![]()

121(20G) Types (Clutches and brakes) Specifications

121 (20G) Types

[Specifications]

| Model | Size | Dynamic friction torque Td [N・m] | Static friction torque Ts [N・m] | Coil (at 20℃) | Heat resistance class | Max. rotation speed [min-1] | Rotating part moment of inertia J [kg・m2] | Total work performed until readjustment of the air gap ET [J] | Armature pull-in time ta [s] | Torque build-up time tp [s] | Torque decaying time td [s] | Mass [kg] | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage [V] | Wattage [W] | Current [A] | Resistance [Ω] | ||||||||||||

| 121-06-20G | 06 | 5 | 5.5 | 24 DC | 11 | 0.46 | 52 | B | 3000 | 1.43×10-4 | 36×106 | C: 0.020/B: 0.015 | C: 0.041/B: 0.033 | C: 0.020/B: 0.015 | 1.5 |

| 121-08-20G | 08 | 10 | 11 | 24 DC | 15 | 0.63 | 38 | B | 3000 | 4.23×10-4 | 60×106 | C: 0.023/B: 0.016 | C: 0.051/B: 0.042 | C: 0.030/B: 0.025 | 2.7 |

| 121-10-20G | 10 | 20 | 22 | 24 DC | 20 | 0.83 | 29 | B | 3000 | 1.42×10-3 | 130×106 | C: 0.025/B: 0.018 | C: 0.063/B: 0.056 | C: 0.050/B: 0.030 | 5.5 |

| 121-12-20G | 12 | 40 | 45 | 24 DC | 25 | 1.04 | 23 | B | 3000 | 4.18×10-3 | 250×106 | C: 0.040/B: 0.027 | C: 0.115/B: 0.090 | C: 0.065/B: 0.050 | 9.6 |

| 121-16-20G | 16 | 80 | 90 | 24 DC | 35 | 1.46 | 16 | B | 3000 | 1.34×10-2 | 470×106 | C: 0.050/B: 0.035 | C: 0.160/B: 0.127 | C: 0.085/B: 0.055 | 18.5 |

| 121-20-20G | 20 | 160 | 175 | 24 DC | 45 | 1.88 | 13 | B | 2500 | 4.13×10-2 | 10×108 | C: 0.090/B: 0.065 | C: 0.250/B: 0.200 | C: 0.130/B: 0.070 | 35 |

| 121-25-20G | 25 | 320 | 350 | 24 DC | 60 | 2.50 | 9.6 | B | 2000 | 1.02×10-1 | 20×108 | C: 0.115/B: 0.085 | C: 0.335/B: 0.275 | C: 0.210/B: 0.125 | 64 |

*The dynamic friction torque, Td, is measured at a relative speed of 100 min-1. Depending on the initial torque characteristics, break-in to condition the engaging surfaces may also be required.

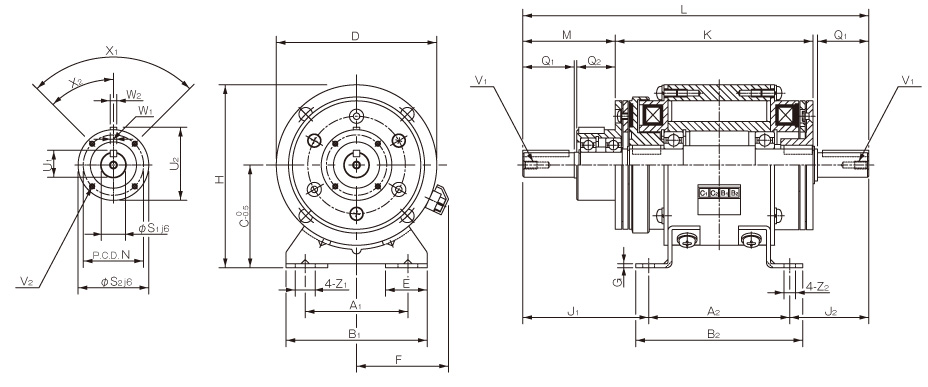

[Dimensions]

Unit [mm]

| Size | Dimensions of part | Dimensions of shaft | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | A2 | B1 | B2 | C | D | E | F | G | H | J1 | J2 | K | L | M | N | Z1 | Z2 | Q1 | Q2 | S1 | S2 | U1 | U2 | V1 | V2 | X1 | X2 | W1, 2 | |

| 6 | 52.5 | 75 | 80 | 90 | 55 | 80 | 27.5 | 53 | 2.6 | 95 | 65.5 | 40.5 | 105.5 | 181 | 47 | 33 | 13.5 | 6.5 | 25 | 20 | 11 | 38 | 12.5 | 39.5 | M4×0.7, length: 8 | 3-M4×0.7, length: 4 | 3-120° | 60° | 4 |

| 8 | 65 | 90 | 90 | 105 | 65 | 100 | 27.5 | 61 | 2.6 | 115 | 78.5 | 48.5 | 126.5 | 217 | 57 | 37 | 13.5 | 6.5 | 30 | 25 | 14 | 45 | 16 | 47 | M4×0.7, length: 8 | 3-M4×0.7, length: 6 | 3-120° | 60° | 5 |

| 10 | 80 | 110 | 110 | 130 | 80 | 125 | 32.5 | 72 | 3.2 | 142.5 | 98 | 62 | 154 | 270 | 72 | 47 | 15.5 | 9 | 40 | 30 | 19 | 55 | 21 | 57 | M6×1, length: 11 | 4-M4×0.7, length: 8 | 4-90° | 45° | 5 |

| 12 | 105 | 135 | 140 | 160 | 90 | 150 | 35 | 81 | 3.2 | 165 | 121 | 73.5 | 184 | 330 | 92 | 52 | 20 | 11.5 | 50 | 40 | 24 | 64 | 27 | 67 | M6×1, length: 11 | 4-M4×0.7, length: 8 | 4-90° | 45° | 7 |

| 16 | 135 | 160 | 175 | 185 | 112 | 190 | 43 | 97 | 4.5 | 207 | 149 | 90 | 221 | 399 | 113 | 62 | 24.5 | 11.5 | 60 | 50 | 28 | 75 | 31 | 78 | M6×1, length: 11 | 6-M5×0.8, length: 8 | 6-60° | 30° | 7 |

| 20 | 155 | 200 | 200 | 230 | 132 | 230 | 45 | 109 | 6 | 247 | 187 | 117 | 276 | 504 | 142 | 74.5 | 28 | 14 | 80 | 60 | 38 | 90 | 41.5 | 93.5 | M10×1.5, length: 17 | 4-M6×1, length: 12 | 4-90° | 45° | 10 |

| 25 | 195 | 240 | 240 | 270 | 160 | 290 | 47.5 | 124 | 20 | 305 | 238 | 154 | 334 | 632 | 183 | 101.5 | 28 | 14 | 110 | 70 | 42 | 115 | 45.5 | 118.5 | M10×1.5, length: 17 | 8-M6×1, length: 12 | 8-45° | 22.5° | 12 |

*The input/output shaft keyways are old JIS standard class 2 while the key is old JIS standard class 1. Note that the keyway dimensions of the unit hub part do not conform to JIS standards. Check them on the dimensions table above.

*When inserting pulleys or the like onto input/output shafts, use the supplied insertion set.

*The 121-25-20G base is a casting.

Related Product

Basic Specifications

- Brake torque 2.4 N・m to 10 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

Basic Specifications

- Brake unit torque 2 N・m to 15 N・m

- Motor output 0.2 kW to 1.5 kW (4-pole)

- Operating temperature -10℃ to 40℃

Basic Specifications

- Brake torque 0.4 N・m to 2.4 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

Basic Specifications

- Clutch/brake torque 5 N・m to 40 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어