What is magnetic coupling and magnet gear?

Magnetic coupling & gear is non-contact power transmission device by magnetic atraction & repulsion force

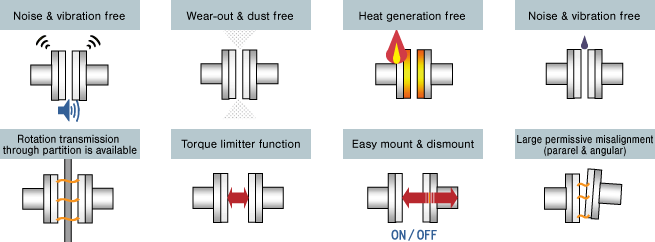

You may have a lot of advantage of non-contact powertransmission.

INDEX

Structure and role of magnetic coupling & gear

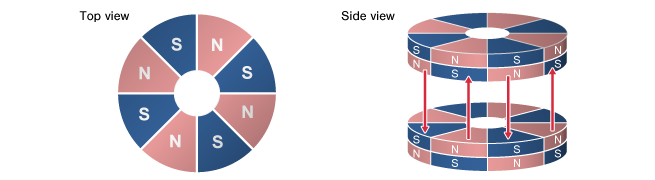

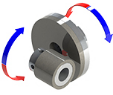

Structure

Multi-poles structure by alternate magnetized N poles & S poles.

Utilize attraction force between different poles,and repulsion force between same poles to transmit rotation power.

Role

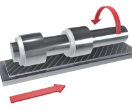

Role of magnetic coupling & gear is to transmit rotation power or transfer rotational motion to linear motion without mechanical contact such as by traditional coupling, gear and ball screw.

| Type of products | Shaft combination | Equivalent products | Role |

|---|---|---|---|

|

Butting | Coupling | [Non-contact] Rotational transmission |

|

Pararell | Spur gear, Helical gear |

|

|

Right angles | Bevel gear | |

|

Right angles | Miter gear | |

|

Linear motion mechanism(parallel) | Ball screw, linear motor |

[Non-contact] Transfer Rotation to linear motion |

|

Linear motion mechanism(right angle) | Rack and Pinion |

Type & Feature of Magnetic couplings and gears

| Photo | Series | Equivalent items | Features |

|---|---|---|---|

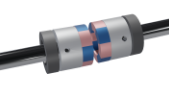

|

CP | Couplings |

・Easy centering, mount & dismount ・Torque limitter function ( Out of synchronism at over load ) ・Suitable for rotation transmission through partition |

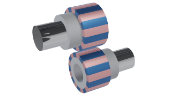

|

SCP | Coupling |

・Stainless coverer coupling ・Water proof ・Suitable for medical & food processing machine ・Easy centering, mount & dismount ・Torque limitter function ( Out of synchronism at over load ) ・Suitable for rotation transmission through partition |

|

PCP | Coupling |

・Plastic covered coupling ・For use in acid environments ・Easy centering, mount & dismount ・Torque limitter function ( Out of synchronism at over load ) ・Suitable for rotation transmission through partition |

|

CO | Spur gear, Helical gear |

・Easy mount & dismount ・Torque limitter function ( Out of synchronism at over load ) ・Low noise, maintanance free |

|

MP/ML | Bevel gear, Miter gear |

・Easy torque adjusting ・Easy mount adjusting ・Low noise, maintanance free |

|

LS | Ball screw |

・Wireless, non-contact linear motion mechanism ・No limited length available |

|

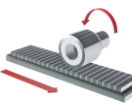

RP | Rack and Pinion |

・Low noise, maintanance free ・No metal jumming |

Example solutions by magnetic coupling & gear

Magnetic products suit for those who have troubles as below.

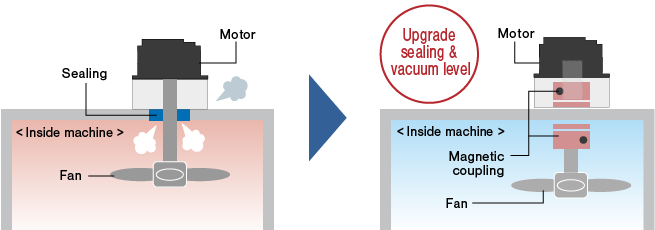

1. We want to transmit the rotation through

the partition wall. (No sealing is required.)

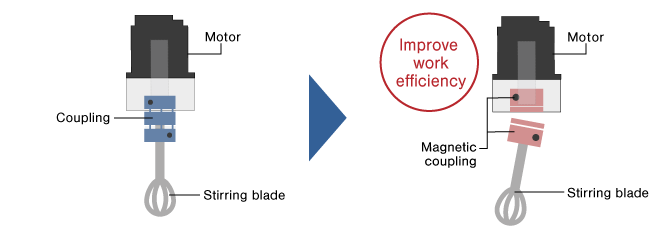

[Application] Liquid mixer ( Sealed container )

Recommended for eliminating sealing and improving sealing!

[Movie] Transmission through partition wall (Water container)

2. We are in trouble of frequent parts

mount-dismount & maintanance.

[Application] Food mixing machine

Magnetic coupling promise you easy replacement & maintanance of stirring blade!

Recommended for food machine required frequent cleaning, as well as frequent attachment replacing required machine.

[Movie] Transmission through partition wall (Mixing machine)

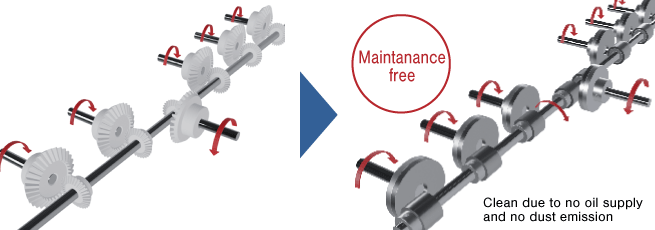

3. We want to reduce noise & vibration.

[Application] Transportation equipment, conveyor

You may eliminate micro-step vibration or driving noise caused by mechanical gears.Recommended for presision devices handling due to less influence of vibration, no wear-out of gear.

Frequent queries for Magnetic couplings & gears

Q1.Would magnetic force be devreased?

A1. Decreased maximum 0.1% per year.

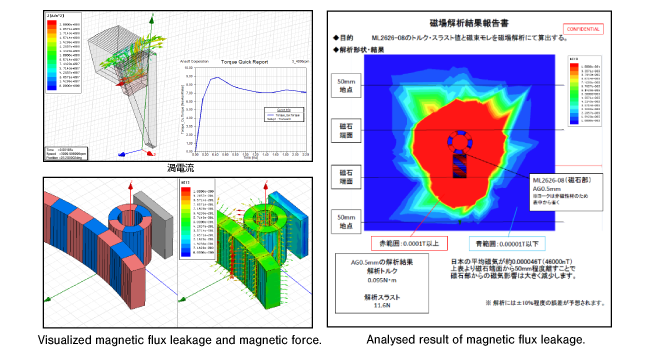

Q2. Is there any influence to sorrounding devices

by magnetic flux leakage?

A2. Almost no influece if apart 50mm from magnet .

Please feel free to contact us for magnetic field analysis service.

Q3.What is maximum operating environment temperature?

A3.Maximum torque described in website is under room temparature.

Torque decrease step by step in accordance with temparature increase.

Please contact us in case of usage under high temparature.

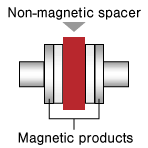

Q4. Is there any points of attention for assembling?

A4. Here is the points of attention for assembling.

Please fix magnetic products onto the shaft after placing the spacer which is non-magnetic, high stiffness, and high sliding nature.

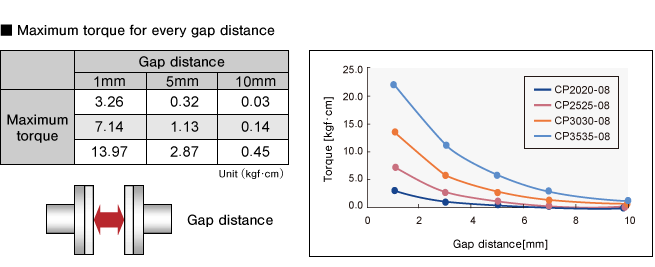

Q5.Does the torque change according to the gap between

both hubs at assembling?

A5.Transmittable torque will decreased when the air-gap is wider, while increased when it is narrower.

Please confirm the maximum torque for every gap distance by the chart.

*You can use the products as torque limitter since maximum torque (slip torque) is adjustable.

※Above data is example of CP series.

For the other model,please refer to the product page in our website.

INDEX

Please leave it to us anything about magnetic couplings & gears.

·What is the benefit of magnetic couplings or gears for our facilities?

·I want to reconsider the magnetic couplings or gears in our facilities.

·Need advice how to select the suitable model.

·If you have such queries or requests as above,

please feel free to contact us from the inquiry form below.

·Our engineer will explain the products benefit and suggest suitable one for your facilities.

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어