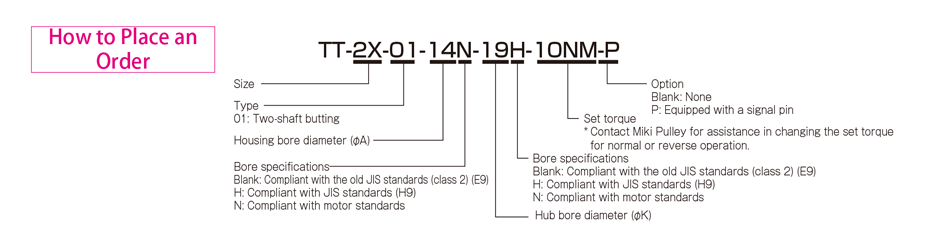

Torque Limiters TT(01) Types Specifications

TT (01) Types

[Specifications]

| Type | Size | Set torque value [N・m] | Misalignment | Max. rotation speed [min-1] | Moment of inertia [kg・m2] | Mass [kg] |

|---|

| Spring color | Parallel | Angular |

|---|

| Colorless | Blue | Red | Yellow | White | Gray | Green | Brown* | Colorless* | [mm] | [°] |

|---|

| TT-1X-01 | 1X | 0.2 | 0.5 | 1.0 | 1.5 | 2.0 | 2.5 | 3.0 | 3.5 | 4.0 | 0.2 | 0.5 | 1800 | 0.06×10-3 | 0.3 |

|---|

| TT-2-01 | 2 | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 10 | 0.2 | 0.5 | 1800 | 0.26×10-3 | 0.7 |

|---|

| TT-2X-01 | 2X | 2 | 3 | 5 | 8 | 10 | 12 | 15 | 18 | 20 | 0.2 | 0.5 | 1800 | 0.52×10-3 | 1.0 |

|---|

| TT-3-01 | 3 | 5 | 8 | 10 | 15 | 20 | 25 | 30 | 35 | 40 | 0.2 | 0.5 | 1800 | 1.23×10-3 | 1.5 |

|---|

| TT-3X-01 | 3X | 10 | 16 | 20 | 30 | 40 | 50 | 60 | 70 | 80 | 0.2 | 0.5 | 1800 | 1.94×10-3 | 2.7 |

|---|

| TT-4X-01 | 4X | 20 | 30 | 50 | 80 | 100 | 120 | 150 | 180 | 200 | 0.2 | 0.5 | 500 | 14.8×10-3 | 6.3 |

|---|

*The above set torque values listed are measured at a speed of 1500 min-1.

* Set torque values vary by ± 20%.

*Use components with larger dimensions for applications with the torque marked by [*] requiring enhanced reliability.

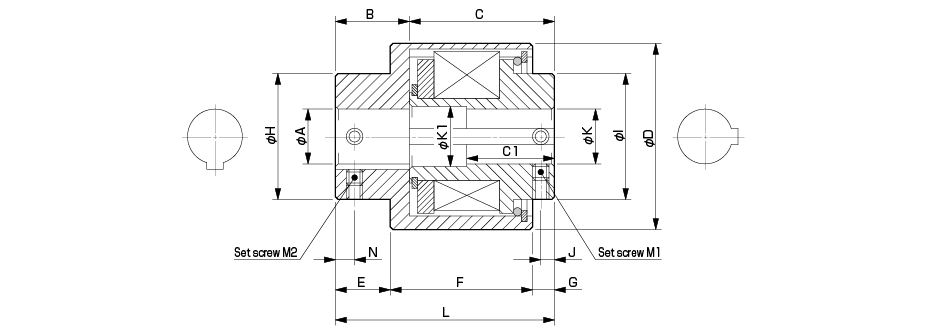

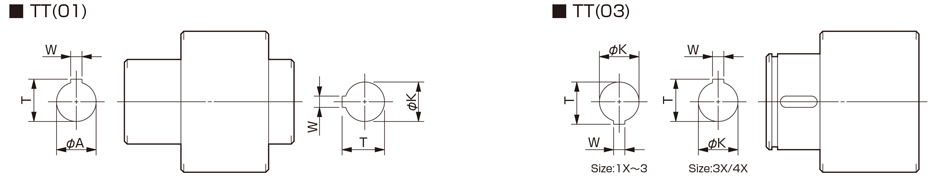

[Dimensions]

Unit [mm]

| Size | K1 | B | C | C1 | D | E | F | G | H | I | J | L | N | M1 | M2 |

|---|

| 1X | 12.5 | 20 | 30 | 23 | 42 | 15 | 30 | 5 | 25 | 22 | 3 | 50 | 6 | 2-M4 | 2-M4 |

|---|

| 2 | 16.5 | 24.5 | 41.5 | 32.5 | 55 | 20 | 35 | 11 | 35 | 32 | 5 | 66 | 7 | 2-M5 | 2-M5 |

|---|

| 2X | 20.5 | 31 | 45 | 34 | 65 | 25 | 40 | 11 | 40 | 38 | 5 | 76 | 8 | 2-M5 | 2-M5 |

|---|

| 3 | 25.5 | 37.5 | 53.5 | 40 | 75 | 30 | 50 | 11 | 45 | 45 | 5 | 91 | 10 | 2-M6 | 2-M6 |

|---|

| 3X | 25.5 | 36 | 85 | 41 | 75 | 30 | 80 | 11 | 45 | 45 | 6 | 121 | 10 | 2-M6 | 2-M6 |

|---|

| 4X | 28.5 | 46 | 95 | 60 | 120 | 35 | 90 | 16 | 80 | 80 | 8 | 141 | 12 | 2-M10 | 2-M10 |

|---|

*For size 4X with φ K at 30 mm or more, shape is straight and there are no K1/C1 dimensions.

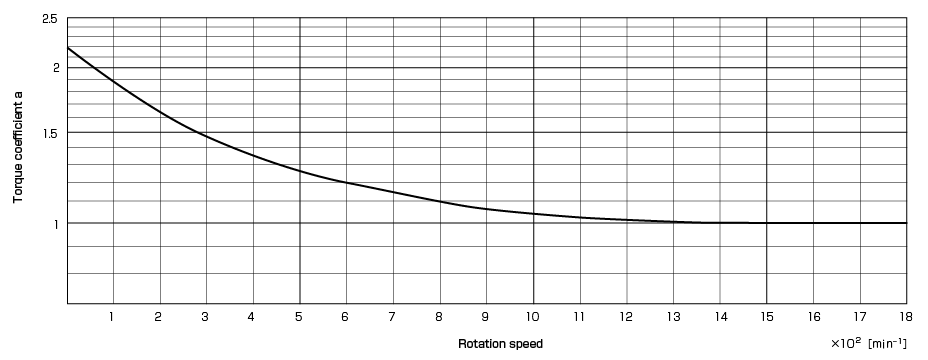

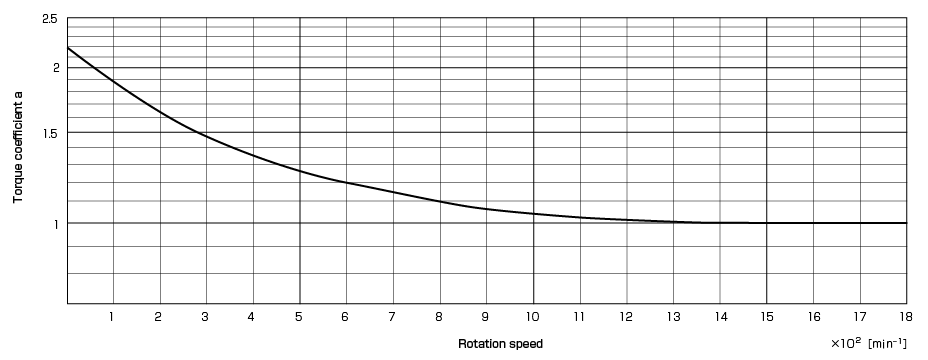

[Torque coefficient]

[Standard Bore Diameterφ A]

| Model | Bore DrillingH

Standards | Nominal bore

Standards | Standard bore diameter A [mm] |

|---|

| 8 | 10 | 11 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 |

|---|

| TT-1X-01 | Old JIS standards (E9) | Blank | ● | ● | ● | ● | ● | | | | | | | | | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | ● | ● | ● | ● | | | | | | | | | | | | | | | | | | |

| Motor standards | N | | | | | ● | | | | | | | | | | | | | | | | | | |

| TT-2-01 | Old JIS standards (E9) | Blank | | | ● | ● | ● | ● | ● | ● | ● | ● | | | | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | | ● | ● | ● | ● | ● | ● | ● | ● | | | | | | | | | | | | | |

| Motor standards | N | | | | | ● | | | | ● | | | | | | | | | | | | | | |

| TT-2X-01 | Old JIS standards (E9) | Blank | | | | | ● | ● | ● | ● | ● | ● | ● | ● | | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | | | | ● | ● | ● | ● | ● | ● | ● | ● | | | | | | | | | | | |

| Motor standards | N | | | | | ● | | | | ● | | | ● | | | | | | | | | | | |

| TT-3-01 | Old JIS standards (E9) | Blank | | | | | | | | ● | ● | ● | ● | ● | ● | ● | ● | | | | | | | | |

|---|

| JIS standards (H9) | H | | | | | | | | ● | ● | ● | ● | ● | ● | ● | ● | | | | | | | | |

| Motor standards | N | | | | | | | | | ● | | | ● | | ● | | | | | | | | | |

| TT-3X-01 | Old JIS standards (E9) | Blank | | | | | | | | | ● | ● | ● | ● | ● | ● | ● | | | | | | | | |

|---|

| JIS standards (H9) | H | | | | | | | | | ● | ● | ● | ● | ● | ● | ● | | | | | | | | |

| Motor standards | N | | | | | | | | | ● | | | ● | | ● | | | | | | | | | |

| TT-4X-01 | Old JIS standards (E9) | Blank | | | | | | | | | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

|---|

| JIS standards (H9) | H | | | | | | | | | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| Motor standards | N | | | | | | | | | ● | | | ● | | ● | | | | ● | | ● | | ● | |

* There is no keyway for bore diameter ø8 mm.

[Standard Bore Diameterφ K]

| Model | Bore Drilling

Standards | Nominal bore

diameter | Standard bore diameter K [mm] |

|---|

| 8 | 10 | 11 | 12 | 14 | 15 | 16 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 |

|---|

| TT-1X-01 | Old JIS standards (E9) | Blank | ● | ● | ● | ● | | | | | | | | | | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | ● | ● | ● | | | | | | | | | | | | | | | | | | | |

| Motor standards | N | | | | | | | | | | | | | | | | | | | | | | | |

| TT-2-01 | Old JIS standards (E9) | Blank | | | ● | ● | ● | ● | ● | | | | | | | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | | ● | ● | ● | ● | ● | | | | | | | | | | | | | | | | |

| Motor standards | N | | | | | ● | | | | | | | | | | | | | | | | | | |

| TT-2X-01 | Old JIS standards (E9) | Blank | | | | | ● | ● | ● | ● | ● | ● | | | | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | | | | ● | ● | ● | ● | ● | | | | | | | | | | | | | | |

| Motor standards | N | | | | | ● | | | | ● | | | | | | | | | | | | | | |

| TT-3-01 | Old JIS standards (E9) | Blank | | | | | | | | ● | ● | ● | ● | ● | ● | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | | | | | | | ● | ● | ● | ● | ● | ● | | | | | | | | | | |

| Motor standards | N | | | | | | | | | ● | | | ● | | | | | | | | | | | |

| TT-3X-01 | Old JIS standards (E9) | Blank | | | | | | | | ● | ● | ● | ● | ● | ● | | | | | | | | | | |

|---|

| JIS standards (H9) | H | | | | | | | | ● | ● | ● | ● | ● | ● | | | | | | | | | | |

| Motor standards | N | | | | | | | | | ● | | | ● | | | | | | | | | | | |

| TT-4X-01 | Old JIS standards (E9) | Blank | | | | | | | | | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | | |

|---|

| JIS standards (H9) | H | | | | | | | | | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | | |

| Motor standards | N | | | | | | | | | ● | | ● | | ● | | | | ● | | ● | | | | |

* There is no keyway for bore diameter ø8 mm.

Options of Torque Limiters TT(01) Types

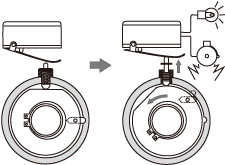

Optional Signal Pin

Unattended or remotely controlled machines and equipment require equipment that detects an overload and automatically switches off the power or sounds a warning alarm.

An overload can be detected by connecting the signal pin to the torque tender.

When an overload is detected, the input side and the output side are disconnected and the cam mechanism of the torque tender hub pushes the signal pin out in the radial direction. This can be used to switch off the power or sound a warning alarm.

Be sure to use the housing as the input side.

The standard product cannot be modified to connect the signal pin. If you need to

connect the signal pin, add "-P" to the end of the model when you order the product.

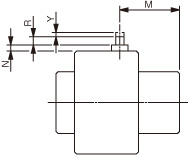

Unit (mm)

| Size |

M |

Y |

R |

N |

| 1X |

24 |

1.5 |

6.5 |

5.5 |

| 2 |

29 |

2.5 |

5 |

4.5 |

| 2X |

36 |

2.5 |

5 |

4.5 |

| 3 |

43 |

2.5 |

5 |

4.5 |

| 3X |

42 |

2.5 |

5 |

4.5 |

| 4X |

55 |

2.5 |

5 |

2 |

Standard Hole-Drilling Standards

*Set screws are included with the product.

*For standard dimensions for bore drilling other than those given here, contact Miki Pulley.

(A bore may not be able to be drilled for some hub sizes.)

Unit [mm]

| Models compliant with the old JIS standard (class 2) JIS B 1301 1959 |

Models compliant with the new JIS standard (H9) JIS B 1301 1996 |

Models compliant with the motor standard JIS C 4210 2001 |

Nominal bore

diameter |

Bore

diameter

[oA/oK] |

Keyway

width

[W] |

Keyway

height

[T] |

Nominal bore

diameter |

Bore

diameter

[oA/oK] |

Keyway

width

[W] |

Keyway

height

[T] |

Nominal bore

diameter |

Bore

diameter

[oA/oK] |

Keyway

width

[W] |

Keyway

height

[T] |

|

Tolerance

H7 |

Tolerance

E9 |

- |

|

Tolerance

H7 |

Tolerance

H9 |

- |

|

Tolerance

G7 |

|

- |

| 8 |

8+0.0150 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 10 |

10+0.0150 |

4+0.050+0.020 |

11.5+0.50 |

10H |

10+0.0150 |

4+0.0300 |

11.8+0.50 |

- |

- |

- |

- |

| 11 |

11+0.0180 |

4+0.050+0.020 |

12.5+0.50 |

11H |

11+0.0180 |

4+0.0300 |

12.8+0.50 |

- |

- |

- |

- |

| 12 |

12+0.0180 |

4+0.050+0.020 |

13.5+0.50 |

12H |

12+0.0180 |

4+0.0300 |

13.8+0.50 |

- |

- |

- |

- |

| 14 |

14+0.0180 |

5+0.050+0.020 |

16.0+0.50 |

14H |

14+0.0180 |

5+0.0300 |

16.3+0.50 |

14N |

14+0.024+0.006 |

5+0.0300 |

16.0+0.50 |

| 15 |

15+0.0180 |

5+0.050+0.020 |

17.0+0.50 |

15H |

15+0.0180 |

5+0.0300 |

17.3+0.50 |

- |

- |

- |

- |

| 16 |

16+0.0180 |

5+0.050+0.020 |

18.0+0.50 |

16H |

16+0.0180 |

5+0.0300 |

18.3+0.50 |

- |

- |

- |

- |

| 18 |

18+0.0180 |

5+0.050+0.020 |

20.0+0.50 |

18H |

18+0.0180 |

6+0.0300 |

20.8+0.50 |

- |

- |

- |

- |

| 19 |

19+0.0210 |

5+0.050+0.020 |

21.0+0.50 |

19H |

19+0.0210 |

6+0.0300 |

21.8+0.50 |

19N |

19+0.028+0.007 |

6+0.0300 |

21.5+0.50 |

| 20 |

20+0.0210 |

5+0.050+0.020 |

22.0+0.50 |

20H |

20+0.0210 |

6+0.0300 |

22.8+0.50 |

- |

- |

- |

- |

| 22 |

22+0.0210 |

7+0.061+0.025 |

25.0+0.50 |

22H |

22+0.0210 |

6+0.0300 |

24.8+0.50 |

- |

- |

- |

- |

| 24 |

24+0.0210 |

7+0.061+0.025 |

27.0+0.50 |

24H |

24+0.0210 |

8+0.0360 |

27.3+0.50 |

24N |

24+0.028+0.007 |

8+0.0360 |

27.0+0.50 |

| 25 |

25+0.0210 |

7+0.061+0.025 |

28.0+0.50 |

25H |

25+0.0210 |

8+0.0360 |

28.3+0.50 |

- |

- |

- |

- |

| 28 |

28+0.0210 |

7+0.061+0.025 |

31.0+0.50 |

28H |

28+0.0210 |

8+0.0360 |

31.3+0.50 |

28N |

28+0.028+0.007 |

8+0.0360 |

31.0+0.50 |

| 30 |

30+0.0210 |

7+0.061+0.025 |

33.0+0.50 |

30H |

30+0.0210 |

8+0.0360 |

33.3+0.50 |

- |

- |

- |

- |

| 32 |

32+0.0250 |

10+0.061+0.025 |

35.5+0.50 |

32H |

32+0.0250 |

10+0.0360 |

35.3+0.50 |

- |

- |

- |

- |

| 35 |

35+0.0250 |

10+0.061+0.025 |

38.5+0.50 |

35H |

35+0.0250 |

10+0.0360 |

38.3+0.50 |

- |

- |

- |

- |

| 38 |

38+0.0250 |

10+0.061+0.025 |

41.5+0.50 |

38H |

38+0.0250 |

10+0.0360 |

41.3+0.50 |

38N |

38+0.034+0.009 |

10+0.0360 |

41.0+0.50 |

| 40 |

40+0.0250 |

10+0.061+0.025 |

43.5+0.50 |

40H |

40+0.0250 |

12+0.0430 |

43.3+0.50 |

- |

- |

- |

- |

| 42 |

42+0.0250 |

10+0.061+0.025 |

45.5+0.50 |

42H |

42+0.0250 |

12+0.0430 |

45.3+0.50 |

42N |

42+0.034+0.009 |

12+0.0430 |

45.0+0.50 |

| 45 |

45+0.0250 |

12+0.075+0.032 |

48.5+0.50 |

45H |

45+0.0250 |

14+0.0430 |

48.8+0.50 |

- |

- |

- |

- |

| 48 |

48+0.0250 |

12+0.075+0.032 |

51.5+0.50 |

48H |

48+0.0250 |

14+0.0430 |

51.8+0.50 |

48N |

48+0.034+0.009 |

14+0.0430 |

51.5+0.50 |

| 50 |

50+0.0250 |

12+0.075+0.032 |

53.5+0.50 |

50H |

50+0.0250 |

14+0.0430 |

53.8+0.50 |

- |

- |

- |

- |

![]()

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어