![]()

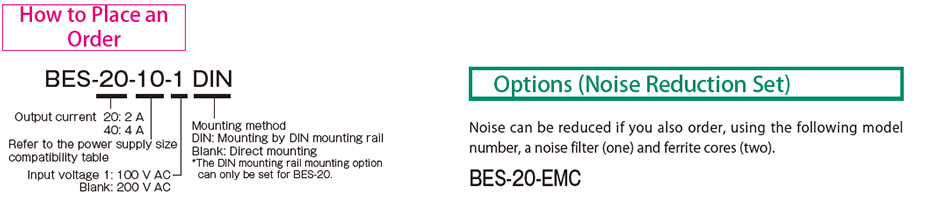

BES Models (For ordinary high-speed control) Specifications

BES Models

[Specifications]

| Model | BES-20-□-1 | BES-40-□-1 | BES-20-□ | BES-40-□ |

|---|---|---|---|---|

| Input voltage | AC100V ± 10% 50/60Hz | AC100V ± 10% 50/60Hz | AC200V ± 10% 50/60Hz | AC200V ± 10% 50/60Hz |

| Output current | 2.0 A | 4.0 A | 2.0 A | 4.0 A |

| Voltage control method | PWM control | |||

| Constant excitation voltage | Adjusted for each model and size at the time of shipment | |||

| Overexcitation voltage | DC 90 V Full-wave (with AC 100 V input) | DC 180 V Full-wave (with AC 200 V input) | ||

| Overexcitation time | Adjusted for each model and size at the time of shipment | |||

| Protective functions | Input side Quick-acting fuse (5A) | |||

| Insulating resistance | DC 500 V With Megger 100 M Ω (between terminal and main body) | |||

| Dielectric strength voltage | AC 1000 V 50 Hz 1 min. (between terminal and main body) | |||

| Usage environment | -10℃ to +50℃/10% to 90% RH (with no condensation) | |||

| Mass | 0.3 kg | 0.7 kg | 0.3 kg | 0.7 kg |

*The voltage that is output is not insulated from the power supply, so shocks can result if touched.

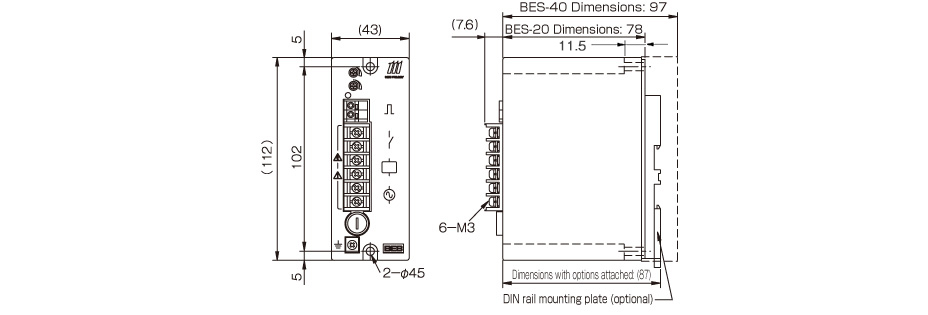

[Dimensions]

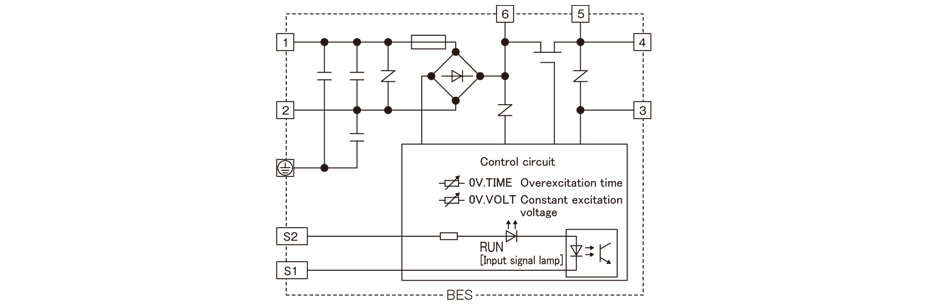

[Structure]

[Terminals and Functions]

| Terminal symbol | Terminal name | Function description |

|---|---|---|

| 1-2 | Power supply input terminal | Connector for a commercial power supply |

| 3-4 | Output terminal | Connector for an electromagnetic clutch or brake |

| 5-6 | Control terminal 1 | Output is controlled by opening and closing between terminals using a relay or the like. |

| Ground terminal | External ground terminal (third class ground or more) | |

| S1-S2 | Control terminal 2 | Output is controlled by turning the DC 24 V on and off (30 mA, smoothing power supply) |

[Characteristics]

Operating Response

All circuits have been made contactless, and response from signal input to output to the electromagnetic-actuated clutch or brake is fast and stable.

Energy Saving

Standby power is “zero.” Absolutely no electricity is wastefully consumed.

By combining this power supply with a MIKI PULLEY spring-actuated brake, the electricity consumption and heat generation of the springactuated brake is reduced by more than 70%, saving energy.

By combining this power supply with a MIKI PULLEY spring-actuated brake, the electricity consumption and heat generation of the springactuated brake is reduced by more than 70%, saving energy.

Noise During Operation

BES models use a quiet design, but electromagnetic clutches and brakes may produce excitation noise when operating under some mounting conditions. This noise is not abnormal and is not cause for concern.

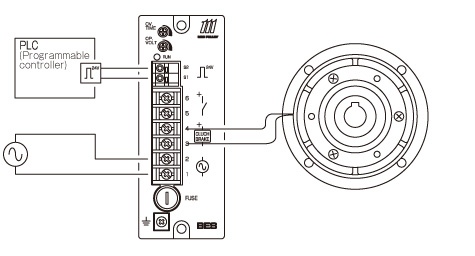

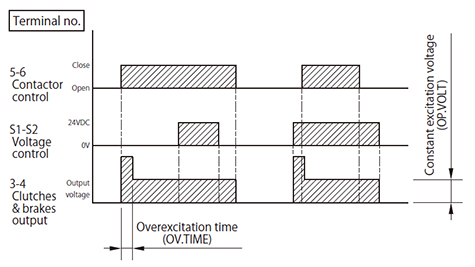

Two Types of Control Systems

You can operate under either PLC control (which uses voltage control via programmable controllers or the like) or contactor control (which controls using relays and the like).

In the case of contactor control, however, a power controller for controlling the power supply line must be used.

In the case of contactor control, however, a power controller for controlling the power supply line must be used.

Supply Voltage Fluctuations and Output Voltage

BES model power supplies are designed to operate reliably even when supply voltage fluctuates. Characteristically, however, their output voltage will rise or fall along with rises and falls of supply voltage. To fulfill electromagnetic clutch/brake performance, supply voltage fluctuations should be kept within a range of ± 10%.

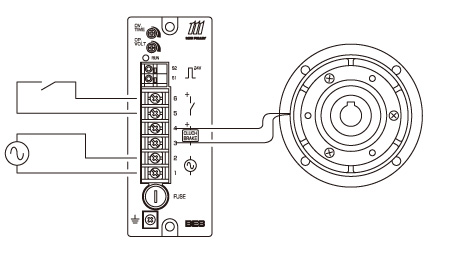

[Wiring Methods and Timing Charts]

Wiring 1 (PLC Control)

Wiring 2 (Contactor Control)

Time Chart

[Table of Power Supply/Size Correspondence]

| MIKI PULLEY electromagnetic-actuated clutch/brake size | 02 | 025 | 03 | 04 | 05 | 06 | 08 | 10 | 12 | 16 | 20 | 25 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal power supply output current | 20 | 40 | |||||||||||

| Power supply size | Excitation voltage For 24 V ( Input voltage 100/200 V・Constant excitation voltage 24 V ) | 05 | 10 | 16 | 20 | 25 | |||||||

| MIKI PULLEY electromagnetic tooth clutch sizes | 12 | 13 | 15 | 21 | 23 | 25 | 31 | 32 | |

|---|---|---|---|---|---|---|---|---|---|

| Nominal power supply output current | 20 | 40 | |||||||

| Power supply size | Excitation voltage For 24 V ( Input voltage 100/200 V・Constant excitation voltage 20 V ) | 51 | 52 | 53 | |||||

| MIKI PULLEY spring-actuated brake size | 01 | 02 | 03 | 04 | 05 | 06 | 08 | 10 | 12 | 14 | 16 | 18 | 20 | 25 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Nominal power supply output current | 20 | ||||||||||||||

| Power supply size | Excitation voltage 45 V ( Input voltage 100 V・Constant excitation voltage 20 V ) Excitation voltage 90 V ( Input voltage 200 V・Constant excitation voltage 30 V ) Excitation voltage For 24 V ( Input voltage 100/200 V・Constant excitation voltage 10 V ) |

61 61 71 |

62 62 72 |

63 63 73 |

|||||||||||

Related Product

Basic Specifications

- Clutch torque 17.5 N・m to 2200 N・m

- Operating temperature 0℃ to 40℃

- Backlash Zero

Basic Specifications

- Clutch/brake torque 5 N・m to 40 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

Basic Specifications

- Brake torque 0.4 N・m to 2.4 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

Basic Specifications

- Input voltage AC 100 V, AC 200 V, AC 400 V

- Output voltage DC 45 V, DC 90 V, DC 180 V

- Operating temperature -10℃ to 60℃

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어