What is a coupling (shaft coupling)?

Types and Features.

Last Modified:2017/02/27

-

Index

- What is a coupling (shaft coupling)?

- The type and features of couplings

How does a coupling work? You will know here why it is necessary.

You can learn about the type and features of couplings. A table useful for selection is posted.

What is a coupling (shaft coupling)?

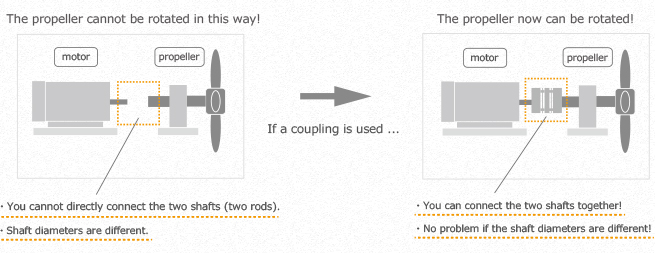

A coupling is a mechanical element part that connects two shafts together to accurately transmit the power from the drive side to the driven side while absorbing the mounting error (misalignment), etc. of the two shafts.

Coupling in the machine industry is interpreted as "a part that connects two shafts together", and is generally called "coupling", "shaft coupling" or "joint".

Power can be transmitted by using a coupling, even between axes of different diameters as shown in the following figures.

-

The role of a coupling (shaft fitting)

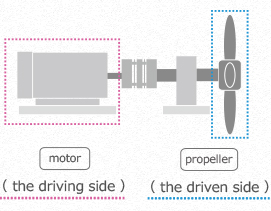

- 1.Power is transmitted from the driving side (turning side) to the driven side

(turned side). - 2.Absorbs mounting errors between the axes of the driving side (turning side)

and the driven side (turning side). - 3.Absorbs vibration from the driving side (turning side) and protects

surrounding products. - 4.Does not transfer heat from the motor on the drive side (turning side), etc.

to the driven side (turned side).

The role of a coupling is mainly as follows.

1.Transmit power

The primary reason for using a coupling is to connect the drive shaft to the driven shaft.

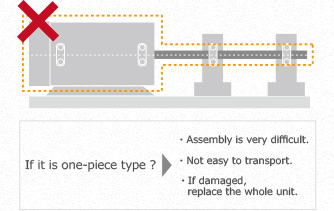

It is difficult to manufacture a machine connected with one-piece shaft instead of using a coupling. It creates problems in terms of cost and accuracy, but also transportation and assembly are very difficult, so it takes extra man-hour.

Also, in the case of one-piece shaft, it must be replaced in its entirety, if either the drive side or the driven side is broken.

2.Absorb misalignment

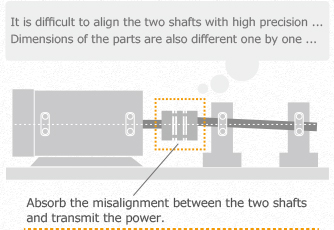

It takes a considerable amount of time to align the drive shaft to the driven shaft with high precision.

If the axes of two shafts are misaligned, an extra force is repeatedly applied to the surrounding parts as it rotates, which causes vibration and noise.

In addition, even though the same parts are used to manufacture units, there are errors such as machining accuracy, so it is very difficult to assemble every unit with accuracy, because the dimensions are different one by one.

Therefore, a coupling should be used to absorb such mounting errors.

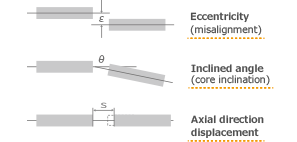

Coupling has the role of transmitting power dynamically and accurately even if there is a misalignment (eccentricity / declination angle, axial displacement, etc.) between the two shafts.

What is mounting error?

3.Absorb vibrations to protect surrounding products

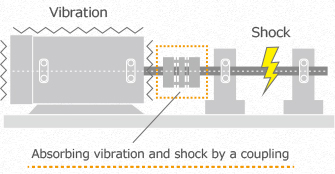

Vibration and shock may be transferred to surrounding parts when using the machine.

For example, if the vibration of a motor, etc. in the driving side is transmitted to the ball screw, etc., it deviates the machine from the prescribed position and it is impossible to make the good use of the machine’s performance.

Also, if a machine with no coupling receives an impact from the outside, the impact may be transmitted directly to the motor and may cause damage to the motor.

A coupling is the solution to this problem. It absorbs vibration in order to move the driven side with high accuracy, and/or shock to prevent expensive motors, etc. from damaging.

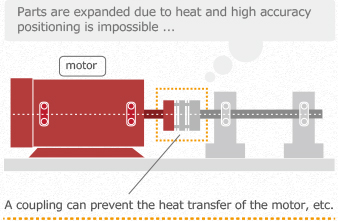

4.Do not transfer the heat of the motor, etc. to the driven side.

A motor generates a lot of heat when it is used.

When it is transmitted to the driven side, the ball screw, etc. expand by heat and the length will be changed.

As a result, the positioning accuracy is affected, and the expected machine precision will be not realized.

However, by using a coupling, it is possible to prevent the heat transfer of the motor, etc. so that the parts will not be deformed or shifted from its correct position.

As explained so far, the necessity to use couplings varies depending on the application and situation.

Couplings can provide multiple performances such as absorption of mounting errors (flexibility), high positioning accuracy (high rigidity), contribution to higher accuracy and longer service life by absorbing vibration and blocking of heat transfer.

There are many kinds of couplings.

It is necessary to understand what kind of features are available and what kind of application they will be suitable, and then select an appropriate coupling suitable for the intended use.

So, what kind of couplings are there? Please see the following:

- Summary1 What is a Coupling?

- ・A part that connects (connects) the two shafts of the machine together.

- ・A part that accurately conveys the power of the machine.

- ・A part that absorbs the mounting error in the axis of the machine.

- Summary2 Performance required for coupling

- ・Flexibility (absorbing mounting error)

- ・High rigidity

- ・High precision

- ・Vibration absorption

Types and features of couplings (shaft fittings)

In the following table, the type and features of the couplings (shaft fittings) are shown with using Miki pulley as an example.

Please use the table as reference for your daily selection work.

◯: Suitable △: Suitable for some applications

| Coupling Models |

Photo | Discription | Zero back lash |

High torsio nal rigid ity |

Damp ing |

Oil proof |

Indu ction motor |

Servo motor |

Step per motor |

En coder |

|---|---|---|---|---|---|---|---|---|---|---|

| Metal Disc type |

|

· The flexible metal disc elements allow for varying degrees of misalignment. ・Excellent fit for high speed rotation applicationt. | ○ | ○ | ○ | ○ | ○ | ○ | ||

| Rigid type |

|

· Cylindrical simple structure · Ultra-high rigidity with low inertia |

○ | ○ | ○ | ○ | ||||

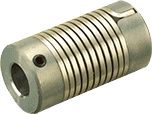

| Spring coupling |

|

· The coil spring element allows for varying degrees of misalignment · High flexibility and high transmittable torque |

△ | ○ | ○ | △ | △ | |||

| Pin and bush type |

|

· The sliding pin and bush allow large misalignment, and very low reaction force | △ | ○ | △ | △ | ||||

| Mugnet type |

|

· Permanent magnet force transmitted power without mechanical contacting · These features ideal for clean rooms and food processing application |

○ | ○ | ○ | |||||

| High vibration damping laminated s rubber type |

|

· High dampening characteristics absorbs resonances of servomotor or stepper motor | ○ | ○ | ○ | ○ | ||||

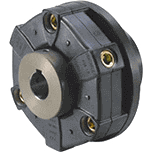

| Jaw type |

|

· Two hubs interpose rubber or elastomer element structure absorbs vibration

· Easy installation |

△ | ○ | △ | ○ | ○ | ○ | ||

| Bellows type |

|

· Structure of 2 hubs and plastic bellows · Compact and high flexibility |

○ | △ | ○ | △ | ||||

| Rubber/ elastomer element type |

|

· Compressed rubber structure, elastomer element structure · Suitable for engine applications for vibration absorbing |

○ | △ | ○ |

Miki Pulley's Coupling (Shaft Fitting) Variation

Miki Pulley has various types of couplings covering a wide range of drive sources, from general-purpose motors to servo motors that require super precision control to engines that generate large vibrations and shocks.

For example, Metal Leaf Spring (disk type) Couplings for servo motor applications and Laminated Rubber Couplings with High Damping Performance, realizing high damping and low reaction force.

In addition, Metal Slit Type Couplings with a spiral slit integral structure and Jaw Couplings for versatile use.

And Rubber/Resin Type Couplings for Prime Mover that absorb vibration and impact by elastic rubber.

Miki Pulley proposes optimum couplings according to each customer's application from many kinds of couplings with various features as introduced here.

Features of Miki Pulley couplings (shaft fitting)

Couplings of Miki Pulley, boasting the top market share, has tens of thousands of variations.

Since Miki Pulley also provides flexible customization and its mass production according to your specific needs, you can create most suitable couplings to your facility.

Thanks to many experienced engineers with excellent skills, Miki Pulley help cutomers to make a perfect selection of couplings that is most suitable for your facility. Please do not hesitate to contact us.

Miki Pulley couplings (shaft fitting)

Miki Pulley is the high technology company, unique to dedicated company on transmission equipments, and can provide most suitable couplings out of many standard types or customized couplings to solve various problems such as shaft deflection, shaft thermal expansion, oscillation/resonance phenomenon, and bearings wear.

>List of Miki Pulley couplings![]()

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어