 | |||||

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | |||||

| 14 | 14+0.0180 | 5+0.050+0.020 | 16+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | |||||

| 15 | 15+0.0180 | 5+0.050+0.020 | 17+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | |||||

| 16 | 16+0.0180 | 5+0.050+0.020 | 18+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | |||||

| 17 | 17+0.0180 | 5+0.050+0.020 | 19+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | |||||

| 18 | 18+0.0180 | 5+0.050+0.020 | 20+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | |||||

| 19 | 19+0.0210 | 5+0.050+0.020 | 21+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | |||||

| 20 | 20+0.0210 | 5+0.050+0.020 | 22+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | |||||

| 22 | 22+0.0210 | 7+0.061+0.025 | 25+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | |||||

| 24 | 24+0.0210 | 7+0.061+0.025 | 27+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | |||||

| 25 | 25+0.0210 | 7+0.061+0.025 | 28+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | |||||

| 28 | 28+0.0210 | 7+0.061+0.025 | 31+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | |||||

| 30 | 30+0.0210 | 7+0.061+0.025 | 33+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | |||||

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | |||||

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | |||||

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5+0.30 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3+0.30 | 2-M8 | 38J | 38+0.0250 | 10±0.0180 | 41.3+0.30 | 2-M8 | |||||

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5+0.30 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3+0.30 | 2-M8 | 40J | 40+0.0250 | 12±0.0215 | 43.3+0.30 | 2-M8 | |||||

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5+0.30 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3+0.30 | 2-M8 | 42J | 42+0.0250 | 12±0.0215 | 45.3+0.30 | 2-M8 | |||||

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5+0.30 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8+0.30 | 2-M10 | 45J | 45+0.0250 | 14±0.0215 | 48.8+0.30 | 2-M10 | |||||

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5+0.30 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8+0.30 | 2-M10 | 48J | 48+0.0250 | 14±0.0215 | 51.8+0.30 | 2-M10 | |||||

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5+0.30 | 2-M8 | 50H | 50+0.0250 | 14+0.0430 | 53.8+0.30 | 2-M10 | 50J | 50+0.0250 | 14±0.0215 | 53.8+0.30 | 2-M10 | |||||

| 55 | 55+0.0300 | 15+0.075+0.032 | 60+0.30 | 2-M10 | 55H | 55+0.0300 | 16+0.0430 | 59.3+0.30 | 2-M10 | 55J | 55+0.0300 | 16±0.0215 | 59.3+0.30 | 2-M10 | |||||

| 56 | 56+0.0300 | 15+0.075+0.032 | 61+0.30 | 2-M10 | 56H | 56+0.0300 | 16+0.0430 | 60.3+0.30 | 2-M10 | 56J | 56+0.0300 | 16±0.0215 | 60.3+0.30 | 2-M10 | |||||

| 60 | 60+0.0300 | 15+0.075+0.032 | 65+0.30 | 2-M10 | 60H | 60+0.0300 | 18+0.0430 | 64.4+0.30 | 2-M10 | 60J | 60+0.0300 | 18±0.0215 | 64.4+0.30 | 2-M10 | |||||

| 符合JIS新标准 P9 JIS B 1301 1996 | 支持电动机标准JIS C 4210 2001 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差P9 | - | - | 公差G7,F7 | 公差H9 | - | - | 8P | 8 +0.0220 | 3-0.006-0.031 | 9.4+0.30 | 2-M4 | - | - | - | - | - |

| 9P | 9 +0.0220 | 3-0.006-0.031 | 10.4+0.30 | 2-M4 | - | - | - | - | - |

| 10P | 10 +0.0220 | 3-0.006-0.031 | 11.4+0.30 | 2-M4 | - | - | - | - | - |

| 11P | 11+0.0180 | 4-0.012-0.042 | 12.8+0.30 | 2-M4 | - | - | - | - | - |

| 12P | 12 +0.0180 | 4-0.012-0.042 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14P | 14+0.0180 | 5-0.012-0.042 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15P | 15+0.0180 | 5-0.012-0.042 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16P | 16+0.0180 | 5-0.012-0.042 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17P | 17+0.0180 | 5-0.012-0.042 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18P | 18+0.0180 | 6-0.012-0.042 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19P | 19 +0.0210 | 6-0.012-0.042 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20P | 20 +0.0210 | 6-0.012-0.042 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22P | 22 +0.0210 | 6-0.012-0.042 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24P | 24 +0.0210 | 8-0.015-0.051 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25P | 25 +0.0210 | 8-0.015-0.051 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28P | 28 +0.0210 | 8-0.015-0.051 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30P | 30 +0.0210 | 8-0.015-0.051 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32P | 32 +0.0250 | 10-0.015-0.051 | 35.3+0.30 | 2-M8 | - | - | - | ||

| 35P | 35 +0.0250 | 10-0.015-0.051 | 38.3+0.30 | 2-M8 | - | - | - | - | |

| 38P | 38 +0.0250 | 10-0.015-0.051 | 41.3+0.30 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3+0.30 | 2-M8 |

| 40P | 40 +0.0250 | 12-0.018-0.061 | 43.3+0.30 | 2-M8 | - | - | - | - | - |

| 42P | 42 +0.0250 | 12-0.018-0.061 | 45.3+0.30 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3+0.30 | 2-M8 |

| 45P | 45 +0.0250 | 14-0.018-0.061 | 48.8+0.30 | 2-M10 | - | - | - | - | - |

| 48P | 48 +0.0250 | 14-0.018-0.061 | 51.8+0.30 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8+0.30 | 2-M10 |

| 50P | 50 +0.0250 | 14-0.018-0.061 | 53.8+0.30 | 2-M10 | - | - | - | - | - |

| 55P | 55 +0.0300 | 16-0.018-0.061 | 59.3+0.30 | 2-M10 | 55N | 55+0.060+0.030 | 16+0.0430 | 59.3+0.30 | 2-M10 |

| 56P | 56 +0.0300 | 16-0.018-0.061 | 60.3+0.30 | 2-M10 | - | - | - | - | - |

| 60P | 60 +0.0300 | 18-0.018-0.061 | 64.4+0.30 | 2-M10 | 60N | 60+0.060+0.030 | 18+0.0430 | 64.4+0.30 | 2-M10 |

※紧定螺钉和键槽的位置不在同一平面上。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 型号 | 从端面的位置[mm] |

|---|---|

| SFS-05 | 7 |

| SFS-06 | 9 |

| SFS-08 | 10 |

| SFS-09 | 10 |

| SFS-10 | 12 |

| SFS-12 | 12 |

| SFS-14 | 15 |

SFS-□W 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 轴向弹性常数[N/mm] | 转动惯量[kg•m2] | 质量[kg] | ||

|---|---|---|---|---|---|---|---|---|---|

| 偏心[mm] | 偏角[°] | 轴向[mm] | |||||||

| SFS-05W | 20 | 0.2 | 1(单侧) | ±1.2 | 10000 | 8000 | 21 | 0.14×10-3 | 0.40 |

| SFS-06W | 40 | 0.3 | 1(单侧) | ±1.6 | 8000 | 14000 | 22 | 0.41×10-3 | 0.70 |

| SFS-08W | 80 | 0.3 | 1(单侧) | ±2.0 | 6800 | 41000 | 30 | 1.10×10-3 | 1.30 |

| SFS-09W | 180 | 0.5 | 1(单侧) | ±2.4 | 6000 | 85000 | 61 | 2.20×10-3 | 2.10 |

| SFS-10W | 250 | 0.5 | 1(单侧) | ±2.8 | 5200 | 125000 | 80 | 3.60×10-3 | 2.80 |

| SFS-12W | 450 | 0.6 | 1(单侧) | ±3.2 | 4400 | 215000 | 98 | 9.20×10-3 | 4.90 |

| SFS-14W | 800 | 0.7 | 1(单侧) | ±3.6 | 3800 | 390000 | 156 | 15.00×10-3 | 7.10 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

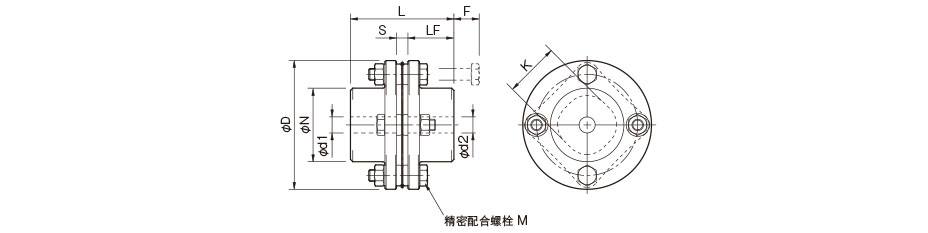

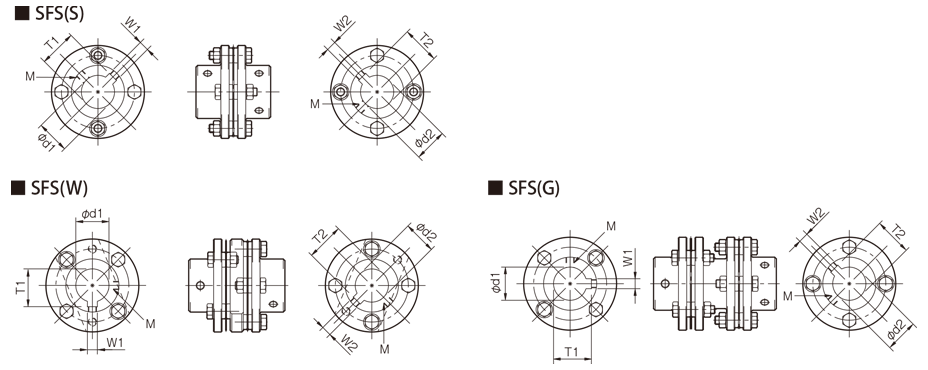

【尺寸】

| 型号 | d1, d2 | D | N | L | LF | LP | S | F | d3 | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 底孔 | 最小 | 最大 | |||||||||||

| SFS-05W | 7 | 8 | 20 | 56 | 32 | 58 | 20 | 8 | 5 | 4 | 20 | 24 | 8-M5×15 |

| SFS-06W | 7 | 8 | 25 | 68 | 40 | 74 | 25 | 12 | 6 | 3 | 24 | 30 | 8-M6×18 |

| SFS-08W | 10 | 11 | 35 | 82 | 54 | 84 | 30 | 12 | 6 | 2 | 28 | 38 | 8-M6×20 |

| SFS-09W | 10 | 11 | 38 | 94 | 58 | 98 | 30 | 22 | 8 | 12 | 32 | 42 | 8-M8×27 |

| SFS-10W | 15 | 16 | 42 | 104 | 68 | 110 | 35 | 20 | 10 | 7 | 34 | 48 | 8-M8×27 |

| SFS-12W | 18 | 19 | 50 | 126 | 78 | 127 | 40 | 25 | 11 | 10 | 40 | 54 | 8-M10×32 |

| SFS-14W | 20 | 22 | 60 | 144 | 88 | 144 | 45 | 30 | 12 | 15 | 46 | 61 | 8-M12×38 |

※底孔为钻孔。关于加工,请参阅标准孔加工规格。

※精密配合螺栓M公称为数量-螺钉公称×公称长度。

【标准孔径】

| 型号 | 标准孔径 d1・d2 [mm] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | |

| SFS-05W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFS-06W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-08W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFS-09W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFS-10W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-12W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-14W | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

※ 已有●号的栏其孔径为标准孔径。详情请参考标准孔加工规格。

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | |||||

| 公差H7,H8 | 公差E9 | - | - | 公差H7,H8 | 公差H9 | - | - | 公差H7,H8 | 公差JS9 | - | - | ||||||||

| 8 | 8+0.0220 | - | - | 2-M4 | 8H | 8+0.0220 | 3+0.0250 | 9.4+0.30 | 2-M4 | 8J | 8+0.0220 | 3±0.0125 | 9.4+0.30 | 2-M4 | |||||

| 9 | 9+0.0220 | - | - | 2-M4 | 9H | 9+0.0220 | 3+0.0250 | 10.4+0.30 | 2-M4 | 9J | 9+0.0220 | 3±0.0125 | 10.4+0.30 | 2-M4 | |||||

| 10 | 10+0.0220 | - | - | 2-M4 | 10H | 10+0.0220 | 3+0.0250 | 11.4+0.30 | 2-M4 | 10J | 10+0.0220 | 3±0.0125 | 11.4+0.30 | 2-M4 | |||||

| 11 | 11+0.0180 | - | - | 2-M4 | 11H | 11+0.0180 | 4+0.0300 | 12.8+0.30 | 2-M4 | 11J | 11+0.0180 | 4±0.0150 | 12.8+0.30 | 2-M4 | |||||

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | |||||

| 14 | 14+0.0180 | 5+0.050+0.020 | 16+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | |||||

| 15 | 15+0.0180 | 5+0.050+0.020 | 17+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | |||||

| 16 | 16+0.0180 | 5+0.050+0.020 | 18+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | |||||

| 17 | 17+0.0180 | 5+0.050+0.020 | 19+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | |||||

| 18 | 18+0.0180 | 5+0.050+0.020 | 20+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | |||||

| 19 | 19+0.0210 | 5+0.050+0.020 | 21+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | |||||

| 20 | 20+0.0210 | 5+0.050+0.020 | 22+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | |||||

| 22 | 22+0.0210 | 7+0.061+0.025 | 25+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | |||||

| 24 | 24+0.0210 | 7+0.061+0.025 | 27+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | |||||

| 25 | 25+0.0210 | 7+0.061+0.025 | 28+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | |||||

| 28 | 28+0.0210 | 7+0.061+0.025 | 31+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | |||||

| 30 | 30+0.0210 | 7+0.061+0.025 | 33+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | |||||

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | |||||

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | |||||

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5+0.30 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3+0.30 | 2-M8 | 38J | 38+0.0250 | 10±0.0180 | 41.3+0.30 | 2-M8 | |||||

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5+0.30 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3+0.30 | 2-M8 | 40J | 40+0.0250 | 12±0.0215 | 43.3+0.30 | 2-M8 | |||||

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5+0.30 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3+0.30 | 2-M8 | 42J | 42+0.0250 | 12±0.0215 | 45.3+0.30 | 2-M8 | |||||

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5+0.30 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8+0.30 | 2-M10 | 45J | 45+0.0250 | 14±0.0215 | 48.8+0.30 | 2-M10 | |||||

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5+0.30 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8+0.30 | 2-M10 | 48J | 48+0.0250 | 14±0.0215 | 51.8+0.30 | 2-M10 | |||||

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5+0.30 | 2-M8 | 50H | 50+0.0250 | 14+0.0430 | 53.8+0.30 | 2-M10 | 50J | 50+0.0250 | 14±0.0215 | 53.8+0.30 | 2-M10 | |||||

| 55 | 55+0.0300 | 15+0.075+0.032 | 60+0.30 | 2-M10 | 55H | 55+0.0300 | 16+0.0430 | 59.3+0.30 | 2-M10 | 55J | 55+0.0300 | 16±0.0215 | 59.3+0.30 | 2-M10 | |||||

| 56 | 56+0.0300 | 15+0.075+0.032 | 61+0.30 | 2-M10 | 56H | 56+0.0300 | 16+0.0430 | 60.3+0.30 | 2-M10 | 56J | 56+0.0300 | 16±0.0215 | 60.3+0.30 | 2-M10 | |||||

| 60 | 60+0.0300 | 15+0.075+0.032 | 65+0.30 | 2-M10 | 60H | 60+0.0300 | 18+0.0430 | 64.4+0.30 | 2-M10 | 60J | 60+0.0300 | 18±0.0215 | 64.4+0.30 | 2-M10 | |||||

| 符合JIS新标准 P9 JIS B 1301 1996 | 支持电动机标准JIS C 4210 2001 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差P9 | - | - | 公差G7,F7 | 公差H9 | - | - | 8P | 8 +0.0220 | 3-0.006-0.031 | 9.4+0.30 | 2-M4 | - | - | - | - | - |

| 9P | 9 +0.0220 | 3-0.006-0.031 | 10.4+0.30 | 2-M4 | - | - | - | - | - |

| 10P | 10 +0.0220 | 3-0.006-0.031 | 11.4+0.30 | 2-M4 | - | - | - | - | - |

| 11P | 11+0.0180 | 4-0.012-0.042 | 12.8+0.30 | 2-M4 | - | - | - | - | - |

| 12P | 12 +0.0180 | 4-0.012-0.042 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14P | 14+0.0180 | 5-0.012-0.042 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15P | 15+0.0180 | 5-0.012-0.042 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16P | 16+0.0180 | 5-0.012-0.042 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17P | 17+0.0180 | 5-0.012-0.042 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18P | 18+0.0180 | 6-0.012-0.042 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19P | 19 +0.0210 | 6-0.012-0.042 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20P | 20 +0.0210 | 6-0.012-0.042 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22P | 22 +0.0210 | 6-0.012-0.042 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24P | 24 +0.0210 | 8-0.015-0.051 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25P | 25 +0.0210 | 8-0.015-0.051 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28P | 28 +0.0210 | 8-0.015-0.051 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30P | 30 +0.0210 | 8-0.015-0.051 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32P | 32 +0.0250 | 10-0.015-0.051 | 35.3+0.30 | 2-M8 | - | - | - | ||

| 35P | 35 +0.0250 | 10-0.015-0.051 | 38.3+0.30 | 2-M8 | - | - | - | - | |

| 38P | 38 +0.0250 | 10-0.015-0.051 | 41.3+0.30 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3+0.30 | 2-M8 |

| 40P | 40 +0.0250 | 12-0.018-0.061 | 43.3+0.30 | 2-M8 | - | - | - | - | - |

| 42P | 42 +0.0250 | 12-0.018-0.061 | 45.3+0.30 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3+0.30 | 2-M8 |

| 45P | 45 +0.0250 | 14-0.018-0.061 | 48.8+0.30 | 2-M10 | - | - | - | - | - |

| 48P | 48 +0.0250 | 14-0.018-0.061 | 51.8+0.30 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8+0.30 | 2-M10 |

| 50P | 50 +0.0250 | 14-0.018-0.061 | 53.8+0.30 | 2-M10 | - | - | - | - | - |

| 55P | 55 +0.0300 | 16-0.018-0.061 | 59.3+0.30 | 2-M10 | 55N | 55+0.060+0.030 | 16+0.0430 | 59.3+0.30 | 2-M10 |

| 56P | 56 +0.0300 | 16-0.018-0.061 | 60.3+0.30 | 2-M10 | - | - | - | - | - |

| 60P | 60 +0.0300 | 18-0.018-0.061 | 64.4+0.30 | 2-M10 | 60N | 60+0.060+0.030 | 18+0.0430 | 64.4+0.30 | 2-M10 |

※紧定螺钉和键槽的位置不在同一平面上。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 型号 | 从端面的位置[mm] |

|---|---|

| SFS-05 | 7 |

| SFS-06 | 9 |

| SFS-08 | 10 |

| SFS-09 | 10 |

| SFS-10 | 12 |

| SFS-12 | 12 |

| SFS-14 | 15 |

SFS-□W (C) 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 轴向弹性常数[N/mm] | 转动惯量[kg•m2] | 质量[kg] | ||

|---|---|---|---|---|---|---|---|---|---|

| 偏心[mm] | 偏角[°] | 轴向[mm] | |||||||

| SFS-05W-C | 15 | 0.2 | 1(单侧) | ±1.2 | 10000 | 8000 | 21 | 0.14×10-3 | 0.40 |

| SFS-06W-C | 30 | 0.3 | 1(单侧) | ±1.6 | 8000 | 14000 | 22 | 0.41×10-3 | 0.70 |

| SFS-08W-C | 60 | 0.3 | 1(单侧) | ±2.0 | 6800 | 41000 | 30 | 1.10×10-3 | 1.30 |

| SFS-09W-C | 135 | 0.5 | 1(单侧) | ±2.4 | 6000 | 85000 | 61 | 2.20×10-3 | 2.10 |

| SFS-10W-C | 190 | 0.5 | 1(单侧) | ±2.8 | 5200 | 125000 | 80 | 3.60×10-3 | 2.80 |

| SFS-12W-C | 340 | 0.6 | 1(单侧) | ±3.2 | 4400 | 215000 | 98 | 9.20×10-3 | 4.90 |

| SFS-14W-C | 600 | 0.7 | 1(单侧) | ±3.6 | 3800 | 390000 | 156 | 15.00×10-3 | 7.10 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

【尺寸】

| 型号 | d1, d2 | D | N | L | LF | LP | S | F | d3 | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 底孔 | 最小 | 最大 | |||||||||||

| SFS-05W | 7 | 8 | 20 | 56 | 32 | 58 | 20 | 8 | 5 | 4 | 20 | 24 | 8-M5×15 |

| SFS-06W | 7 | 8 | 25 | 68 | 40 | 74 | 25 | 12 | 6 | 3 | 24 | 30 | 8-M6×18 |

| SFS-08W | 10 | 11 | 35 | 82 | 54 | 84 | 30 | 12 | 6 | 2 | 28 | 38 | 8-M6×20 |

| SFS-09W | 10 | 11 | 38 | 94 | 58 | 98 | 30 | 22 | 8 | 12 | 32 | 42 | 8-M8×27 |

| SFS-10W | 15 | 16 | 42 | 104 | 68 | 110 | 35 | 20 | 10 | 7 | 34 | 48 | 8-M8×27 |

| SFS-12W | 18 | 19 | 50 | 126 | 78 | 127 | 40 | 25 | 11 | 10 | 40 | 54 | 8-M10×32 |

| SFS-14W | 20 | 22 | 60 | 144 | 88 | 144 | 45 | 30 | 12 | 15 | 46 | 61 | 8-M12×38 |

※底孔为钻孔。关于加工,请参阅标准孔加工规格。

※精密配合螺栓M公称为数量-螺钉公称×公称长度。

【标准孔径】

| 型号 | 标准孔径 d1・d2 [mm] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | |

| SFS-05W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFS-06W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-08W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFS-09W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFS-10W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-12W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-14W-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

※ 已有●号的栏其孔径为标准孔径。详情请参考标准孔加工规格。

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | |||||

| 公差H7,H8 | 公差E9 | - | - | 公差H7,H8 | 公差H9 | - | - | 公差H7,H8 | 公差JS9 | - | - | ||||||||

| 8 | 8+0.0220 | - | - | 2-M4 | 8H | 8+0.0220 | 3+0.0250 | 9.4+0.30 | 2-M4 | 8J | 8+0.0220 | 3±0.0125 | 9.4+0.30 | 2-M4 | |||||

| 9 | 9+0.0220 | - | - | 2-M4 | 9H | 9+0.0220 | 3+0.0250 | 10.4+0.30 | 2-M4 | 9J | 9+0.0220 | 3±0.0125 | 10.4+0.30 | 2-M4 | |||||

| 10 | 10+0.0220 | - | - | 2-M4 | 10H | 10+0.0220 | 3+0.0250 | 11.4+0.30 | 2-M4 | 10J | 10+0.0220 | 3±0.0125 | 11.4+0.30 | 2-M4 | |||||

| 11 | 11+0.0180 | - | - | 2-M4 | 11H | 11+0.0180 | 4+0.0300 | 12.8+0.30 | 2-M4 | 11J | 11+0.0180 | 4±0.0150 | 12.8+0.30 | 2-M4 | |||||

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | |||||

| 14 | 14+0.0180 | 5+0.050+0.020 | 16+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | |||||

| 15 | 15+0.0180 | 5+0.050+0.020 | 17+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | |||||

| 16 | 16+0.0180 | 5+0.050+0.020 | 18+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | |||||

| 17 | 17+0.0180 | 5+0.050+0.020 | 19+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | |||||

| 18 | 18+0.0180 | 5+0.050+0.020 | 20+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | |||||

| 19 | 19+0.0210 | 5+0.050+0.020 | 21+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | |||||

| 20 | 20+0.0210 | 5+0.050+0.020 | 22+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | |||||

| 22 | 22+0.0210 | 7+0.061+0.025 | 25+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | |||||

| 24 | 24+0.0210 | 7+0.061+0.025 | 27+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | |||||

| 25 | 25+0.0210 | 7+0.061+0.025 | 28+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | |||||

| 28 | 28+0.0210 | 7+0.061+0.025 | 31+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | |||||

| 30 | 30+0.0210 | 7+0.061+0.025 | 33+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | |||||

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | |||||

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | |||||

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5+0.30 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3+0.30 | 2-M8 | 38J | 38+0.0250 | 10±0.0180 | 41.3+0.30 | 2-M8 | |||||

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5+0.30 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3+0.30 | 2-M8 | 40J | 40+0.0250 | 12±0.0215 | 43.3+0.30 | 2-M8 | |||||

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5+0.30 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3+0.30 | 2-M8 | 42J | 42+0.0250 | 12±0.0215 | 45.3+0.30 | 2-M8 | |||||

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5+0.30 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8+0.30 | 2-M10 | 45J | 45+0.0250 | 14±0.0215 | 48.8+0.30 | 2-M10 | |||||

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5+0.30 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8+0.30 | 2-M10 | 48J | 48+0.0250 | 14±0.0215 | 51.8+0.30 | 2-M10 | |||||

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5+0.30 | 2-M8 | 50H | 50+0.0250 | 14+0.0430 | 53.8+0.30 | 2-M10 | 50J | 50+0.0250 | 14±0.0215 | 53.8+0.30 | 2-M10 | |||||

| 55 | 55+0.0300 | 15+0.075+0.032 | 60+0.30 | 2-M10 | 55H | 55+0.0300 | 16+0.0430 | 59.3+0.30 | 2-M10 | 55J | 55+0.0300 | 16±0.0215 | 59.3+0.30 | 2-M10 | |||||

| 56 | 56+0.0300 | 15+0.075+0.032 | 61+0.30 | 2-M10 | 56H | 56+0.0300 | 16+0.0430 | 60.3+0.30 | 2-M10 | 56J | 56+0.0300 | 16±0.0215 | 60.3+0.30 | 2-M10 | |||||

| 60 | 60+0.0300 | 15+0.075+0.032 | 65+0.30 | 2-M10 | 60H | 60+0.0300 | 18+0.0430 | 64.4+0.30 | 2-M10 | 60J | 60+0.0300 | 18±0.0215 | 64.4+0.30 | 2-M10 | |||||

| 符合JIS新标准 P9 JIS B 1301 1996 | 支持电动机标准JIS C 4210 2001 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差P9 | - | - | 公差G7,F7 | 公差H9 | - | - | 8P | 8 +0.0220 | 3-0.006-0.031 | 9.4+0.30 | 2-M4 | - | - | - | - | - |

| 9P | 9 +0.0220 | 3-0.006-0.031 | 10.4+0.30 | 2-M4 | - | - | - | - | - |

| 10P | 10 +0.0220 | 3-0.006-0.031 | 11.4+0.30 | 2-M4 | - | - | - | - | - |

| 11P | 11+0.0180 | 4-0.012-0.042 | 12.8+0.30 | 2-M4 | - | - | - | - | - |

| 12P | 12 +0.0180 | 4-0.012-0.042 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14P | 14+0.0180 | 5-0.012-0.042 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15P | 15+0.0180 | 5-0.012-0.042 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16P | 16+0.0180 | 5-0.012-0.042 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17P | 17+0.0180 | 5-0.012-0.042 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18P | 18+0.0180 | 6-0.012-0.042 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19P | 19 +0.0210 | 6-0.012-0.042 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20P | 20 +0.0210 | 6-0.012-0.042 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22P | 22 +0.0210 | 6-0.012-0.042 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24P | 24 +0.0210 | 8-0.015-0.051 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25P | 25 +0.0210 | 8-0.015-0.051 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28P | 28 +0.0210 | 8-0.015-0.051 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30P | 30 +0.0210 | 8-0.015-0.051 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32P | 32 +0.0250 | 10-0.015-0.051 | 35.3+0.30 | 2-M8 | - | - | - | ||

| 35P | 35 +0.0250 | 10-0.015-0.051 | 38.3+0.30 | 2-M8 | - | - | - | - | |

| 38P | 38 +0.0250 | 10-0.015-0.051 | 41.3+0.30 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3+0.30 | 2-M8 |

| 40P | 40 +0.0250 | 12-0.018-0.061 | 43.3+0.30 | 2-M8 | - | - | - | - | - |

| 42P | 42 +0.0250 | 12-0.018-0.061 | 45.3+0.30 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3+0.30 | 2-M8 |

| 45P | 45 +0.0250 | 14-0.018-0.061 | 48.8+0.30 | 2-M10 | - | - | - | - | - |

| 48P | 48 +0.0250 | 14-0.018-0.061 | 51.8+0.30 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8+0.30 | 2-M10 |

| 50P | 50 +0.0250 | 14-0.018-0.061 | 53.8+0.30 | 2-M10 | - | - | - | - | - |

| 55P | 55 +0.0300 | 16-0.018-0.061 | 59.3+0.30 | 2-M10 | 55N | 55+0.060+0.030 | 16+0.0430 | 59.3+0.30 | 2-M10 |

| 56P | 56 +0.0300 | 16-0.018-0.061 | 60.3+0.30 | 2-M10 | - | - | - | - | - |

| 60P | 60 +0.0300 | 18-0.018-0.061 | 64.4+0.30 | 2-M10 | 60N | 60+0.060+0.030 | 18+0.0430 | 64.4+0.30 | 2-M10 |

※紧定螺钉和键槽的位置不在同一平面上。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 型号 | 从端面的位置[mm] |

|---|---|

| SFS-05 | 7 |

| SFS-06 | 9 |

| SFS-08 | 10 |

| SFS-09 | 10 |

| SFS-10 | 12 |

| SFS-12 | 12 |

| SFS-14 | 15 |

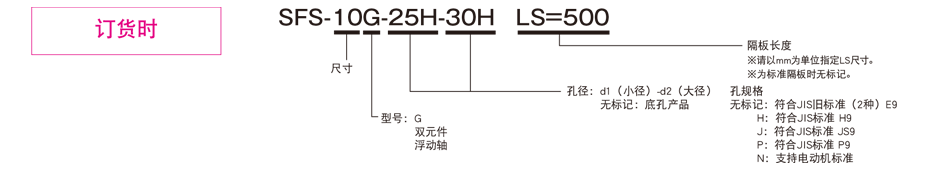

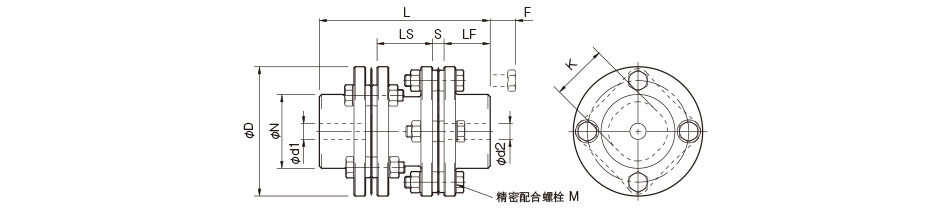

SFS-□G 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 轴向弹性常数[N/mm] | 转动惯量[kg•m2] | 质量[kg] | ||

|---|---|---|---|---|---|---|---|---|---|

| 偏心[mm] | 偏角[°] | 轴向[mm] | |||||||

| SFS-05G | 20 | 0.5 | 1(单侧) | ±1.2 | 20000 | 8000 | 21 | 0.20×10-3 | 0.50 |

| SFS-06G | 40 | 0.5 | 1(单侧) | ±1.6 | 16000 | 14000 | 22 | 0.55×10-3 | 0.90 |

| SFS-08G | 80 | 0.5 | 1(单侧) | ±2.0 | 13000 | 41000 | 30 | 1.50×10-3 | 1.70 |

| SFS-09G | 180 | 0.6 | 1(单侧) | ±2.4 | 12000 | 85000 | 61 | 2.90×10-3 | 2.40 |

| SFS-10G | 250 | 0.6 | 1(单侧) | ±2.8 | 10000 | 125000 | 80 | 4.60×10-3 | 3.30 |

| SFS-12G | 450 | 0.8 | 1(单侧) | ±3.2 | 8000 | 215000 | 98 | 11.80×10-3 | 5.80 |

| SFS-14G | 800 | 0.9 | 1(单侧) | ±3.6 | 7000 | 390000 | 156 | 21.20×10-3 | 8.60 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

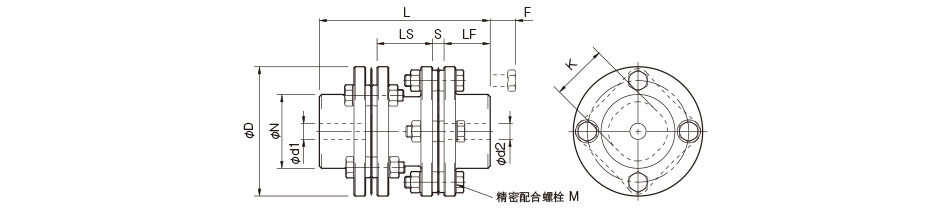

【尺寸】

| 型号 | d1, d2 | D | N | L | LF | LS | S | F | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 底孔 | 最小 | 最大 | ||||||||||

| SFS-05G | 7 | 8 | 20 | 56 | 32 | 74 | 20 | 24 | 5 | 11 | 24 | 8-M5×22 |

| SFS-06G | 7 | 8 | 25 | 68 | 40 | 86 | 25 | 24 | 6 | 10 | 30 | 8-M6×25 |

| SFS-08G | 10 | 11 | 35 | 82 | 54 | 98 | 30 | 26 | 6 | 11 | 38 | 8-M6×29 |

| SFS-09G | 10 | 11 | 38 | 94 | 58 | 106 | 30 | 30 | 8 | 21 | 42 | 8-M8×36 |

| SFS-10G | 15 | 16 | 42 | 104 | 68 | 120 | 35 | 30 | 10 | 16 | 48 | 8-M8×36 |

| SFS-12G | 18 | 19 | 50 | 126 | 78 | 140 | 40 | 38 | 11 | 23 | 54 | 8-M10×45 |

| SFS-14G | 20 | 22 | 60 | 144 | 88 | 160 | 45 | 46 | 12 | 31 | 61 | 8-M12×54 |

※底孔为钻孔。

※需要上述LS 尺寸以外的产品时, 请指定所需的LS 尺寸[mm]。另外,上述LS 尺寸未满、LS ≧ 1000 时请洽询。

※精密配合螺栓M公称为数量-螺钉公称×公称长度。

【标准孔径】

| 型号 | 标准孔径 d1・d2 [mm]] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | |

| SFS-05G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFS-06G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-08G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFS-09G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFS-10G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-12G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-14G | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

※ 已有●号的栏其孔径为标准孔径。详情请参考标准孔加工规格。

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | |||||

| 公差H7,H8 | 公差E9 | - | - | 公差H7,H8 | 公差H9 | - | - | 公差H7,H8 | 公差JS9 | - | - | ||||||||

| 8 | 8+0.0220 | - | - | 2-M4 | 8H | 8+0.0220 | 3+0.0250 | 9.4+0.30 | 2-M4 | 8J | 8+0.0220 | 3±0.0125 | 9.4+0.30 | 2-M4 | |||||

| 9 | 9+0.0220 | - | - | 2-M4 | 9H | 9+0.0220 | 3+0.0250 | 10.4+0.30 | 2-M4 | 9J | 9+0.0220 | 3±0.0125 | 10.4+0.30 | 2-M4 | |||||

| 10 | 10+0.0220 | - | - | 2-M4 | 10H | 10+0.0220 | 3+0.0250 | 11.4+0.30 | 2-M4 | 10J | 10+0.0220 | 3±0.0125 | 11.4+0.30 | 2-M4 | |||||

| 11 | 11+0.0180 | - | - | 2-M4 | 11H | 11+0.0180 | 4+0.0300 | 12.8+0.30 | 2-M4 | 11J | 11+0.0180 | 4±0.0150 | 12.8+0.30 | 2-M4 | |||||

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | |||||

| 14 | 14+0.0180 | 5+0.050+0.020 | 16+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | |||||

| 15 | 15+0.0180 | 5+0.050+0.020 | 17+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | |||||

| 16 | 16+0.0180 | 5+0.050+0.020 | 18+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | |||||

| 17 | 17+0.0180 | 5+0.050+0.020 | 19+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | |||||

| 18 | 18+0.0180 | 5+0.050+0.020 | 20+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | |||||

| 19 | 19+0.0210 | 5+0.050+0.020 | 21+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | |||||

| 20 | 20+0.0210 | 5+0.050+0.020 | 22+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | |||||

| 22 | 22+0.0210 | 7+0.061+0.025 | 25+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | |||||

| 24 | 24+0.0210 | 7+0.061+0.025 | 27+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | |||||

| 25 | 25+0.0210 | 7+0.061+0.025 | 28+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | |||||

| 28 | 28+0.0210 | 7+0.061+0.025 | 31+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | |||||

| 30 | 30+0.0210 | 7+0.061+0.025 | 33+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | |||||

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | |||||

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | |||||

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5+0.30 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3+0.30 | 2-M8 | 38J | 38+0.0250 | 10±0.0180 | 41.3+0.30 | 2-M8 | |||||

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5+0.30 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3+0.30 | 2-M8 | 40J | 40+0.0250 | 12±0.0215 | 43.3+0.30 | 2-M8 | |||||

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5+0.30 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3+0.30 | 2-M8 | 42J | 42+0.0250 | 12±0.0215 | 45.3+0.30 | 2-M8 | |||||

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5+0.30 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8+0.30 | 2-M10 | 45J | 45+0.0250 | 14±0.0215 | 48.8+0.30 | 2-M10 | |||||

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5+0.30 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8+0.30 | 2-M10 | 48J | 48+0.0250 | 14±0.0215 | 51.8+0.30 | 2-M10 | |||||

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5+0.30 | 2-M8 | 50H | 50+0.0250 | 14+0.0430 | 53.8+0.30 | 2-M10 | 50J | 50+0.0250 | 14±0.0215 | 53.8+0.30 | 2-M10 | |||||

| 55 | 55+0.0300 | 15+0.075+0.032 | 60+0.30 | 2-M10 | 55H | 55+0.0300 | 16+0.0430 | 59.3+0.30 | 2-M10 | 55J | 55+0.0300 | 16±0.0215 | 59.3+0.30 | 2-M10 | |||||

| 56 | 56+0.0300 | 15+0.075+0.032 | 61+0.30 | 2-M10 | 56H | 56+0.0300 | 16+0.0430 | 60.3+0.30 | 2-M10 | 56J | 56+0.0300 | 16±0.0215 | 60.3+0.30 | 2-M10 | |||||

| 60 | 60+0.0300 | 15+0.075+0.032 | 65+0.30 | 2-M10 | 60H | 60+0.0300 | 18+0.0430 | 64.4+0.30 | 2-M10 | 60J | 60+0.0300 | 18±0.0215 | 64.4+0.30 | 2-M10 | |||||

| 符合JIS新标准 P9 JIS B 1301 1996 | 支持电动机标准JIS C 4210 2001 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差P9 | - | - | 公差G7,F7 | 公差H9 | - | - | 8P | 8 +0.0220 | 3-0.006-0.031 | 9.4+0.30 | 2-M4 | - | - | - | - | - |

| 9P | 9 +0.0220 | 3-0.006-0.031 | 10.4+0.30 | 2-M4 | - | - | - | - | - |

| 10P | 10 +0.0220 | 3-0.006-0.031 | 11.4+0.30 | 2-M4 | - | - | - | - | - |

| 11P | 11+0.0180 | 4-0.012-0.042 | 12.8+0.30 | 2-M4 | - | - | - | - | - |

| 12P | 12 +0.0180 | 4-0.012-0.042 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14P | 14+0.0180 | 5-0.012-0.042 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15P | 15+0.0180 | 5-0.012-0.042 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16P | 16+0.0180 | 5-0.012-0.042 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17P | 17+0.0180 | 5-0.012-0.042 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18P | 18+0.0180 | 6-0.012-0.042 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19P | 19 +0.0210 | 6-0.012-0.042 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20P | 20 +0.0210 | 6-0.012-0.042 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22P | 22 +0.0210 | 6-0.012-0.042 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24P | 24 +0.0210 | 8-0.015-0.051 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25P | 25 +0.0210 | 8-0.015-0.051 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28P | 28 +0.0210 | 8-0.015-0.051 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30P | 30 +0.0210 | 8-0.015-0.051 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32P | 32 +0.0250 | 10-0.015-0.051 | 35.3+0.30 | 2-M8 | - | - | - | ||

| 35P | 35 +0.0250 | 10-0.015-0.051 | 38.3+0.30 | 2-M8 | - | - | - | - | |

| 38P | 38 +0.0250 | 10-0.015-0.051 | 41.3+0.30 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3+0.30 | 2-M8 |

| 40P | 40 +0.0250 | 12-0.018-0.061 | 43.3+0.30 | 2-M8 | - | - | - | - | - |

| 42P | 42 +0.0250 | 12-0.018-0.061 | 45.3+0.30 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3+0.30 | 2-M8 |

| 45P | 45 +0.0250 | 14-0.018-0.061 | 48.8+0.30 | 2-M10 | - | - | - | - | - |

| 48P | 48 +0.0250 | 14-0.018-0.061 | 51.8+0.30 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8+0.30 | 2-M10 |

| 50P | 50 +0.0250 | 14-0.018-0.061 | 53.8+0.30 | 2-M10 | - | - | - | - | - |

| 55P | 55 +0.0300 | 16-0.018-0.061 | 59.3+0.30 | 2-M10 | 55N | 55+0.060+0.030 | 16+0.0430 | 59.3+0.30 | 2-M10 |

| 56P | 56 +0.0300 | 16-0.018-0.061 | 60.3+0.30 | 2-M10 | - | - | - | - | - |

| 60P | 60 +0.0300 | 18-0.018-0.061 | 64.4+0.30 | 2-M10 | 60N | 60+0.060+0.030 | 18+0.0430 | 64.4+0.30 | 2-M10 |

※紧定螺钉和键槽的位置不在同一平面上。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 型号 | 从端面的位置[mm] |

|---|---|

| SFS-05 | 7 |

| SFS-06 | 9 |

| SFS-08 | 10 |

| SFS-09 | 10 |

| SFS-10 | 12 |

| SFS-12 | 12 |

| SFS-14 | 15 |

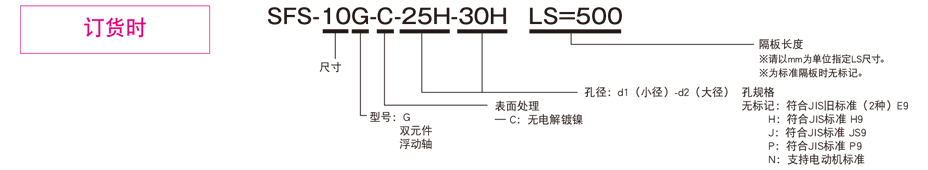

SFS-□G (C) 型

【规格】

| 型号 | 允许转矩[N•m] | 允许误差 | 最高转速[min-1] | 扭转弹性常数[N•m/rad] | 轴向弹性常数[N/mm] | 转动惯量[kg•m2] | 质量[kg] | ||

|---|---|---|---|---|---|---|---|---|---|

| 偏心[mm] | 偏角[°] | 轴向[mm] | |||||||

| SFS-05G-C | 15 | 0.5 | 1(单侧) | ±1.2 | 20000 | 8000 | 21 | 0.20×10-3 | 0.50 |

| SFS-06G-C | 30 | 0.5 | 1(单侧) | ±1.6 | 16000 | 14000 | 22 | 0.55×10-3 | 0.90 |

| SFS-08G-C | 60 | 0.5 | 1(单侧) | ±2.0 | 13000 | 41000 | 30 | 1.50×10-3 | 1.70 |

| SFS-09G-C | 135 | 0.6 | 1(单侧) | ±2.4 | 12000 | 85000 | 61 | 2.90×10-3 | 2.40 |

| SFS-10G-C | 190 | 0.6 | 1(单侧) | ±2.8 | 10000 | 125000 | 80 | 4.60×10-3 | 3.30 |

| SFS-12G-C | 340 | 0.8 | 1(单侧) | ±3.2 | 8000 | 215000 | 98 | 11.80×10-3 | 5.80 |

| SFS-14G-C | 600 | 0.9 | 1(单侧) | ±3.6 | 7000 | 390000 | 156 | 21.20×10-3 | 8.60 |

※最高转速未考虑动平衡。

※转动惯量及质量为最大孔径时的数值。

【尺寸】

| 型号 | d1・d2 | D | N | L | LF | LS | S | F | K | M | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 下穴 | 最小 | 最大 | ||||||||||

| SFS-05G-C | 7 | 8 | 20 | 56 | 32 | 74 | 20 | 24 | 5 | 11 | 24 | 8-M5×22 |

| SFS-06G-C | 7 | 8 | 25 | 68 | 40 | 86 | 25 | 24 | 6 | 10 | 30 | 8-M6×25 |

| SFS-08G-C | 10 | 11 | 35 | 82 | 54 | 98 | 30 | 26 | 6 | 11 | 38 | 8-M6×29 |

| SFS-09G-C | 10 | 11 | 38 | 94 | 58 | 106 | 30 | 30 | 8 | 21 | 42 | 8-M8×36 |

| SFS-10G-C | 15 | 16 | 42 | 104 | 68 | 120 | 35 | 30 | 10 | 16 | 48 | 8-M8×36 |

| SFS-12G-C | 18 | 19 | 50 | 126 | 78 | 140 | 40 | 38 | 11 | 23 | 54 | 8-M10×45 |

| SFS-14G-C | 20 | 22 | 60 | 144 | 88 | 160 | 45 | 46 | 12 | 31 | 61 | 8-M12×54 |

※需要上述LS 尺寸以外的产品时, 请指定所需的LS 尺寸[mm]。另外,上述LS 尺寸未满、LS ≧ 1000 时请洽询。

※无电解镀镍(SFS- □ G-C)规格的LS 长度超过100mm 时,轴插入的长度不得超过LF 的长度。请注意。

※精密配合螺栓M 公称为数量- 螺钉公称× 公称长度。

【标准孔径】

| 型号 | 标准孔径 d1・d2 [mm] | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 9 | 10 | 11 | 12 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 56 | 60 | |

| SFS-05G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||||||

| SFS-06G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-08G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

| SFS-09G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||

| SFS-10G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-12G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| SFS-14G-C | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||||

※ 已有●号的栏其孔径为标准孔径。详情请参考标准孔加工规格。

【标准孔加工规格】

| 符合JIS旧标准 2 种 JIS B 1301 1959 | 符合JIS新标准 H9 JIS B 1301 1996 | 符合JIS新标准 JS9 JIS B 1301 1996 | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔径公称 | 孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | |||||

| 公差H7,H8 | 公差E9 | - | - | 公差H7,H8 | 公差H9 | - | - | 公差H7,H8 | 公差JS9 | - | - | ||||||||

| 8 | 8+0.0220 | - | - | 2-M4 | 8H | 8+0.0220 | 3+0.0250 | 9.4+0.30 | 2-M4 | 8J | 8+0.0220 | 3±0.0125 | 9.4+0.30 | 2-M4 | |||||

| 9 | 9+0.0220 | - | - | 2-M4 | 9H | 9+0.0220 | 3+0.0250 | 10.4+0.30 | 2-M4 | 9J | 9+0.0220 | 3±0.0125 | 10.4+0.30 | 2-M4 | |||||

| 10 | 10+0.0220 | - | - | 2-M4 | 10H | 10+0.0220 | 3+0.0250 | 11.4+0.30 | 2-M4 | 10J | 10+0.0220 | 3±0.0125 | 11.4+0.30 | 2-M4 | |||||

| 11 | 11+0.0180 | - | - | 2-M4 | 11H | 11+0.0180 | 4+0.0300 | 12.8+0.30 | 2-M4 | 11J | 11+0.0180 | 4±0.0150 | 12.8+0.30 | 2-M4 | |||||

| 12 | 12+0.0180 | 4+0.050+0.020 | 13.5+0.30 | 2-M4 | 12H | 12+0.0180 | 4+0.0300 | 13.8+0.30 | 2-M4 | 12J | 12+0.0180 | 4±0.0150 | 13.8+0.30 | 2-M4 | |||||

| 14 | 14+0.0180 | 5+0.050+0.020 | 16+0.30 | 2-M4 | 14H | 14+0.0180 | 5+0.0300 | 16.3+0.30 | 2-M4 | 14J | 14+0.0180 | 5±0.0150 | 16.3+0.30 | 2-M4 | |||||

| 15 | 15+0.0180 | 5+0.050+0.020 | 17+0.30 | 2-M4 | 15H | 15+0.0180 | 5+0.0300 | 17.3+0.30 | 2-M4 | 15J | 15+0.0180 | 5±0.0150 | 17.3+0.30 | 2-M4 | |||||

| 16 | 16+0.0180 | 5+0.050+0.020 | 18+0.30 | 2-M4 | 16H | 16+0.0180 | 5+0.0300 | 18.3+0.30 | 2-M4 | 16J | 16+0.0180 | 5±0.0150 | 18.3+0.30 | 2-M4 | |||||

| 17 | 17+0.0180 | 5+0.050+0.020 | 19+0.30 | 2-M4 | 17H | 17+0.0180 | 5+0.0300 | 19.3+0.30 | 2-M4 | 17J | 17+0.0180 | 5±0.0150 | 19.3+0.30 | 2-M4 | |||||

| 18 | 18+0.0180 | 5+0.050+0.020 | 20+0.30 | 2-M4 | 18H | 18+0.0180 | 6+0.0300 | 20.8+0.30 | 2-M5 | 18J | 18+0.0180 | 6±0.0150 | 20.8+0.30 | 2-M5 | |||||

| 19 | 19+0.0210 | 5+0.050+0.020 | 21+0.30 | 2-M4 | 19H | 19+0.0210 | 6+0.0300 | 21.8+0.30 | 2-M5 | 19J | 19+0.0210 | 6±0.0150 | 21.8+0.30 | 2-M5 | |||||

| 20 | 20+0.0210 | 5+0.050+0.020 | 22+0.30 | 2-M4 | 20H | 20+0.0210 | 6+0.0300 | 22.8+0.30 | 2-M5 | 20J | 20+0.0210 | 6±0.0150 | 22.8+0.30 | 2-M5 | |||||

| 22 | 22+0.0210 | 7+0.061+0.025 | 25+0.30 | 2-M6 | 22H | 22+0.0210 | 6+0.0300 | 24.8+0.30 | 2-M5 | 22J | 22+0.0210 | 6±0.0150 | 24.8+0.30 | 2-M5 | |||||

| 24 | 24+0.0210 | 7+0.061+0.025 | 27+0.30 | 2-M6 | 24H | 24+0.0210 | 8+0.0360 | 27.3+0.30 | 2-M6 | 24J | 24+0.0210 | 8±0.0180 | 27.3+0.30 | 2-M6 | |||||

| 25 | 25+0.0210 | 7+0.061+0.025 | 28+0.30 | 2-M6 | 25H | 25+0.0210 | 8+0.0360 | 28.3+0.30 | 2-M6 | 25J | 25+0.0210 | 8±0.0180 | 28.3+0.30 | 2-M6 | |||||

| 28 | 28+0.0210 | 7+0.061+0.025 | 31+0.30 | 2-M6 | 28H | 28+0.0210 | 8+0.0360 | 31.3+0.30 | 2-M6 | 28J | 28+0.0210 | 8±0.0180 | 31.3+0.30 | 2-M6 | |||||

| 30 | 30+0.0210 | 7+0.061+0.025 | 33+0.30 | 2-M6 | 30H | 30+0.0210 | 8+0.0360 | 33.3+0.30 | 2-M6 | 30J | 30+0.0210 | 8±0.0180 | 33.3+0.30 | 2-M6 | |||||

| 32 | 32+0.0250 | 10+0.061+0.025 | 35.5+0.30 | 2-M8 | 32H | 32+0.0250 | 10+0.0360 | 35.3+0.30 | 2-M8 | 32J | 32+0.0250 | 10±0.0180 | 35.3+0.30 | 2-M8 | |||||

| 35 | 35+0.0250 | 10+0.061+0.025 | 38.5+0.30 | 2-M8 | 35H | 35+0.0250 | 10+0.0360 | 38.3+0.30 | 2-M8 | 35J | 35+0.0250 | 10±0.0180 | 38.3+0.30 | 2-M8 | |||||

| 38 | 38+0.0250 | 10+0.061+0.025 | 41.5+0.30 | 2-M8 | 38H | 38+0.0250 | 10+0.0360 | 41.3+0.30 | 2-M8 | 38J | 38+0.0250 | 10±0.0180 | 41.3+0.30 | 2-M8 | |||||

| 40 | 40+0.0250 | 10+0.061+0.025 | 43.5+0.30 | 2-M8 | 40H | 40+0.0250 | 12+0.0430 | 43.3+0.30 | 2-M8 | 40J | 40+0.0250 | 12±0.0215 | 43.3+0.30 | 2-M8 | |||||

| 42 | 42+0.0250 | 12+0.075+0.032 | 45.5+0.30 | 2-M8 | 42H | 42+0.0250 | 12+0.0430 | 45.3+0.30 | 2-M8 | 42J | 42+0.0250 | 12±0.0215 | 45.3+0.30 | 2-M8 | |||||

| 45 | 45+0.0250 | 12+0.075+0.032 | 48.5+0.30 | 2-M8 | 45H | 45+0.0250 | 14+0.0430 | 48.8+0.30 | 2-M10 | 45J | 45+0.0250 | 14±0.0215 | 48.8+0.30 | 2-M10 | |||||

| 48 | 48+0.0250 | 12+0.075+0.032 | 51.5+0.30 | 2-M8 | 48H | 48+0.0250 | 14+0.0430 | 51.8+0.30 | 2-M10 | 48J | 48+0.0250 | 14±0.0215 | 51.8+0.30 | 2-M10 | |||||

| 50 | 50+0.0250 | 12+0.075+0.032 | 53.5+0.30 | 2-M8 | 50H | 50+0.0250 | 14+0.0430 | 53.8+0.30 | 2-M10 | 50J | 50+0.0250 | 14±0.0215 | 53.8+0.30 | 2-M10 | |||||

| 55 | 55+0.0300 | 15+0.075+0.032 | 60+0.30 | 2-M10 | 55H | 55+0.0300 | 16+0.0430 | 59.3+0.30 | 2-M10 | 55J | 55+0.0300 | 16±0.0215 | 59.3+0.30 | 2-M10 | |||||

| 56 | 56+0.0300 | 15+0.075+0.032 | 61+0.30 | 2-M10 | 56H | 56+0.0300 | 16+0.0430 | 60.3+0.30 | 2-M10 | 56J | 56+0.0300 | 16±0.0215 | 60.3+0.30 | 2-M10 | |||||

| 60 | 60+0.0300 | 15+0.075+0.032 | 65+0.30 | 2-M10 | 60H | 60+0.0300 | 18+0.0430 | 64.4+0.30 | 2-M10 | 60J | 60+0.0300 | 18±0.0215 | 64.4+0.30 | 2-M10 | |||||

| 符合JIS新标准 P9 JIS B 1301 1996 | 支持电动机标准JIS C 4210 2001 | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) | 孔 径 公 称 |

孔径(d1・d2) | 键槽宽度(W1・W2) | 键槽高度(T1・T2) | 紧定螺钉孔(M) |

| 公差H7,H8 | 公差P9 | - | - | 公差G7,F7 | 公差H9 | - | - | 8P | 8 +0.0220 | 3-0.006-0.031 | 9.4+0.30 | 2-M4 | - | - | - | - | - |

| 9P | 9 +0.0220 | 3-0.006-0.031 | 10.4+0.30 | 2-M4 | - | - | - | - | - |

| 10P | 10 +0.0220 | 3-0.006-0.031 | 11.4+0.30 | 2-M4 | - | - | - | - | - |

| 11P | 11+0.0180 | 4-0.012-0.042 | 12.8+0.30 | 2-M4 | - | - | - | - | - |

| 12P | 12 +0.0180 | 4-0.012-0.042 | 13.8+0.30 | 2-M4 | - | - | - | - | - |

| 14P | 14+0.0180 | 5-0.012-0.042 | 16.3+0.30 | 2-M4 | 14N | 14+0.024+0.006 | 5+0.0300 | 16.3+0.30 | 2-M4 |

| 15P | 15+0.0180 | 5-0.012-0.042 | 17.3+0.30 | 2-M4 | - | - | - | - | - |

| 16P | 16+0.0180 | 5-0.012-0.042 | 18.3+0.30 | 2-M4 | - | - | - | - | - |

| 17P | 17+0.0180 | 5-0.012-0.042 | 19.3+0.30 | 2-M4 | - | - | - | - | - |

| 18P | 18+0.0180 | 6-0.012-0.042 | 20.8+0.30 | 2-M5 | - | - | - | - | - |

| 19P | 19 +0.0210 | 6-0.012-0.042 | 21.8+0.30 | 2-M5 | 19N | 19+0.028+0.007 | 6+0.0300 | 21.8+0.30 | 2-M5 |

| 20P | 20 +0.0210 | 6-0.012-0.042 | 22.8+0.30 | 2-M5 | - | - | - | - | - |

| 22P | 22 +0.0210 | 6-0.012-0.042 | 24.8+0.30 | 2-M5 | - | - | - | - | - |

| 24P | 24 +0.0210 | 8-0.015-0.051 | 27.3+0.30 | 2-M6 | 24N | 24+0.028+0.007 | 8+0.0360 | 27.3+0.30 | 2-M6 |

| 25P | 25 +0.0210 | 8-0.015-0.051 | 28.3+0.30 | 2-M6 | - | - | - | - | - |

| 28P | 28 +0.0210 | 8-0.015-0.051 | 31.3+0.30 | 2-M6 | 28N | 28+0.028+0.007 | 8+0.0360 | 31.3+0.30 | 2-M6 |

| 30P | 30 +0.0210 | 8-0.015-0.051 | 33.3+0.30 | 2-M6 | - | - | - | - | - |

| 32P | 32 +0.0250 | 10-0.015-0.051 | 35.3+0.30 | 2-M8 | - | - | - | ||

| 35P | 35 +0.0250 | 10-0.015-0.051 | 38.3+0.30 | 2-M8 | - | - | - | - | |

| 38P | 38 +0.0250 | 10-0.015-0.051 | 41.3+0.30 | 2-M8 | 38N | 38+0.050+0.025 | 10+0.0360 | 41.3+0.30 | 2-M8 |

| 40P | 40 +0.0250 | 12-0.018-0.061 | 43.3+0.30 | 2-M8 | - | - | - | - | - |

| 42P | 42 +0.0250 | 12-0.018-0.061 | 45.3+0.30 | 2-M8 | 42N | 42+0.050+0.025 | 12+0.0430 | 45.3+0.30 | 2-M8 |

| 45P | 45 +0.0250 | 14-0.018-0.061 | 48.8+0.30 | 2-M10 | - | - | - | - | - |

| 48P | 48 +0.0250 | 14-0.018-0.061 | 51.8+0.30 | 2-M10 | 48N | 48+0.050+0.025 | 14+0.0430 | 51.8+0.30 | 2-M10 |

| 50P | 50 +0.0250 | 14-0.018-0.061 | 53.8+0.30 | 2-M10 | - | - | - | - | - |

| 55P | 55 +0.0300 | 16-0.018-0.061 | 59.3+0.30 | 2-M10 | 55N | 55+0.060+0.030 | 16+0.0430 | 59.3+0.30 | 2-M10 |

| 56P | 56 +0.0300 | 16-0.018-0.061 | 60.3+0.30 | 2-M10 | - | - | - | - | - |

| 60P | 60 +0.0300 | 18-0.018-0.061 | 64.4+0.30 | 2-M10 | 60N | 60+0.060+0.030 | 18+0.0430 | 64.4+0.30 | 2-M10 |

※紧定螺钉和键槽的位置不在同一平面上。

※紧定螺钉为产品附带。

※键槽加工的位置精度采用目视。

※如对键槽相对于各毂的位置精度有要求,请向本公司洽询。

※有关标明以外的孔加工标准尺寸,请参阅卷末的技术资料。

【紧定螺钉的位置】

| 型号 | 从端面的位置[mm] |

|---|---|

| SFS-05 | 7 |

| SFS-06 | 9 |

| SFS-08 | 10 |

| SFS-09 | 10 |

| SFS-10 | 12 |

| SFS-12 | 12 |

| SFS-14 | 15 |