Load Torque Calculation Formula

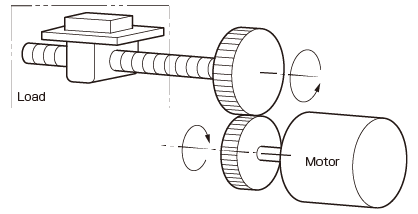

Motor Shaft Conversion Torque: TO

Z1 : Teeth number of the motor-side gear

Z

2 : Teeth number of the load-side gear

R : Speed reduction ratio Z2/Z1

η : Transmission efficiency % /100

T : Load-side torque[N・m]

| To= | 1 | ・T・ | 1 | [N・m] |

| R | η |

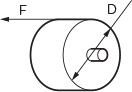

Torque when Adding the External Force of the Rotating Object: T

D : Diameter of the drum [m]

F : External force[N]

| T= | 1 | D・F [N・m] |

| 2 |

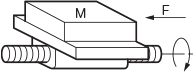

Torque by Friction Force of the Feed Screw and External Force: T

P : Feed screw lead[m]

M : Mass of the load [kg]

g : Gravitational acceleration[m/s2]

μ : Friction coefficient of the feed screw

F : External force[N]

| T= | 1 | P(F+μMg) [N・m] |

| 2π |

(Normally, μ : approximately 0.05 to 0.2)

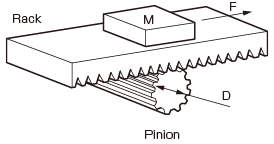

Torque by Friction Force of Rack and Pinion and External Force: T

D : Diameter of the pinion [m]

M : Mass of the load [kg]

g : Gravitational acceleration[m/s2]

μ : Friction coefficient of the rack and pinion

F : External force[N]

| T= | 1 | D(F+μMg)[N・m] |

| 2 |

(Normally, μ : approximately 0.08 to 0.1)

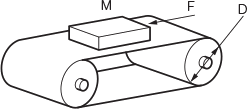

Torque by Friction Force of Conveyor and External Force: T

D : Diameter of the roller [m]

M : Mass of the load [kg]

g : Gravitational acceleration[m/s2]

μ : Friction coefficient of the conveyor

F : External force [N]

| T= | 1 | D(F+μMg)[N・m] |

| 2 |

(Normally, μ : approximately 0.05 to 0.1)

* The friction coefficient value μ varies depending on the machine processing accuracy, lubrication condition, and other factors.

Pay enough attention when calculating the load torque.

* The transmission efficiency η between the motor and load varies depending on the connection method. The following shows typical values.

Spur gear: 0.85 Chain: 0.9 V-belt: 0.9

Other Technical Documents

- General Tolerances(Excerpt from JIS B 0405 1991/JIS B 0419 1991)

- MIKI PULLEY Coupling Standard Hole Drilling Standards

- MIKI PULLEY Clutch and Brake Standard Hole Drilling Standards

- Frequently Used Fits

- Fitting Tolerances(Excerpt from JIS B 0401)

- International System of Units (SI)

- Hexagon Socket Head Cap Bolts (Excerpt from JIS B 1176 2014)

- Hexagon Bolts (Excerpt from JIS B 1180 2014)

- Hexagon Socket Set Screws (Excerpt from JIS B 1177 2007)

- Hex Keys (Excerpt from JIS B 4648 2008)

- Parallel Key and Keyway Sizes and Tolerances

- Retaining Ring (Excerpt from JIS B 2804 2010)

- Bearing Mounting Dimensions

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어