ETP BUSH

Original hydraulic system connects with a single bolt

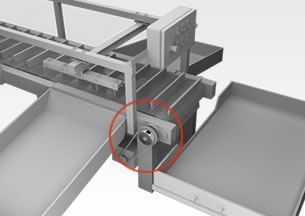

Our original hydraulic system connects with a single bolt. The shaft and hub are coupled by friction without use of keys, so the shortcomings and difficulties of key couplings are solved all at once. Its construction is simple, mounting and removal are easy, and it can accurately position and index. This greatly reduces work from the design stage to assembly, calibration, and maintenance. ,It can be mounted using a single bolt, and many models are available, including the ETP-T, which meets a concentricity of 0.006 mm.

* ETP is a registered trademark of ETP Transmission AB.

- 製品一覧

- アプリケーション

- カスタマイズ

- よくあるご質問

- ムービー

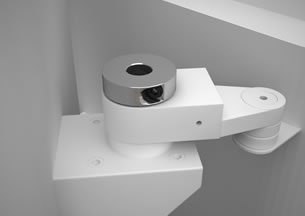

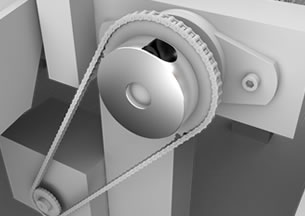

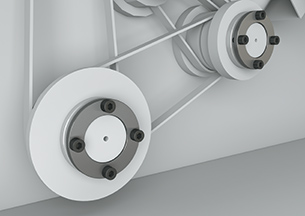

The axle and hub are connected by a single bolt, so installation can be done quickly and easily. Moreover, the concentricity is an excellent 0.02mm, so it is perfect for places where high precision is required and it will be frequently removed and installed. It is built to tighten radially, so it does not need a lot of space to operate.

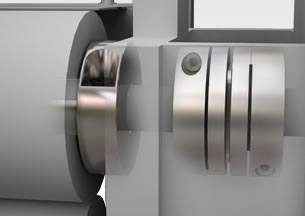

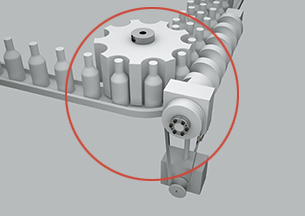

The shaft and hub can be easily and quickly coupled using a single pressure screw.This facilitates assembly of equipment that requires positioning in the rotation and axial directions. It is also effective in locations requiring repeated mounting and removal. The concentricity of the shaft and hub is 0.006 mm, so ultra-precise positioning is possible as well.

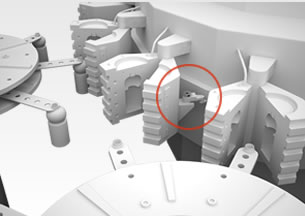

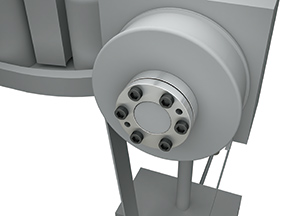

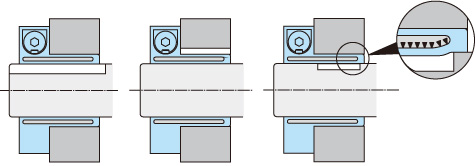

Shaft and hub can be easily and quickly coupled by tightening a clamping bolt located on the flange surface.Fastening is accomplished using fewer bolts than with mechanical systems, and there is no slotting as with mechanical systems, so high-precision coupling with a concentricity of 0.05 mm is possible.

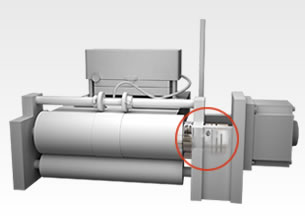

Shaft and hub are strongly coupled by pumping oil into the sleeve under pressure to move the wedge of the built-in taper piston.The oil used for coupling is only necessary for moving the piston, so after coupling is achieved, the pressure is released and the taper piston is held in place by the wedge effect.

日本語

日本語 English

English Deutsch

Deutsch 中文

中文 한국어

한국어