![]()

Features of BEW(FH) Models

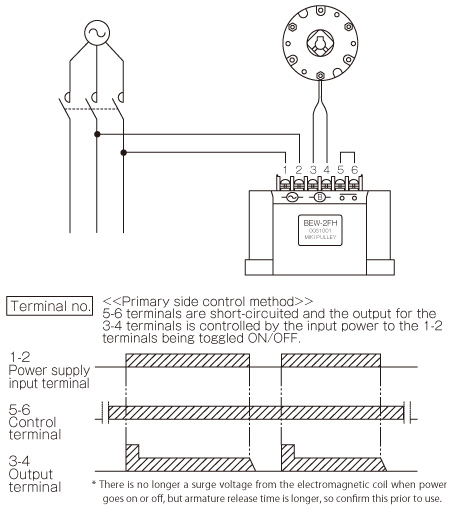

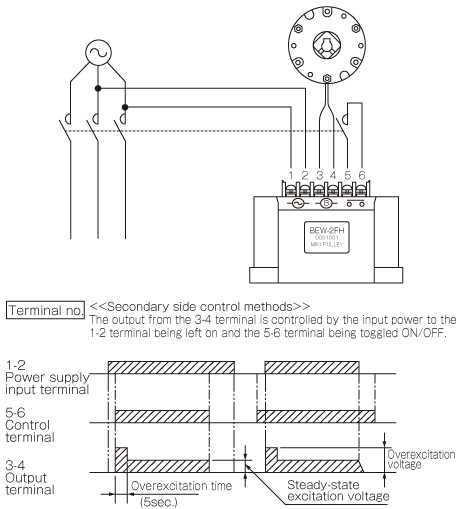

These are compact, high-capacity overexcitation power supplies that can be used in the full range of electromagnetic clutches and brakes of rated voltage 45 V DC/90 V DC/180 V DC.Using these as overexcitation power supplies provides benefits such as longer (roughly double) service lives for electromagnetic clutches and brakes and shorter (roughly halved) armature pull-in times. Using these as weak excitation power supplies provides benefits such as lower power consumption (roughly one-quarter), suppressed heat generation (roughly one-quarter) in the stator (electromagnetic coil), and shorter armature release times.

Related Product

Basic Specifications

- Brake torque 5 N・m to 320 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

Basic Specifications

- Input voltage AC_100 V, AC 200 V, AC 400 V

- Output voltage DC 45 V, DC 90 V, DC 180 V

- Operating temperature -10℃ to 60℃

Basic Specifications

- Clutch torque 0.4 N・m to 2.4 N・m

- Operating temperature -10℃ to 40℃

- Backlash Zero

Basic Specifications

- Clutch torque 17.5 N・m to 2200 N・m

- Operating temperature 0℃ to 40℃

- Backlash Zero

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어