What are the different types of robots and what are their structures? A veteran instructor with 48 years of technical experience explains!

What are the different types of robot?

What is a robot?

Ms. Hama: Mr. Hashimoto! The other day, I saw a special edition of an industry magazine devoted to factory automation.

I was surprised to see so many robots working in factories! Could you tell us about the sorts of robot that are being used around the world?

Mr. Hashimoto:I see. OK. Today, let’s learn all about robots. We’ll start by looking at the definition.

■Definition of robot

In the “2014 White Paper on Robotization of Industry, Business and Our Life” produced by the New Energy and Industrial Technology Development Organization (NEDO) in March 2014, robots are defined as “intelligent mechanical systems equipped with the three component technologies of sensors, intelligence/control systems and drive systems.”

Ms. Hama: So, various different technologies are integrated in robots. What exactly are the different types of robot?

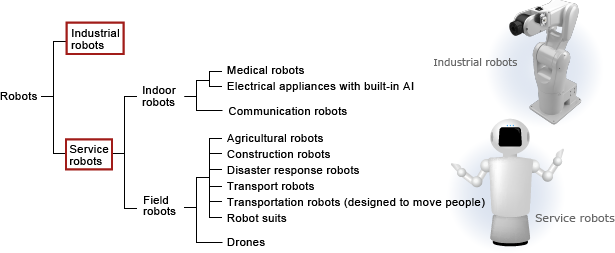

“Industrial robots” and “service robots”

Mr. Hashimoto: We can broadly classify robots into industrial robots and service robots. Robots used to automate industry are called “industrial robots”, and robots used to assist us in everyday life are called “service robots”.

■Types of robot

Ms. Hama: Gee, there are so many types! Earlier, when I saw robots working in factories in the magazine, I saw that they were classified as “industrial robots”. What sorts of work are industrial robots best suited to?

Types of industrial robots and their features

Mr. Hashimoto:Industrial robots are each suited to different types of work. We have to choose the type of robot that is best for the specific task.

| Types | Number of axes | Applications | Features | Range of movements | Speeds | Precisions |

|---|---|---|---|---|---|---|

Cartesian coordinate robots |

2~4 | Parts assembly | These are industrial robots with a simple construction that combines single-axis units with linear motion. They can only move in straight lines, but units can be combined flexibly to suit the intended application. | - | ○ | ○ |

| Articulated robots (vertical multi-joint type)  |

4~7 | Welding, Coating, Assembly | These are currently the most widely used industrial robots. Shaped with arm-like appendages, these robots have great freedom of movement and are capable of reaching around objects. They are extremely versatile and are used in a wide range of industrial processes, from transportation through to welding, coating and assembly. | ○ | - | - |

Dual-arm robots |

2~4 | Handling inspection, Assembly | These models are capable of movements not possible using a single-arm robot, such as holding boxes from both sides. They can perform very difficult and precise tasks in a limited space. | ○ (Flexible) |

- | - |

| SCARA robots (horizontal multi-joint type)  |

4 | Electrical machinery component insertion, assembly, etc. | These industrial robots feature arms that operate horizontally. They have a 4-axis construction that makes them highly rigid in the vertical plane while being highly flexible in the horizontal plane. SCARA robots are widely used in assembly processes (plugging in components, etc.) in the electrical machinery sector. | - | ○ | - |

| Parallel robots (parallel links)  |

4~6 | High-speed pick&place | These are industrial robots that use parallel mechanisms (a method for controlling the movement of a single point via multiple parallel links). While they have a low weight capacity, they are highly suited to high-speed operations. Parallel robots are installed in locations such as above a conveyor belt and used for very fast pick-and-place operations on moving products. | - | ○ | ○ |

Ms. Hama:I saw lots of robots at last year’s International Robot Exhibition 2019! The robot used differs depending on the application. So, in the table, what does it mean by “number of axes”?

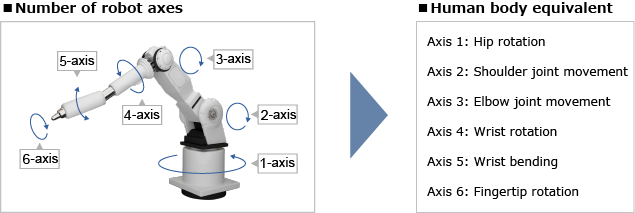

Mr. Hashimoto:That’s a very good question. The number of axes indicates how many joints the robot has. It’s an important factor in determining the robot’s movements. This term is crucial to understanding a robot’s structure, so I’ll explain this next.

What sorts of structures do industrial robots have?

Industrial robots have the same structure as people

Mr. Hashimoto:The basic structure of an industrial robot consists of robot arms combined with joints and linkages. In terms of the human body, these joints are like the elbow or shoulder, which can move around freely, and the links are like the bones that connect them.

Ms. Hama: It’s because we have joints that we can move our bodies in various directions. The same is true for industrial robots. The more axes (joints) they have, the more sections they have that can move freely.

How many axes do industrial robots have?

Mr. Hashimoto:For instance, in the case of vertically articulated robots, which are capable of complex movements, they generally have 6 joints (6 axes, 6 degrees of freedom). If we look at the equivalent in the human body, it looks like this.

Ms. Hama: It’s easy to understand when you try moving your body!

I’d like to hear more about the sorts of mechanisms industrial robots use to move around.

What elements are important to robot movement?

An explanation of the essential elements of industrial robots

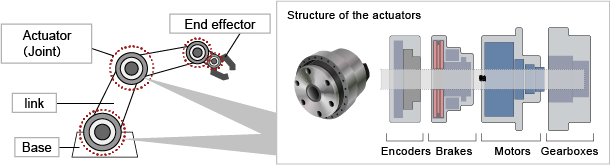

Mr. Hashimoto: The key elements that make up a robot can be broadly divided into 3 categories.

1. Mechanical elements (structures, mechanisms, drive components, sensor housings, etc.)

2. Electronic circuits (drive circuits, sensor circuits, microprocessors, computer circuits)

3. Software (control, information processing, decision-making, etc.)

Today, let’s look in more detail at the mechanical elements.

The mechanical elements that are particularly important in an industrial robot are actuators (joints), gearboxes, sensors, emergency brakes and power transfer mechanisms.

■Essential elements of robots

| Elements | Purposes | Products used |

|---|---|---|

| Actuators | Used for rotating the arm and moving it up, down left and right. Built into the robot’s joint section |

|

| Gearboxes | Used to obtain the power for robot movement. Because the power of the motor alone is not sufficient, it is combined with a gearbox to obtain more power. |

|

| Sensors | Used as necessary to detect factors such as acceleration, torque, pressure, temperature and the encoders used to detect the rotary axis position and speed |

|

| Emergency brakes | If there is a power failure or outage, these immediately stop the robot’s movement. | |

| Power transfer mechanisms | Used to transfer gearbox output to the operating tip |

|

Ms. Hama: I was amazed to see that gearboxes, sensors and brakes are all built into the small joints (actuators) in industrial robots! I guess this is possible because the individual elements are all getting smaller and lighter.

This makes me eager to learn even more about industrial robots!

Mr. Hashimoto, Miki Pulley Co., Ltd

Joined Miki Pulley in 1972. Worked as a Product Manager in the Marketing and Technology divisions in positions both in Japan and overseas. He has also been involved with other organizations through joint research projects with universities and specialist bodies. He currently works in technical guidance and staff training.

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어